Scroll compressor and air conditioner adopting scroll compressor

A technology for scroll compressors and air conditioners, which is applied in the field of compressors, can solve problems such as liquid impact damage to parts of the pump body, and achieve the effect of improving the operation reliability of the whole machine and reducing the risk of liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

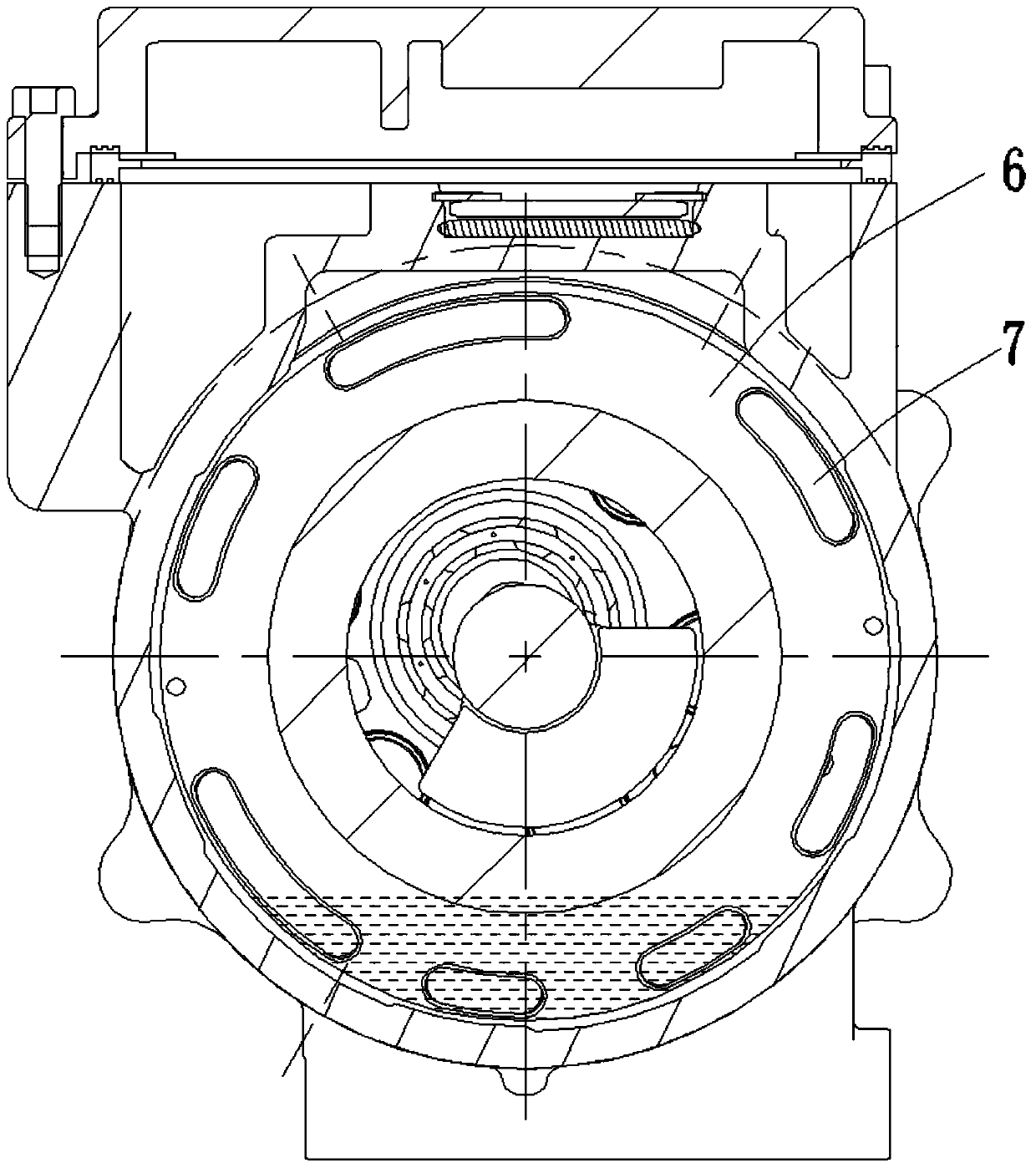

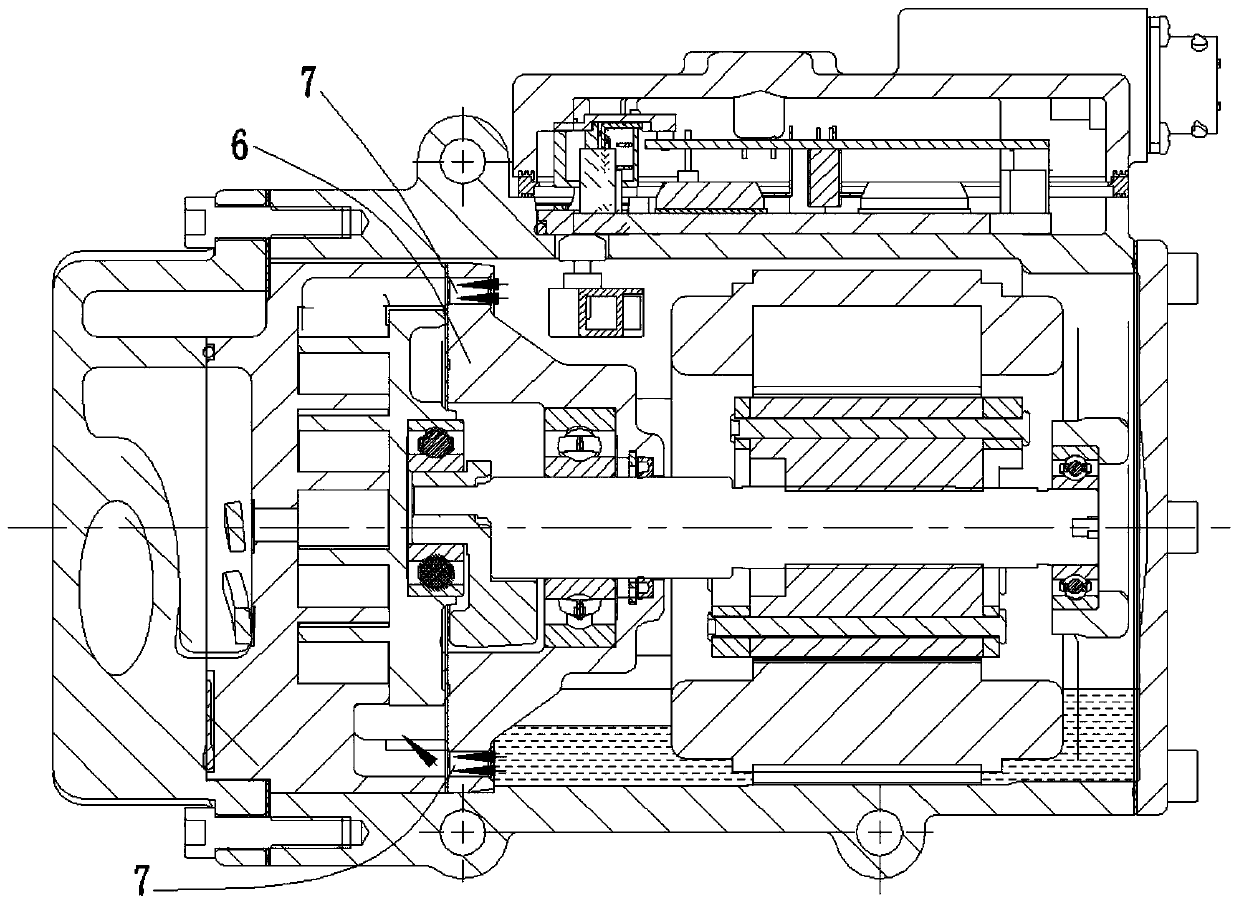

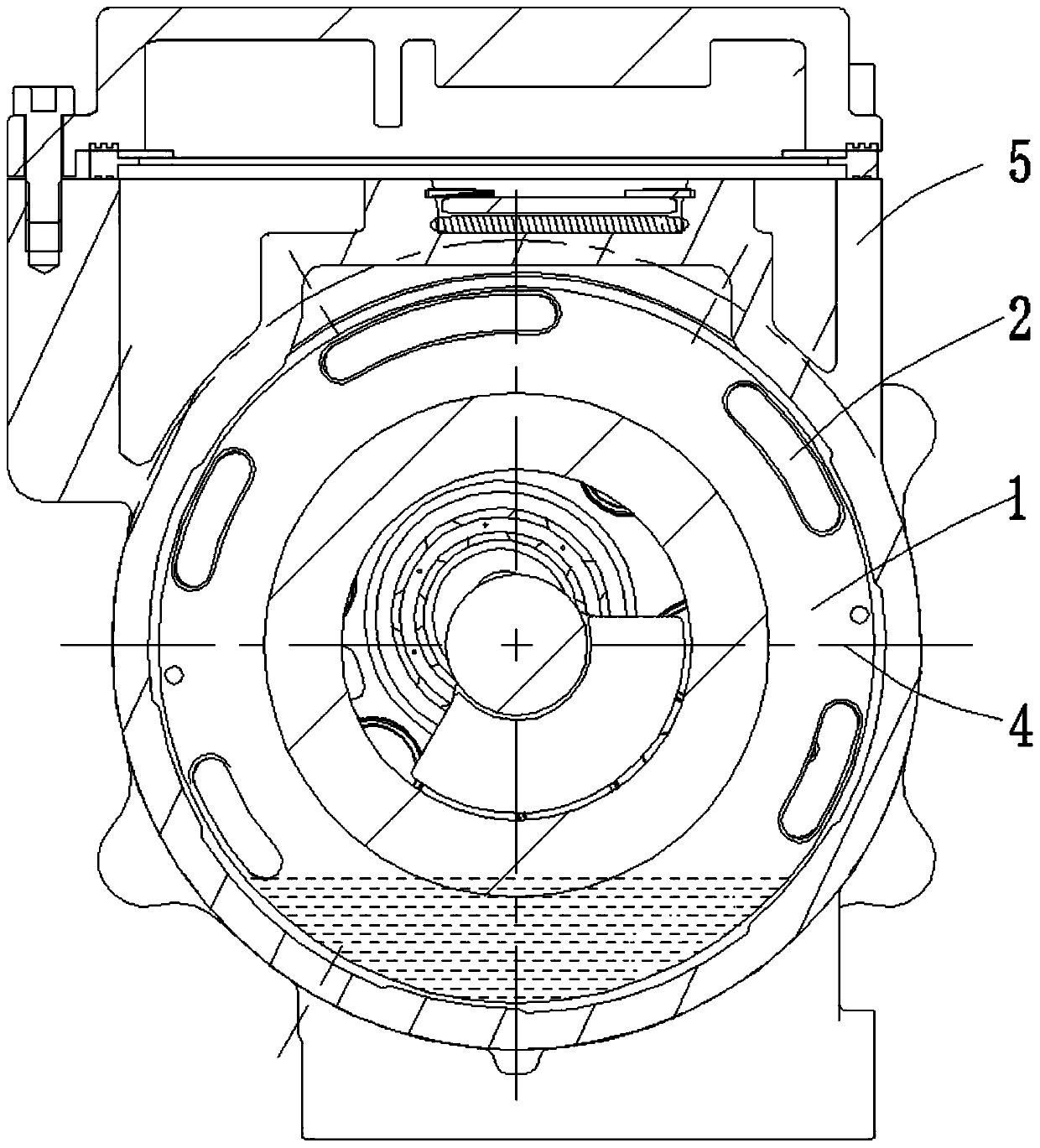

[0036] A scroll compressor, by rationally designing the gas-liquid channel of the bracket, the risk of liquid absorption in the pump body is greatly reduced, and the operation reliability of the whole machine is improved, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, specifically set to the following structure:

[0037] The scroll compressor introduced in this embodiment is obtained by improving the gas-liquid channel 2 on the basis of the existing scroll compressor.

