Elevator device for restraining vibration of tractor and elevator

A traction machine and anti-vibration device technology, which is applied to elevators in buildings, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of traction machine vibration amplification, building vibration increase, traction machine overturning, etc. problem, to achieve the effect of suppressing vibration, avoiding resonance and avoiding overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

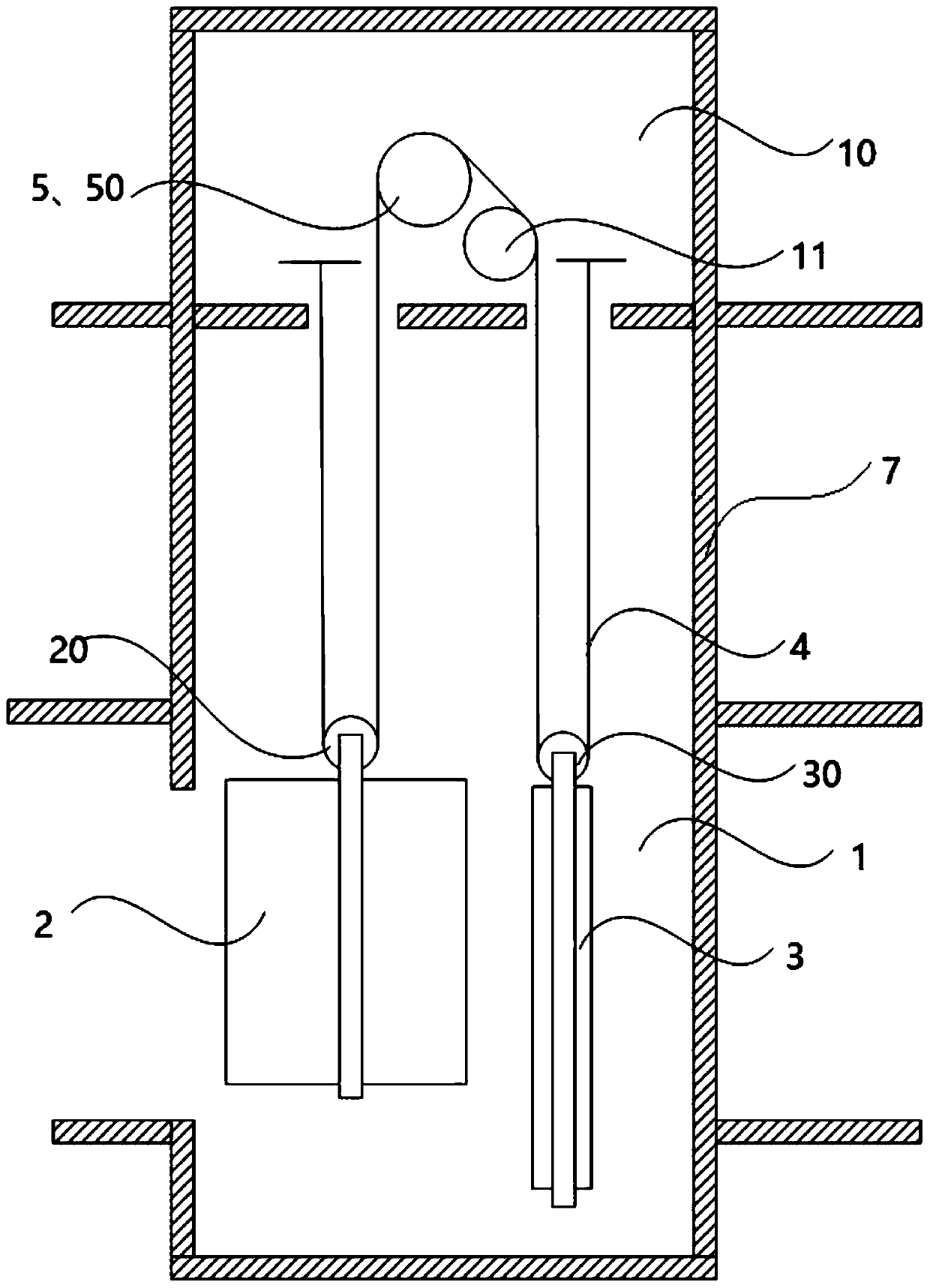

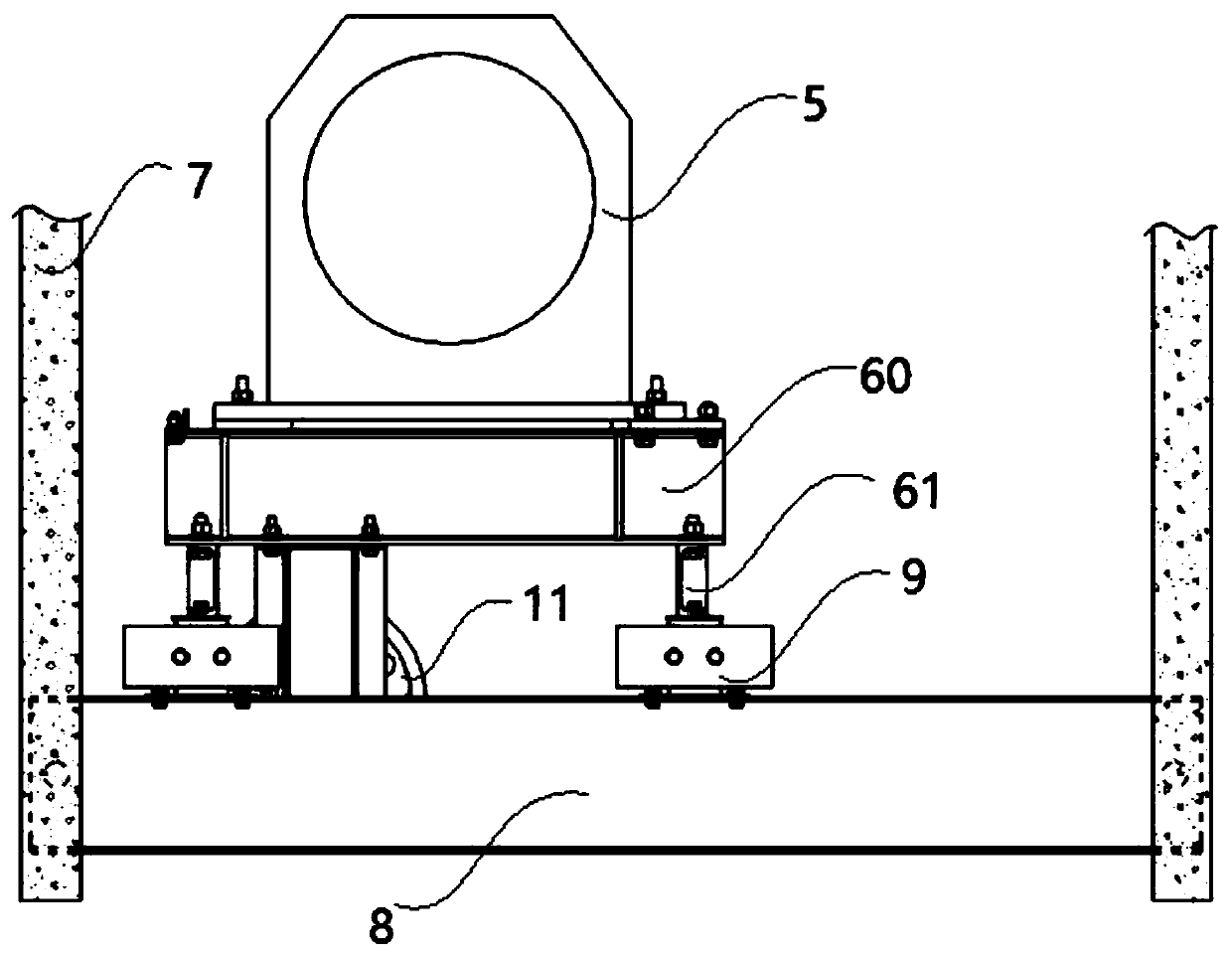

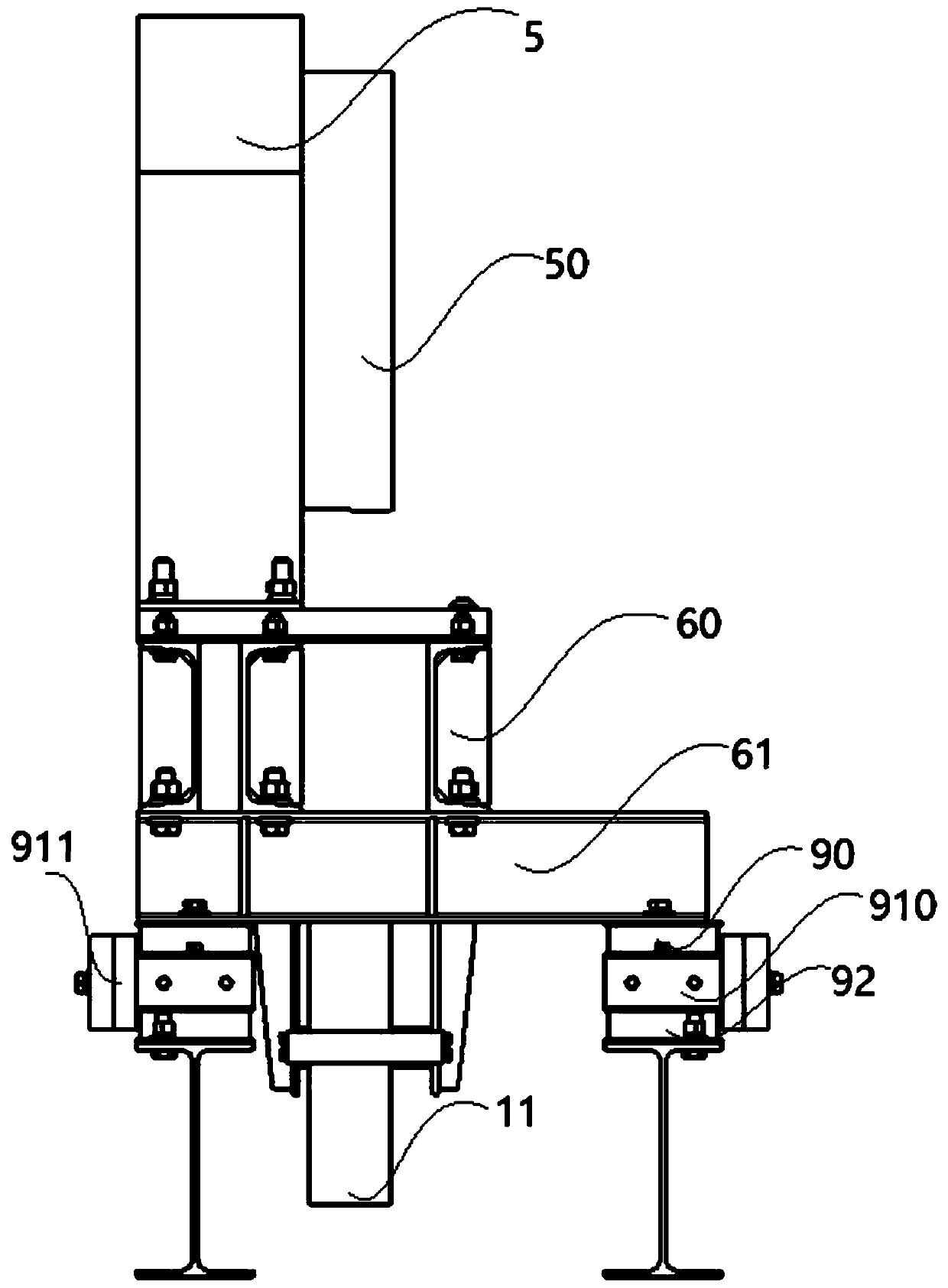

[0051] The present invention provides an elevator device for suppressing the vibration of the traction machine. The elevator device comprises a hoistway 1, an elevator car 2, a counterweight 3, a steel wire rope 4, a traction machine 5, and a base 6 fixed at the lower end of the traction machine 5. 1. The load-bearing beam 8 fixed between the building walls 7 at both ends and at least one anti-vibration device 9 fixed between the base 6 and the load-bearing beam 8 are used to suppress the vibration of the traction machine 5. It is characterized in that the anti-vibration Vibration device 9 comprises:

