Agricultural furrowing device

A technology of agriculture and knife handle, which is applied in agriculture, excavation/covering ditches, applications, etc. It can solve the problems of limited use and inconvenient control of ditch depth, so as to avoid shaking and offset, facilitate storage and save money. The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

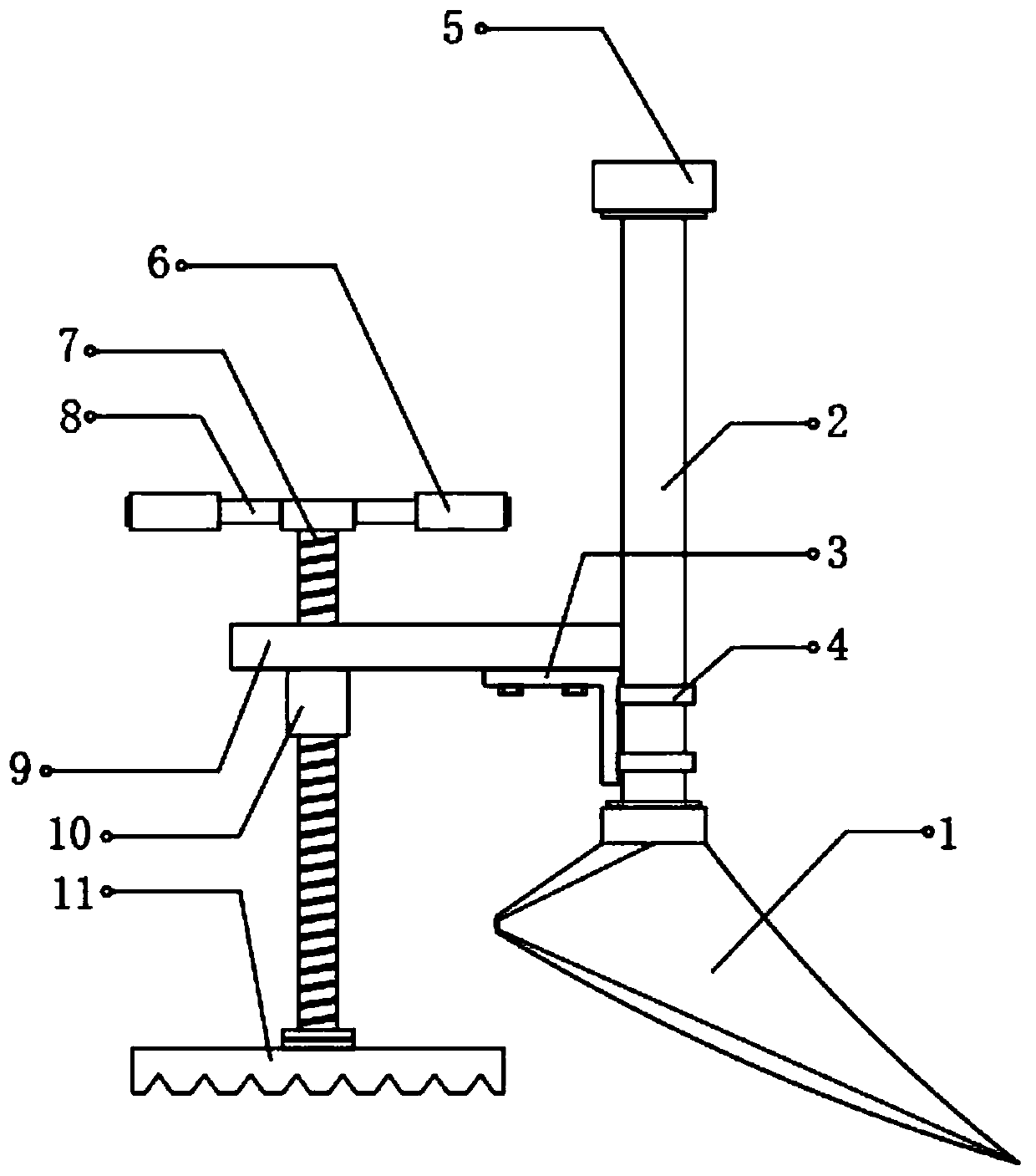

[0026] refer to figure 1 , an agricultural ditching device, comprising a coulter 1 and a handle 2, the coulter 1 is welded to the bottom of the handle 2, a fixing plate 9 is welded to the bottom of one side of the handle 2, and the fixing plate 9 is far away from the handle 2 One side of the screw rod 7 is threadedly connected, and the bottom of the screw rod 7 is connected with a pressing plate 11 through bearing rotation, and the bottom of the pressing plate 11 is provided with evenly distributed grooves, and both sides of the top of the screw rod 7 are welded with the first rotating rod 8 , and the ends of the two first rotating rods 8 away from the screw rod 7 are sleeved with the first handle 6, the handle 2 is installed on the driving mechanism, and the driving mechanism drives the coulter 1 to carry out ditching, and is held by the first handle 6 Hold the first rotating rod 8, rotate the screw rod 7, and then adjust the distance between the pressing plate 11 and the gro...