[0038] Among them, unless otherwise specified, the opening area of the gas-liquid passage is directly related to the air intake capacity. For the convenience of description, the existing gas-liquid passage 7 in this embodiment is an equal-diameter flow channel, and the following is also used as an equal-diameter flow channel for the vortex. Referring to the rotary compressor, the opening area of the gas-liquid channel 2 directly represents its air intake capacity, and the larg...

Embodiment 2

[0042] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0043]When the gas-liquid channel 2 is located above the liquid level of the refrigerant between the bracket 1 and the motor in the casing 5, in order to ensure the oil return lubrication of the pump body, at least one through oil return hole 3 is provided on the end surface of the bracket 1 . Generally speaking, in order to basically ensure the lubrication of the scroll compressor during operation, the oil return hole 3 should be at least partly below the liquid level of the refrigerant during operation of the compressor. Further, in order to make better use of the suction channel for oil return lubrication of the pump body, the number of oil return holes 3 can be appropriately increased according to the actual situation. The number is generally 1-10, and the specific number can b...

Embodiment 3

[0048] This embodiment is further optimized on the basis of embodiment 1 or 2, and further for better realization of the present invention, particularly adopts the following configuration structure:

[0049] Through the simulation test of multiple working conditions, it is concluded that the possible height of the liquid refrigerant is H, and the relationship between H and the diameter φ of the inner cavity of the shell satisfies: φ / 10<H<φ / 2. Then, the lowest opening height of the gas-liquid channel 2 is denoted as H1, and H1 satisfies: φ / 10≤H1≤φ / 2, wherein φ is the diameter of the inner cavity of the housing. Under this setting, it can be basically guaranteed that when the scroll compressor is running, the gas-liquid passage 2 is located above the lowest level of the refrigerant liquid level, so as to reduce the suction of liquid refrigerant by the pump body.

[0050] Preferably, in order to better adapt to different working conditions of different compressors, the H1 satisfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com