Display panel and display device

A technology of display panel and display area, applied in the direction of diodes, semiconductor devices, electrical components, etc., can solve the problem of intrusion into the evaporation film layer, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

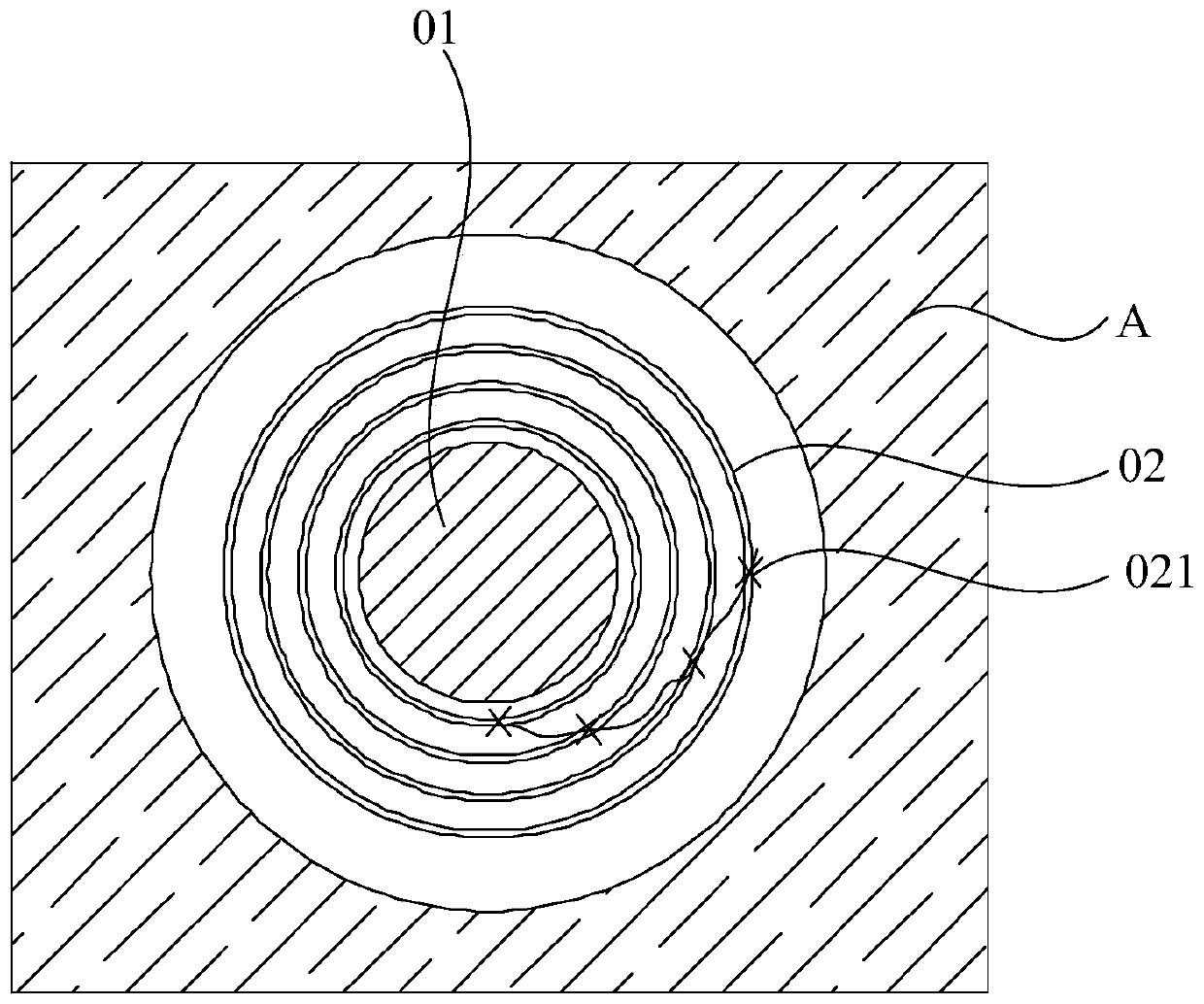

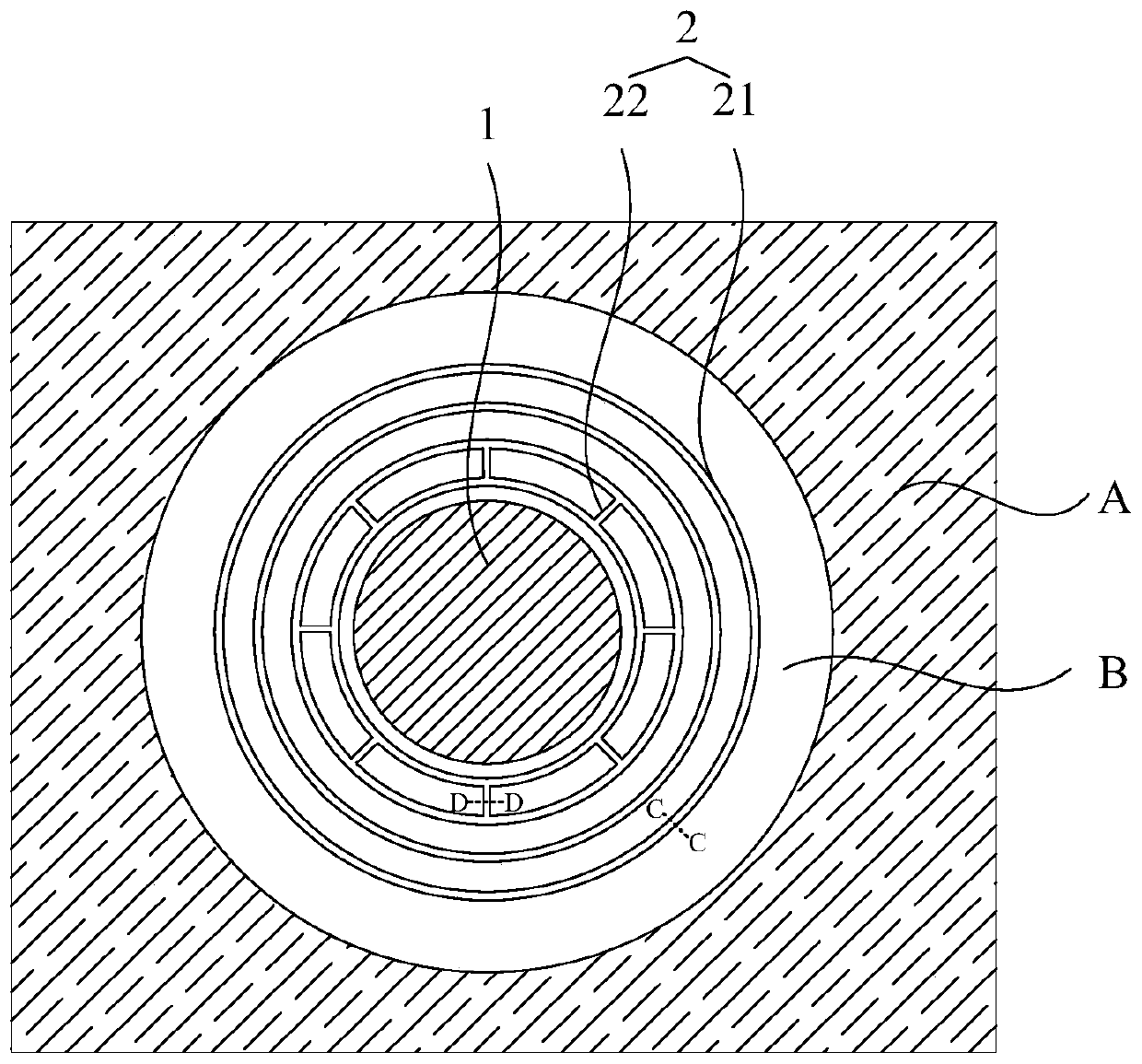

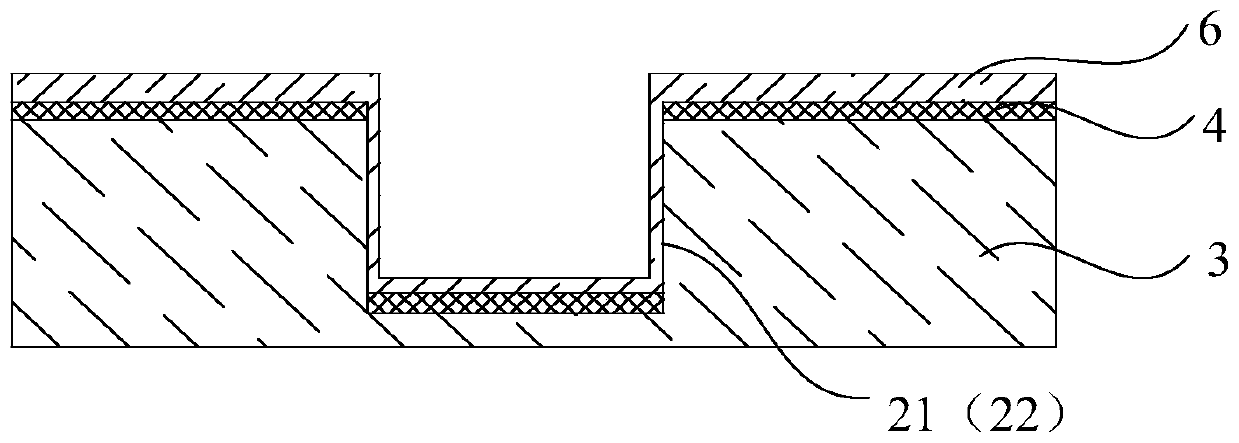

[0030] Currently, such as figure 1 As shown, for a display panel with a hole 01 in the display area A, the hole-digging process on the display panel will directly expose the vapor-deposited film on the entire surface, and external water vapor will enter through the hole and oxidize the vapor-deposited film. To prevent water vapor from entering, usually multiple ring-shaped trenches 02 are set around the external control, which can directly isolate the vapor deposition film naturally during the vapor deposition process to prevent water vapor from intruding. But like figure 1 As shown, when the vapor deposition film layer is not completely blocked at a certain part of an annular groove, water vapor will invade the oxidation vapor deposition film along the uninterrupted point 021. When there are uninterrupted at different positions of multiple annular grooves at the same time When it is clicked, water vapor will invade layer by layer along the direction parallel to the boundary of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com