Disc spraying device

A shower and disc technology, applied in the field of showers, can solve the problems of small spray area, non-uniformity, and small flow area of the tower, so as to improve the processing capacity, save the manufacturing cost, and ensure the flow area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

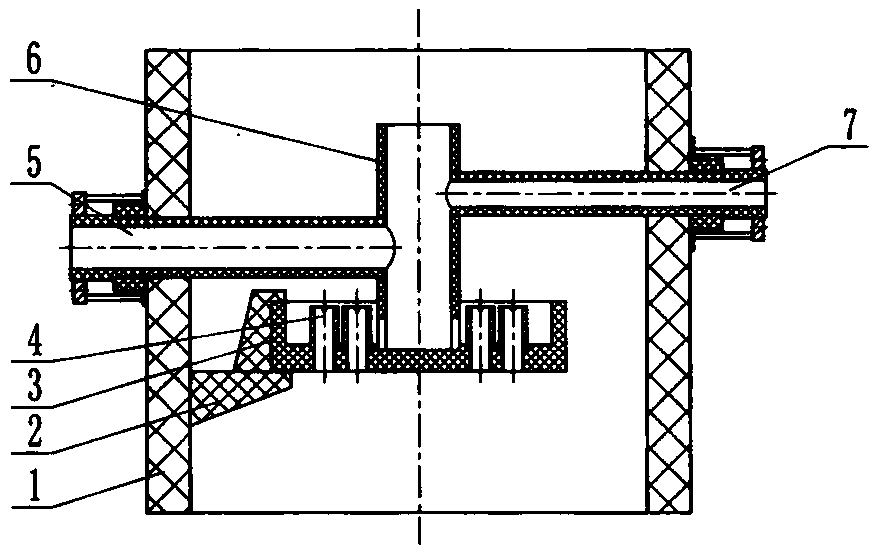

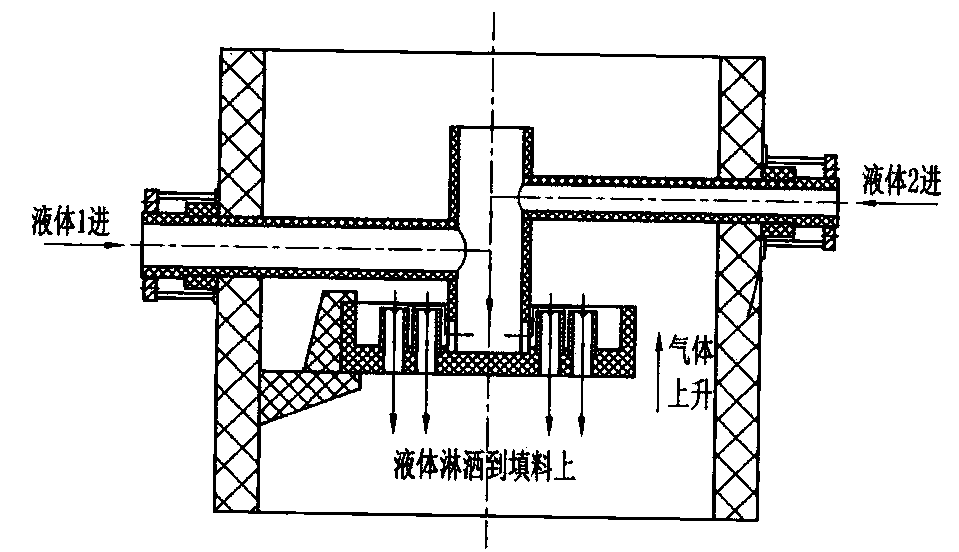

[0013] A disc shower, comprising a support 2 arranged on the inner wall of a tower body 1, a distribution disc 3 is arranged on the support, the support places the distribution disc in the center of the tower body, and a vertical inlet is arranged on the distribution disc. Liquid pipe 6, the vertical liquid inlet pipe is connected with the horizontal liquid inlet pipe, and a plurality of evenly distributed overflow pipes 4 are arranged on the distribution plate and the outer periphery of the vertical liquid inlet pipe, and the top of the overflow pipe is lower than the height of the outer edge of the distribution plate , The overflow pipe is a shower channel through which the liquid is showered onto the filler.

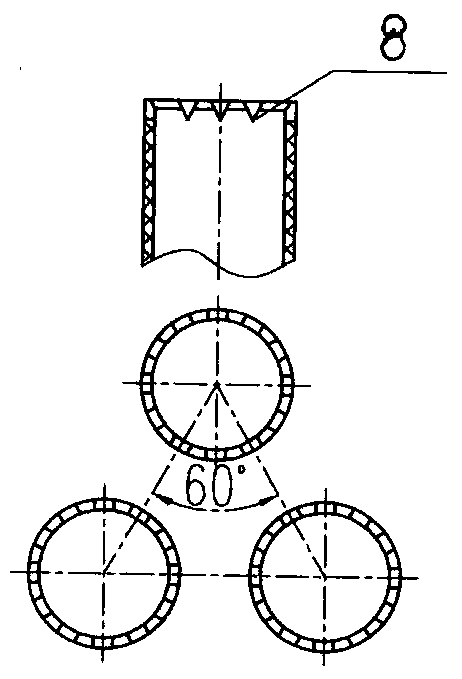

[0014] The tooth mouth 8 is arranged on the top of each overflow pipe, and the function is to ensure that the liquid enters evenly. There are 1-multiple horizontal liquid inlet pipes.

[0015] The liquid enters the distribution plate from the liquid inlet pipe, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com