Ship ballast water treatment system and treatment method based on barge or wharf

A technology for treating system and ballast water, which is applied in the direction of pipelines, hulls, and ship construction for emptying/ballasting, which can solve the problems of discharge pollution, high power consumption, and poor adaptability of ballast water, etc., and achieve reduction Pollution, processing speed will not decrease, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the drawings and specific embodiments.

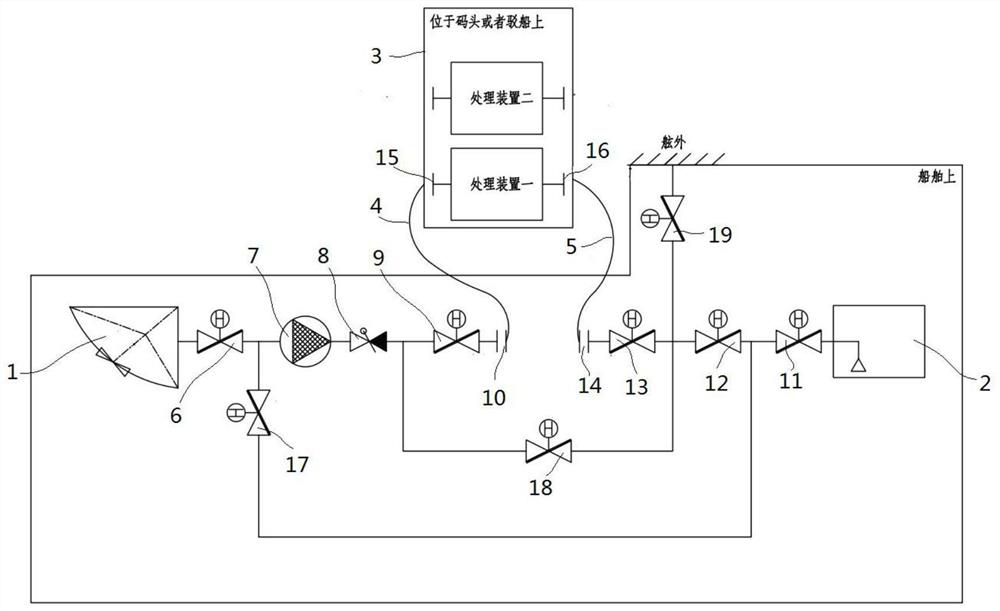

[0019] like figure 1 As shown, a ship ballast water treatment system based on a barge or a wharf proposed by the present invention includes a seawater tank 1 and a ballast tank 2 arranged on the ship; pipeline and de-ballast pipeline; at least one set of processing device 3 is provided in the ballast pipeline, and the processing device 3 is connected to the ballast pipeline through a first hose 4 and a second hose 5; The processing device 3 is fixed on a wharf or a barge.

[0020] The present invention is further provided as follows: the ballast pipeline includes a valve one 6 connected to the water outlet end of the seawater tank 1 through a pipeline, and the other end of the valve one 6 is connected to a ballast pump ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap