Clamper for robot paintbrush

A technology of robots and clamps, applied to instruments, educational tools, teaching models, etc., can solve problems such as breaking, shrinkage, and inaccurate motion track data, and achieve the effect of quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

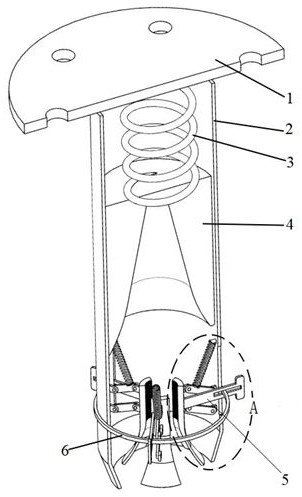

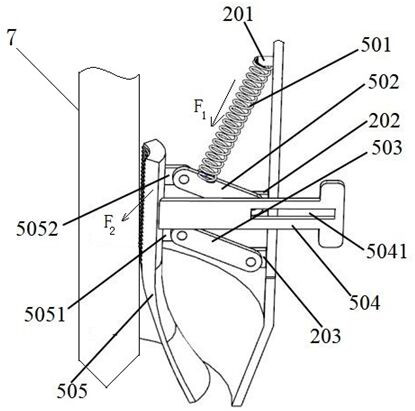

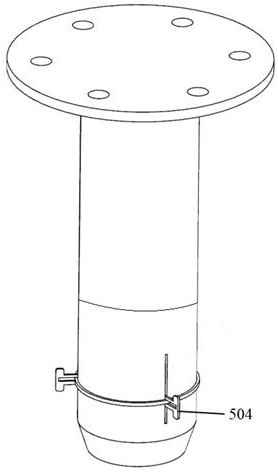

[0027] see figure 1 , figure 2 , image 3 , Figure 4 .

[0028] A clamper for a robot paintbrush according to the present invention comprises a flange cover 1;

[0029] Pen container 2, the top surface of the pen container 2 is welded or bonded to the bottom surface of the flange cover 1;

[0030] Spring A3, sleeve 4, and sleeve 4 are slidably installed inside the pen container 2, and the two ends of spring A3 are respectively in contact with or bonded to flange cover 1 and sleeve 4, and the middle part of sleeve 4 is provided with a tapered mounting bracket for paintbrush 7. hole;

[0031] A plurality of buffer clamping mechanisms 5, a plurality of buffer clamping mechanisms 5 for clamping a paintbrush 7 are fixedly installed on the bottom of the pen holder 2.

[0032] In order to realize the buffering and clamping functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com