[0052] An upper elastic layer 90, the upper elastic layer 90 includes:

[0053] A first upper plate 900, the center of the first upper plate 900 is fixedly connected to the base 6 by bolts;

[0054] A first elastic body 901, the first elastic body 901 is fixed on the lower end of the first upper plate 900;

[0055] An intermediate quality layer 91, the intermediate quality layer...

Embodiment 2

[0074] In this embodiment, on the basis of the first embodiment above, the upper elastic layer 90, the middle mass layer 91 and the lower elastic layer 92 are split, and the upper elastic layer 90 also includes a second lower plate 902 fixed on the first elastic The lower end of the body 901 is used to connect the first elastic body 901 and the first mass body 910;

[0075] The lower elastic layer 92 also includes a second upper plate 922 fixed on the lower end of the first mass body 910 for connecting the first mass body 910 with the second elastic body 920 .

[0076] The second upper plate 922 includes a second internal thread seat 9220 for fastening the second upper plate 922 and the first mass body 910 with bolts.

[0077] Specifically, such as Figure 5 As shown, the upper elastic layer 90, the middle mass layer 91 and the lower elastic layer 92 are split, and the upper elastic layer 90 also includes a second lower plate 902, which is fixed to the lower end of the first ...

Embodiment 3

[0081] In this embodiment, on the basis of the first embodiment above, the upper elastic layer 90, the middle mass layer 91, and the lower elastic layer 92 are integrated, and the first elastic body 901 is preliminarily combined with the first mass body by casting or bonding. The upper end of the mass body 910 is fastened, and the second elastic body 920 is pre-fastened to the lower end of the first mass body 910 by casting or bonding.

[0082] Specifically, such as Figure 6 As shown, the difference between the third embodiment and the second embodiment above is that the upper elastic layer 90, the middle mass layer 91 and the lower elastic layer 92 are integrated, that is, the second lower part of the upper elastic layer 90 in the second embodiment above The plate 902 and the second upper plate 922 in the lower elastic layer 92 can be removed, and the first elastic body 901 and the first mass body 910 can be fastened in advance and the first mass body 910 can be connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com