Trilateral tape wrapping machine and working method thereof

A wrapping machine and wrapping technology, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve the problems of inability to achieve three-layer wrapping, easy to slip, loose traction, etc., to facilitate control and increase friction. , the effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

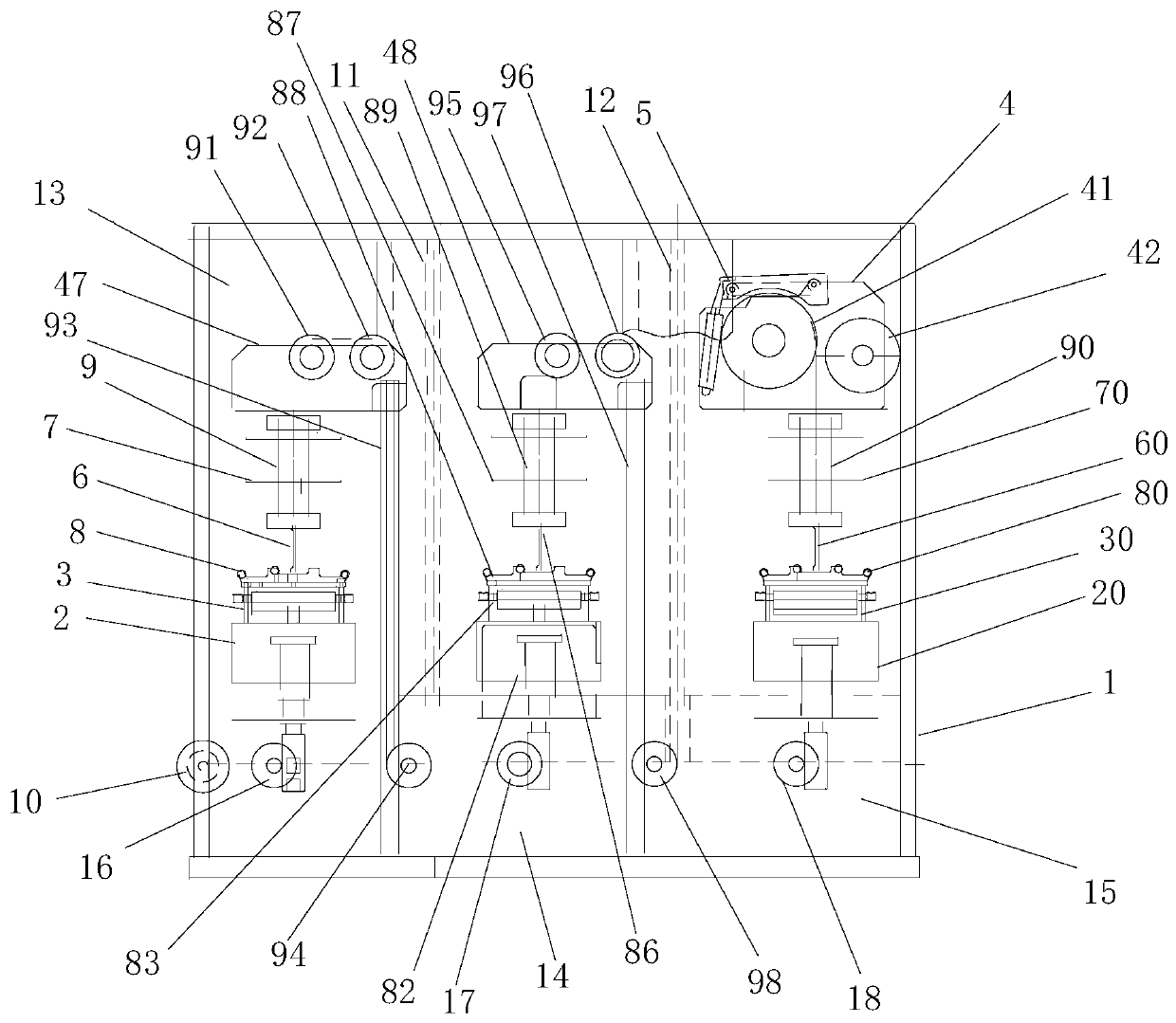

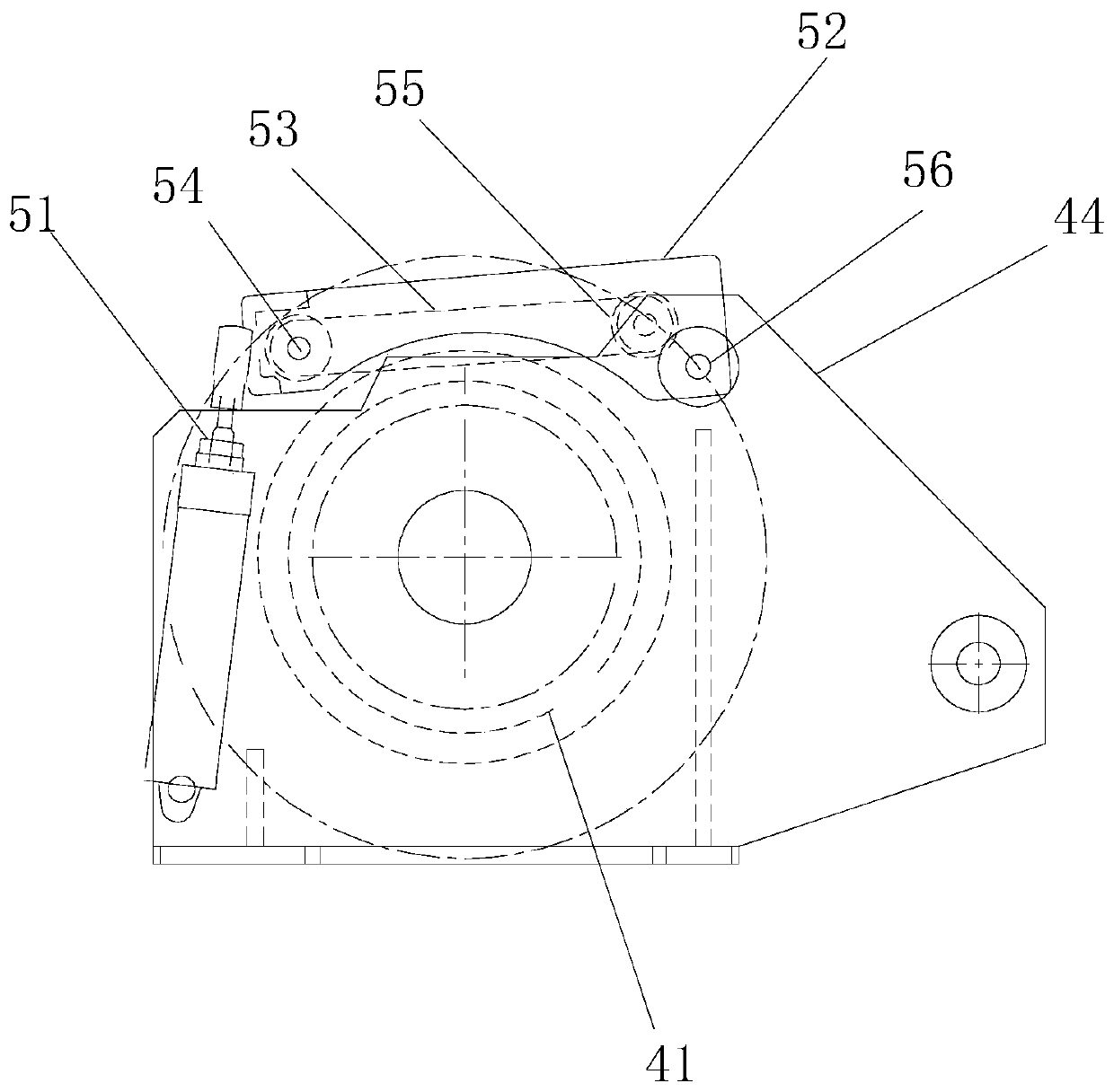

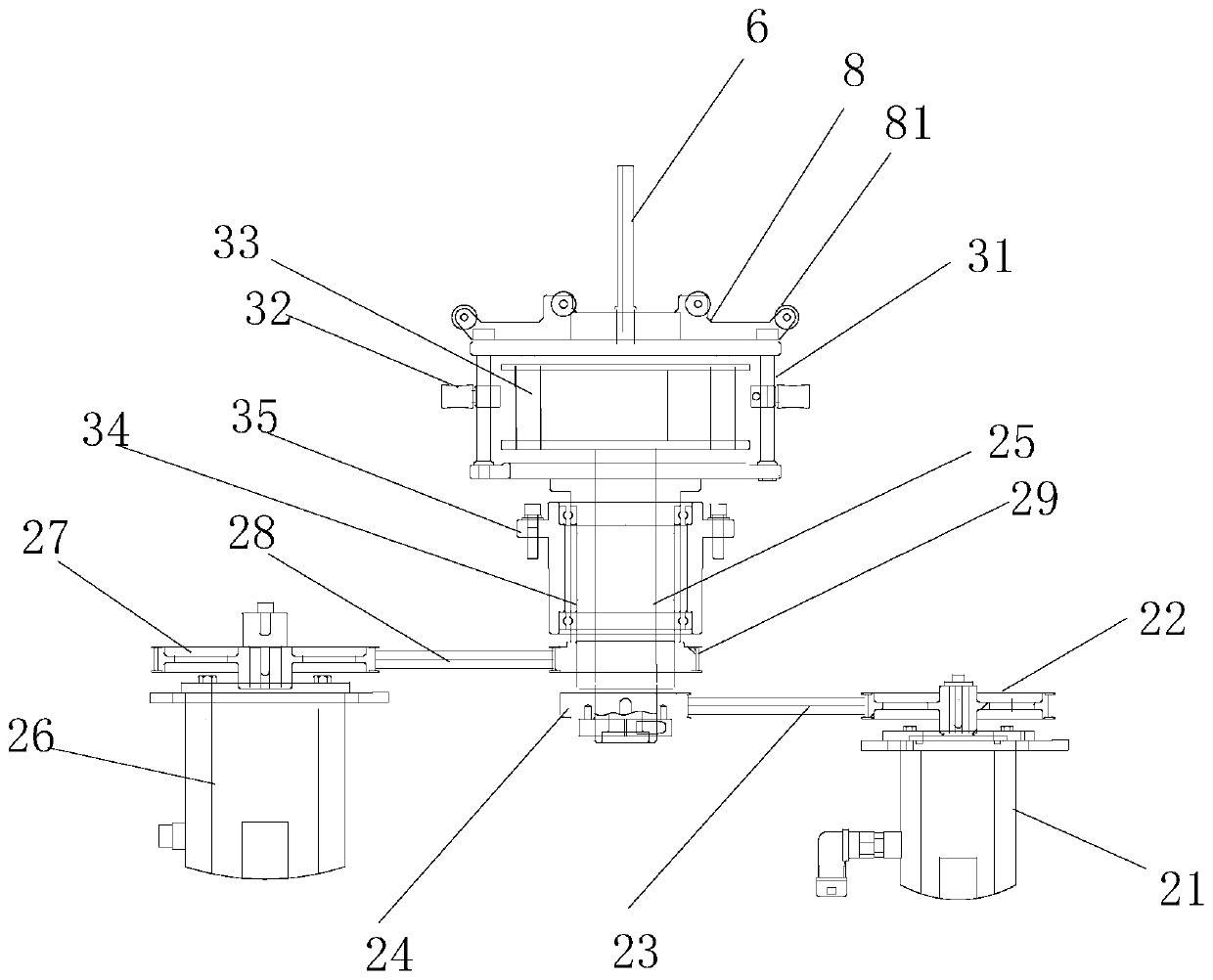

[0038] Example 1 as figure 1 As shown, the three-side tape wrapping machine of this embodiment includes a cabinet body 1, a first wrapping unit, a first turning guide wheel assembly, a second wrapping unit, a second turning guide wheel assembly, a third wrapping unit, The traction device 4 and the belt pressing device 5, the inside of the cabinet 1 are