An experimental method for heat transfer of supercritical water and carbon dioxide mixed working medium

A carbon dioxide, mixed working fluid technology, applied in the direction of thermal development of materials, thermal conductivity of materials, etc., can solve the problems of difficult to achieve steady-state conditions, consuming manpower and material resources, and difficult to operate, avoiding current cross-flow, saving energy, improving The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

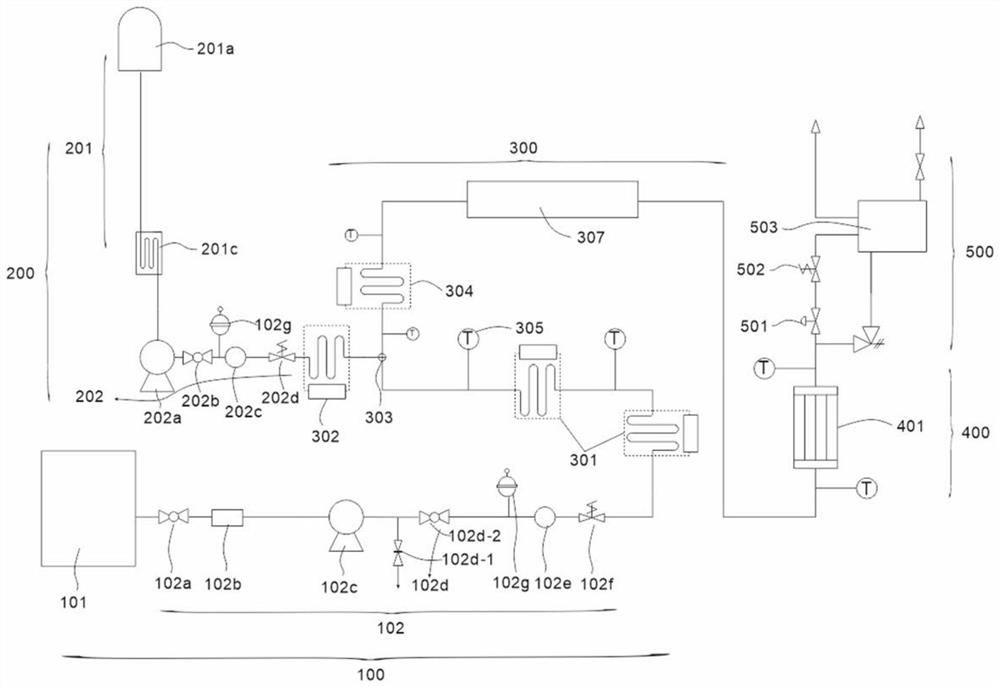

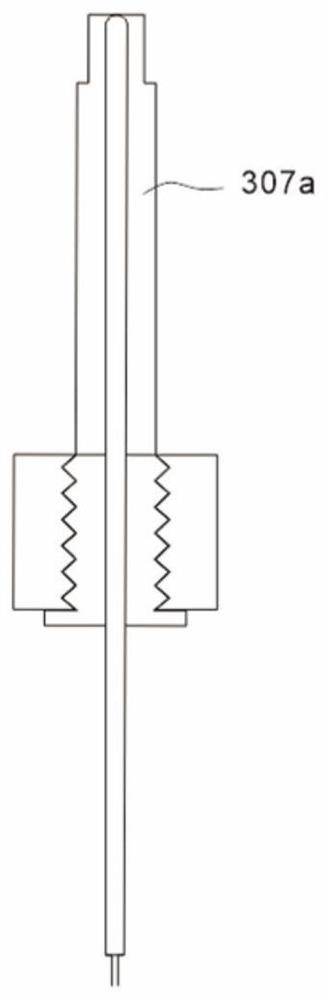

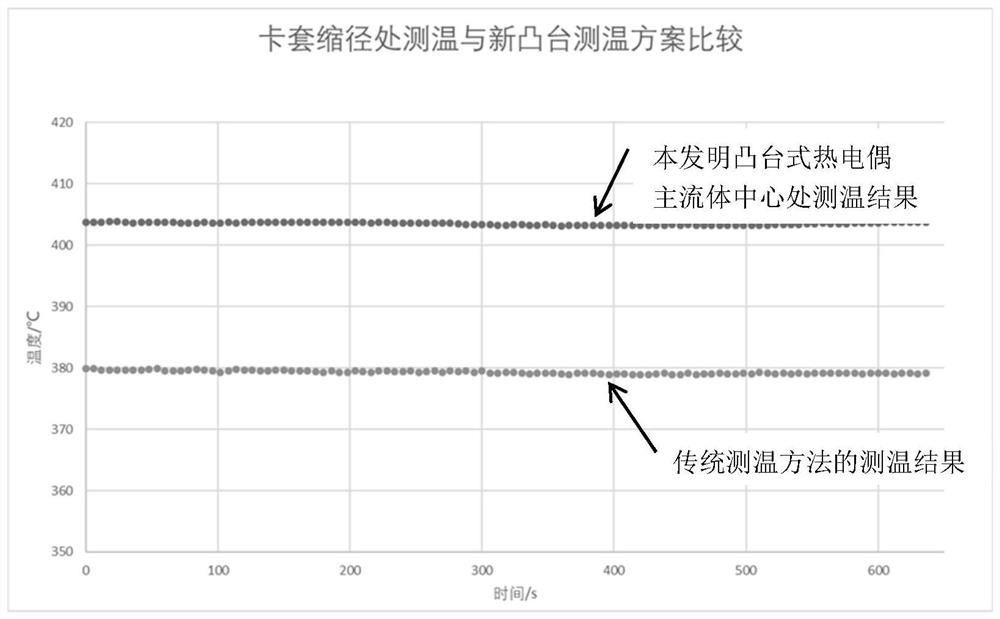

[0044] As an embodiment of the experimental method of supercritical water and carbon dioxide mixed working fluid heat transfer described in the present invention, such as figure 1 As shown, the experimental method of supercritical water and carbon dioxide mixed working medium heat transfer includes water supply: realized by the water supply unit 100, wherein the working medium water in the water storage tank 101 flows through the first control assembly 102 connected thereto; for carbon dioxide: Realized by the carbon dioxide supply unit 200, wherein the working medium carbon dioxide in the carbon dioxide liquefaction supply assembly 201 flows through the second control assembly 202 connected thereto; mixing and heating: realized by the preheating mixing unit 300, wherein the water supply unit 100 The working medium water is preheated by the first preheating component 301, the working medium liquid carbon dioxide in the carbon dioxide unit 200 is preheated by the second preheati...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, the carbon dioxide liquefaction supply assembly 201 includes a carbon dioxide gas cylinder 201a connected in sequence, a third control assembly 201b, a carbon dioxide liquefaction supply tank 201c, and a refrigerant for cooling the carbon dioxide liquefaction; the third control assembly 201b controls Carbon dioxide is passed into the carbon dioxide liquefaction supply tank 201c from the carbon dioxide cylinder 201a.

[0058]preferred, such as Figure 6 As shown, the carbon dioxide liquefaction supply tank 201c includes a refrigerant inlet 201c-1 located at the bottom of the carbon dioxide liquefaction supply tank 201c, which is located inside the carbon dioxide liquefaction supply tank 201c and connected to the refrigerant inlet 201c-1. 1 connected cooling coil 201c-2, a refrigerant outlet 201c-3 located on the side wall of the carbon dioxide liquefaction supply tank 201c and commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com