Method for producing high-quality metallurgical coke by using non-caking coal

A technology for the production of metallurgical and non-caking coal, which is applied in coking ovens and the petroleum industry, and can solve problems such as low coke strength, failure to meet metallurgical coke indicators, and no mention of coke thermal strength, sulfur and ash indicators, etc. Achieve the effect of reducing coke cost, improving economic and social benefits, and expanding coking coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Shenmu non-caking coal is selected, wherein Mt is 12 mass%, sulfur St is 0.24 mass%, ash Ad is 4.5 mass%, volatile Vdaf is 36.0 mass%, and G value is 0.

[0037] Coal blending according to the scheme in Table 1 below, wherein scheme 1 is not equipped with non-caking coal, and based on the total mass of all raw coal used, scheme 2 and scheme 3 are respectively equipped with 3% and 6% non-caking coal.

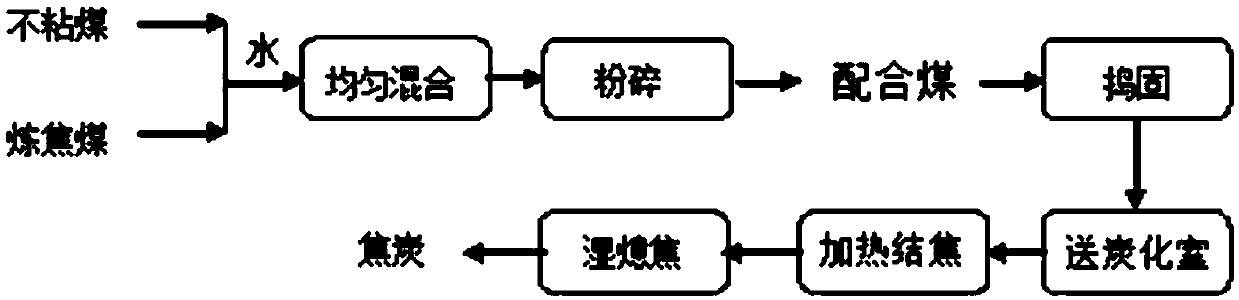

[0038] according to figure 1 Method Mix the non-caking coal and coking coal evenly with water, crush it into blended coal with a fineness of 91.3%, and then tamp the blended coal to a bulk density of 1.1t / m3 , into the coke oven carbonization chamber, isolated from the air and heated to 1000±50°C, the coking time is 25h, and the coke is quenched by wet method. Table 2 and Table 3 are respectively the coal index and price of each scheme and the coke quality index of each scheme.

[0039] Table 1 Test plan

[0040]

[0041] Table 2 Coal indicators and prices of various ...

Embodiment 2

[0047] Shenmu non-caking coal is selected, Mt is 12 mass%, sulfur St is 0.24 mass%, ash Ad is 4.5 mass%, volatile Vdaf is 36.0 mass%, and G value is 0.

[0048] According to the coal blending scheme in Table 4 below, based on the quality of all raw coal used, scheme 4 and scheme 5 are respectively equipped with 6% and 10% non-caking coal.