provided with a first partition 11 and a second partition 12 in parallel, for separating the cabinet 1 into a left chamber 13, a middle chamber 14 and a right chamber Chamber 15, the left chamber 13, the middle chamber 14 and the right chamber 15 are provided with cabinet doors respectively, the first wrapping unit is placed in the left chamber 13, the second wrapping unit is placed in the middle chamber 14, and the second wrapping unit is placed in the middle chamber 14. Three wrapping units are placed in the right chamber 15, so that the first wrapping unit, the second wrapping unit, and the third wrapping unit are arranged si...

Embodiment 2

[0056] The working method of the above-mentioned three-side taping machine comprises the steps:

[0057] A. Remove the first roller frame 8 of the first wrapping unit, the second roller frame 88 of the second wrapping unit, and the third roller frame 80 of the third wrapping unit, which will be used for the whole wrapping The roll covering tape is placed on the tension disc 33 of the first wrapping unit, the second wrapping unit, and the third wrapping unit, and the spare whole roll of covering tape is placed on the first coil storage rack 7, The second coil storage rack 87, on the third coil storage rack 70; the first roll guide frame 8 of the first wrapping unit, the second guide roll frame 88 of the second wrapping unit, the third wrapping unit The third guide roller frame 80;

[0058] B. The first layer of wrapping: the core material to be wrapped is introduced into the tension shaft 25 of the first wrapping unit through the first wire guide wheel 16 of the first wrapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com