Defect detection method based on image grayscale features

A defect detection and image grayscale technology, applied in the field of visual inspection, can solve the problems of high price, high external environment requirements, high imaging quality requirements, etc., and achieves low imaging quality requirements, good real-time performance, and shortened detection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

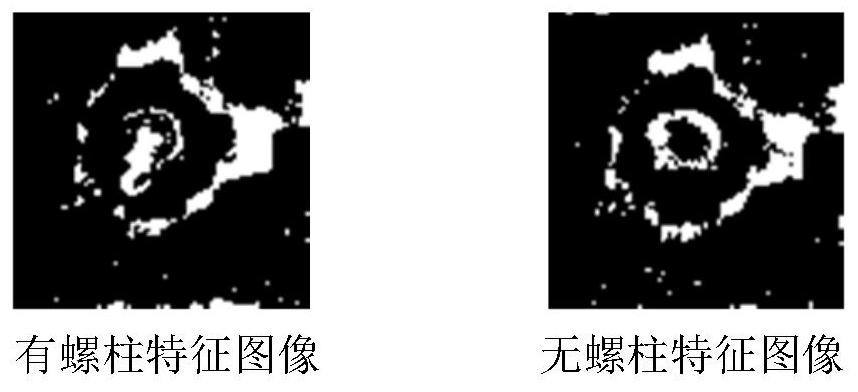

[0041] A defect detection method based on image grayscale features, such as figure 1 As shown, this implementation takes welding stud detection as an example to identify whether there is a stud at a specific position of the workpiece. If there is a stud, the position is considered normal (corresponding to a normal feature), and if there is no stud, the position Abnormal (corresponding to defect characteristics);

[0042] Specific steps are as follows:

[0043] 1) Extract the region of interest of the measured image of the workpiece to be tested, obtain the feature region image and perform the following steps on it, and obtain the global feature vector corresponding to the feature region image

[0044] ① Grayscale the image to obtain a grayscale image;

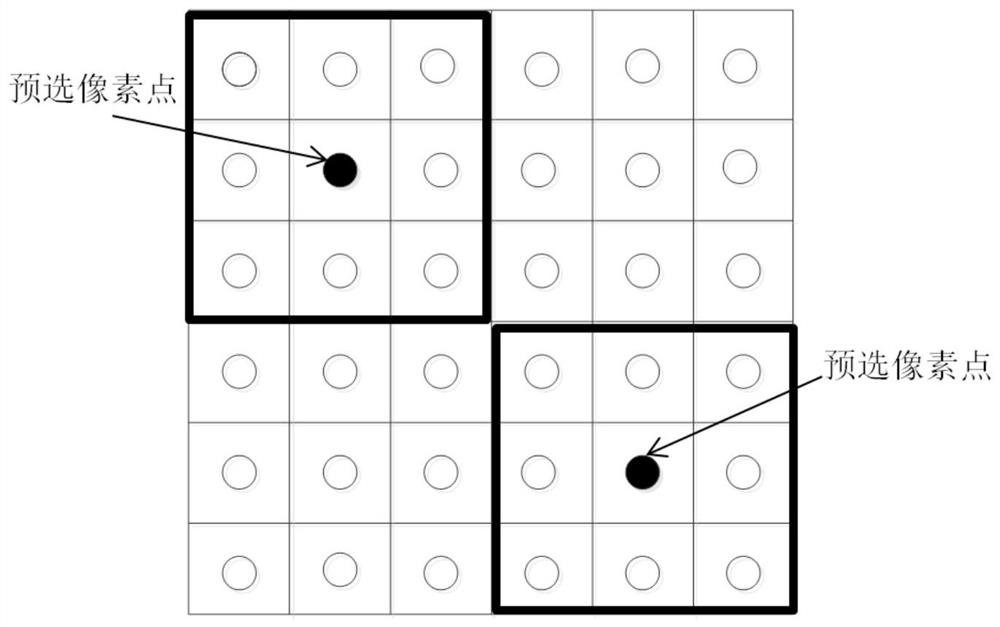

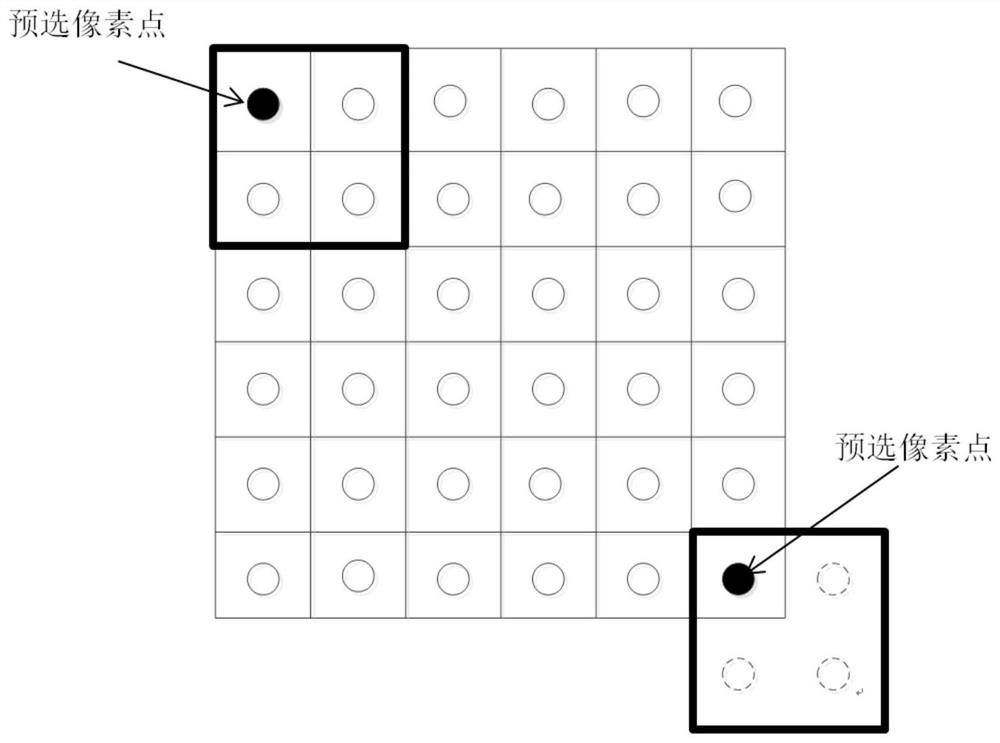

[0045] ②Starting from the pre-selected pixels in the grays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com