Embodiment 2

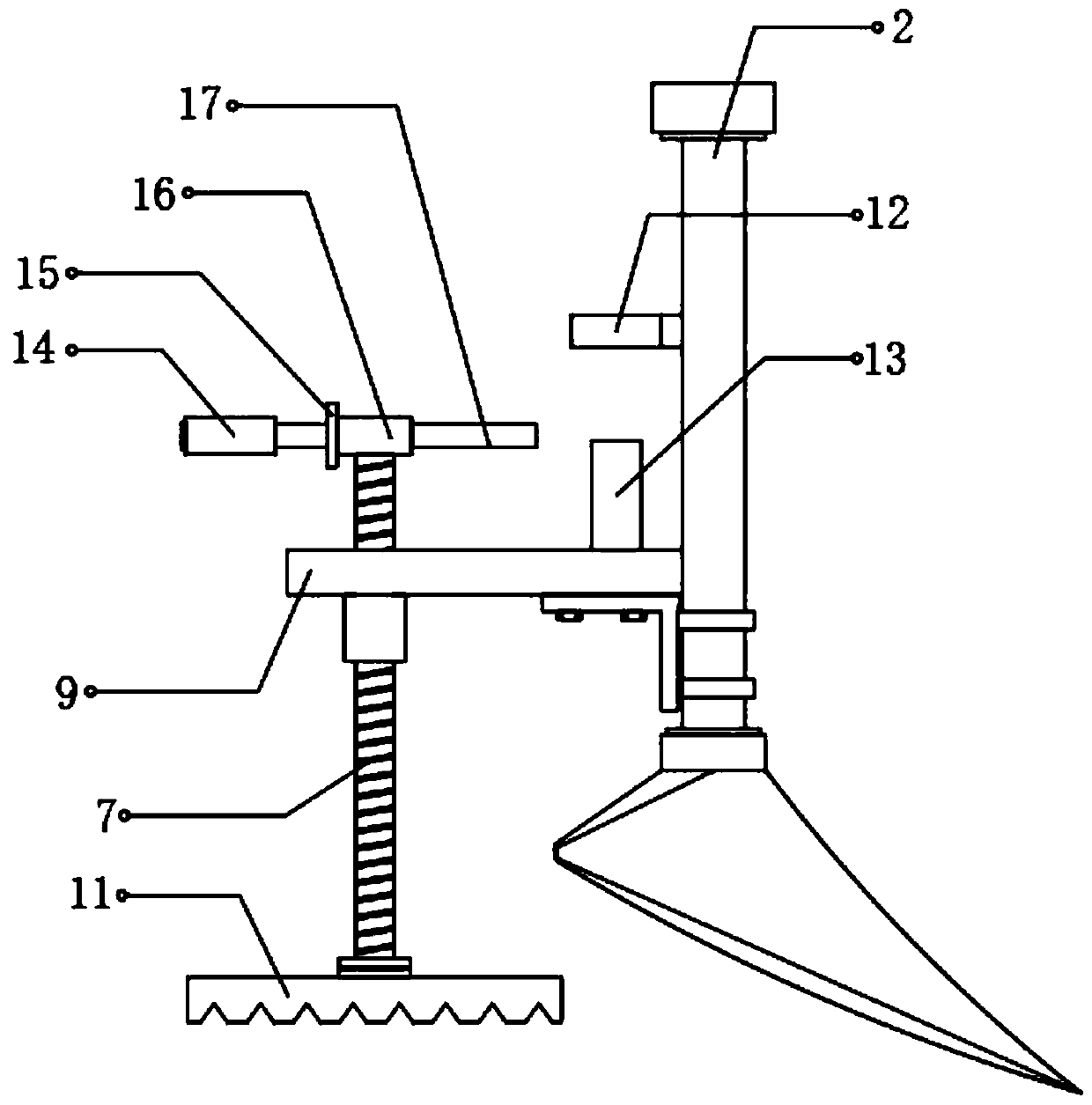

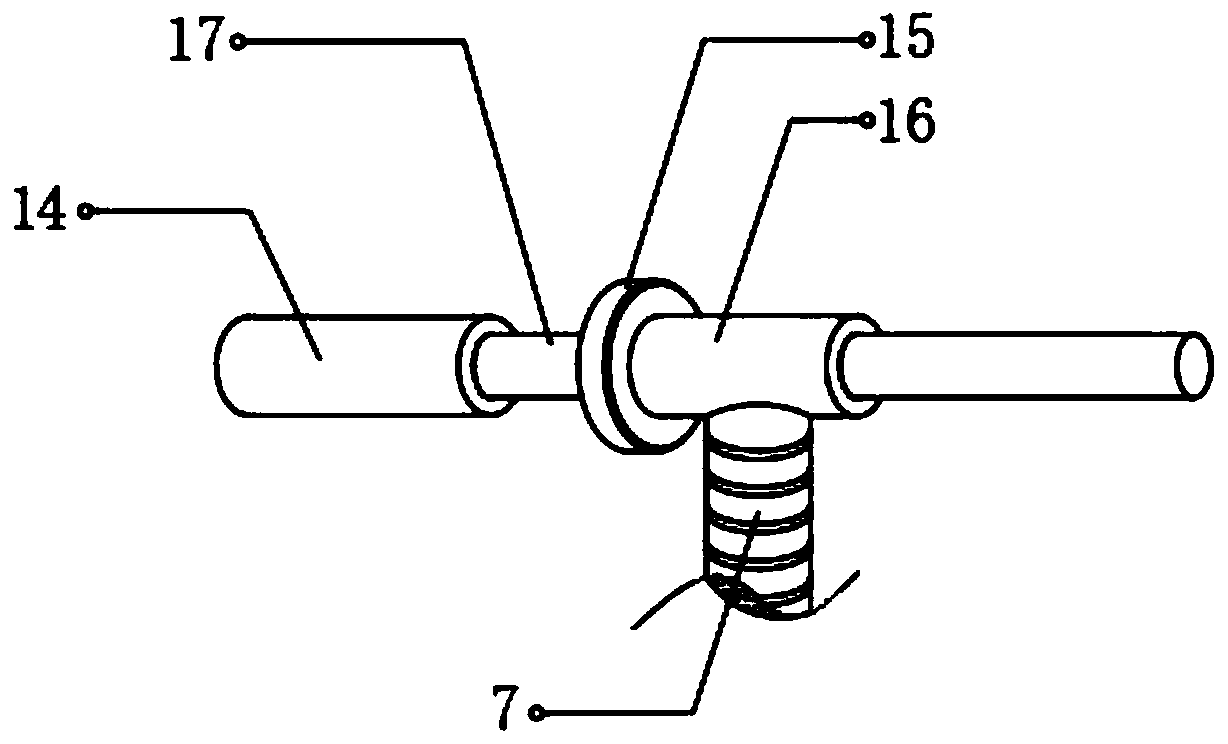

[0032] refer to image 3 , an agricultural ditching device. Compared with Embodiment 1, the first rotating rod 8 is replaced by the second rotating rod 17 in this embodiment, and the top of the screw rod 7 is welded with a socket 16, and the second rotating rod 17 is plugged in Inside the insertion sleeve 16, one end of the second rotating rod 17 is sleeved with a second handle 14, and one side of the second rotating rod 17 is welded with a limiting ring 15, and one side of the limiting ring 15 is connected to the side of the inserting sleeve 16. The sides are in contact, the middle part of the knife handle 2 near the side of the fixed plate 9 is welded with an insert ring 12 , and the top of the fixed plate 9 near the side of the knife handle 2 is welded with a fixed sleeve 13 .

[0033] Working principle: the second rotating rod 17 is held by the second handle 14, and the screw rod 7 is rotated, the second rotating rod 17 can be drawn out from the insertion sleeve 16, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com