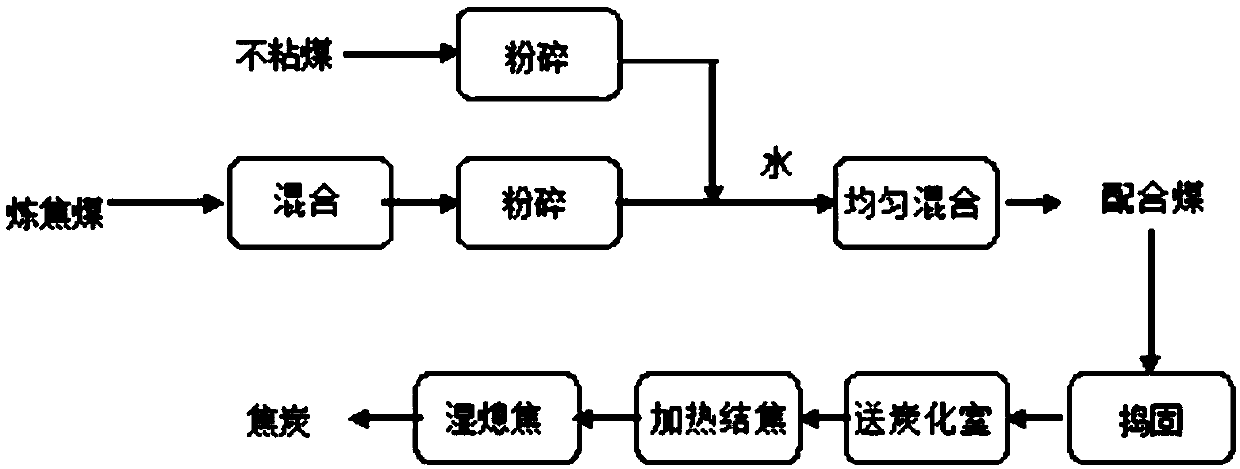

[0049] according to figure 2 The method is to crush the non-caking coal to a fineness of 88.7%, wherein the mass ratio of the crushed non-caking coal with a particle size of less than 0.5-3mm is 83.5%; to mix and crush two or more other coking coals to a fineness of 88.5%; Mix pulverized non-caking coal with pulverized coking coal and add water to obtain blended coal, and then tamp the blended coal to a bulk density of 1.1t / m 3 , into the coke oven carbonization chamber, isolated from the air and heated to 1000±50°C, the coking time is 25h, and the coke is quenched by wet method. Table 5 and Table 6 respectively show the matching coal in...

Embodiment 3

[0058] Shenmu non-caking coal is selected, Mt is 12 mass%, sulfur St is 0.24 mass%, ash Ad is 4.5 mass%, volatile Vdaf is 36.0 mass%, and G value is 0.

[0059] Coal blending according to the scheme in Table 7 below, based on the quality of all raw coal used, scheme 6 and scheme 7 are respectively equipped with 10% and 15% non-caking coal.

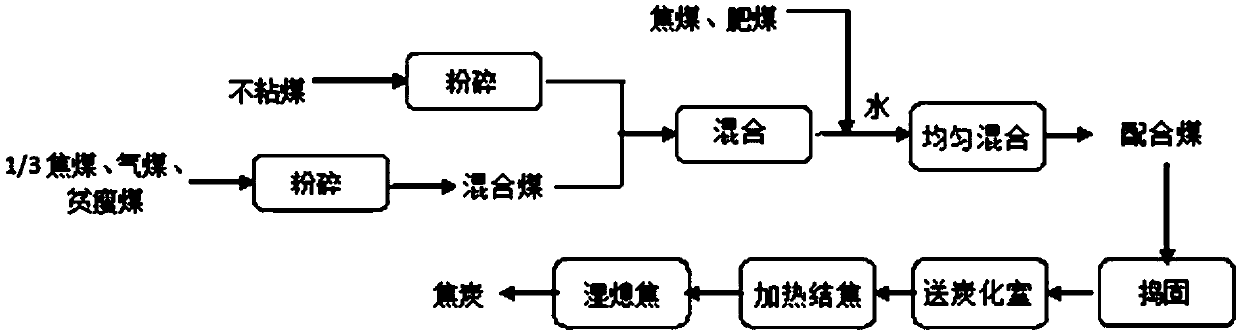

[0060] according to image 3 The method is to crush the non-caking coal to a fineness of 90.5%; crush 1 / 3 coking coal and lean coal to a mixed coal with a fineness of 89.6%; mix the two, and then mix them with coking coal and fat coal and add water to obtain blended coal ; and tamping the blended coal to a bulk density of 1.1t / m 3 , into the coke oven carbonization chamber, isolated from the air and heated to 1000±50°C, the coking time is 25h, and the coke is quenched by wet method. Table 8 and Table 9 respectively show the matching coal index and price of each scheme and the coke quality index of each scheme.

[0061] Table 7 Test plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com