Underwater trapezoidal fluid blocking Karman vortex street vibration power generation device

A vibration power generation and bluff body technology, which is applied to electromechanical devices, electrical components, etc., can solve the problems of insufficient sealing of power generation devices, unstable power source, and large loss of mechanical energy, and achieve resistance reduction of incoming flow and enhancement of vortex street periodic force. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

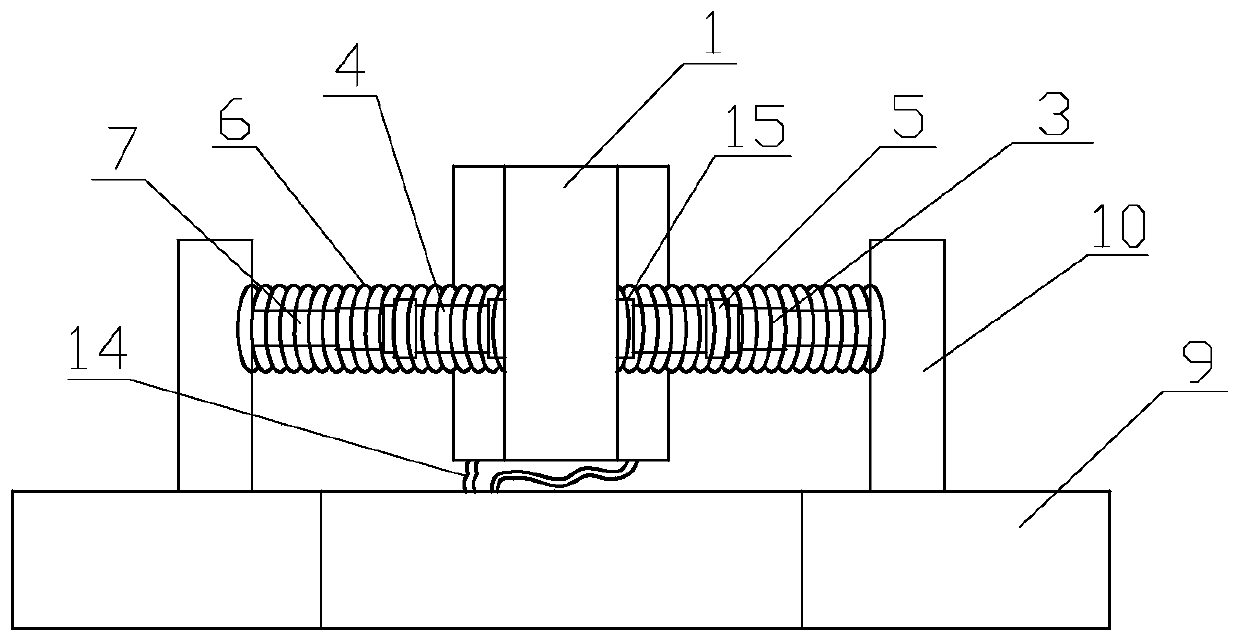

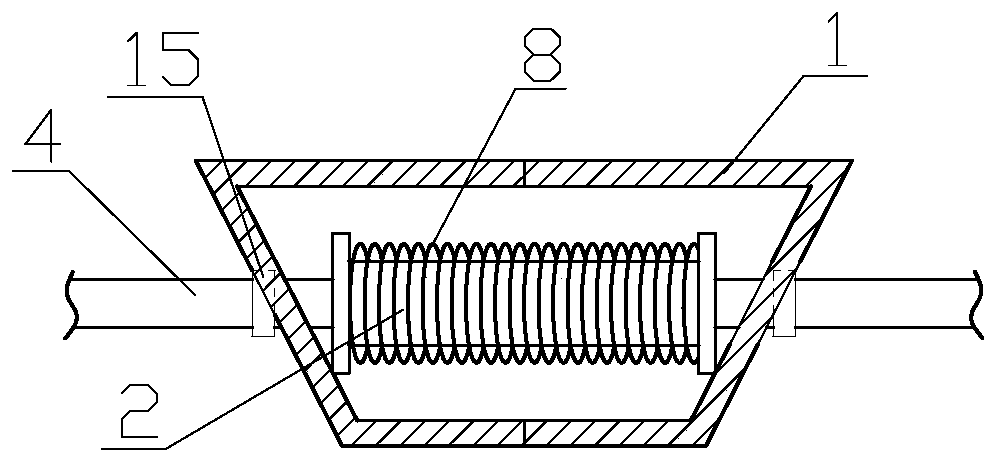

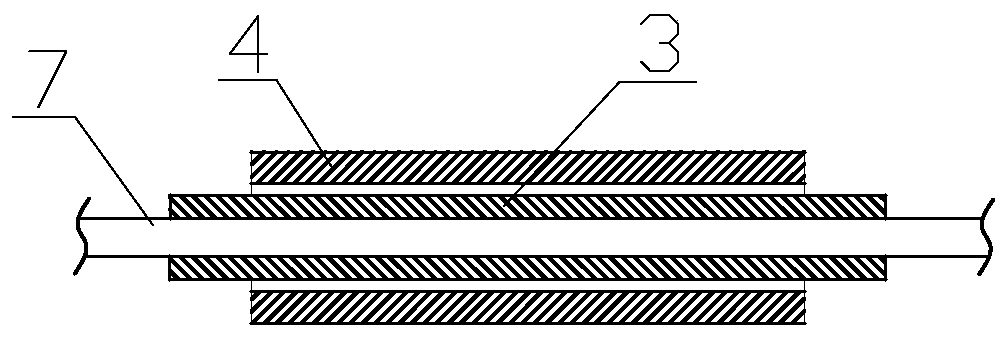

[0025] Such as Figure 1-3 As shown, an underwater trapezoidal bluff body Karman vortex street vibration power generation device includes a bluff body 1, a winding sleeve 2, a magnet sleeve 3, a fixed sleeve 4, a buffer spring 6, a cross bar 7 and a magnet sleeve, and the magnet The cover includes a first magnet cover 5 and a second magnet cover 15 . The bluff body 1 is a hollow structure, the magnet sleeve 3 is fixedly sleeved on the cross bar 7, the fixed sleeve 4 is slidably sleeved on the magnet sleeve 3, and the fixed sleeve 4 and the magnet sleeve 3 can slide relative to each other. The sleeve 4 penetrates the bluff body 1 and is sealed and fixedly connected with the side wall of the bluff body 1, so that the interior of the bluff body 1 forms a closed space, and the second magnet sleeve 15 is provided at the connection between the fixed sleeve 4 and the outer wall of the bluff body 1, The second magnet sleeve 15 is provided with a bar magnet 16 . The winding sleeve 2 ...

Embodiment 2

[0037] The difference from Example 1 is that, as Figure 6 As shown, the four corners of the bluff body 1 are rounded on a trapezoidal basis, and the rounded corners of the short side are larger than the rounded corners of the long side, and the long side of the bluff body 1 is an arc surface. The arc long surface and rounded corners are used to reduce the resistance of incoming flow, reduce the impact of seawater on the bluff body, and improve stability. Enhance the vortex induced force and improve the power generation efficiency. The specific side length of the bluff body 1 can be determined according to actual working conditions.

Embodiment 3

[0039] The difference from Embodiment 1 is that more than two cross bars 7 can be superimposed on the column 10 . Such as Figure 7 As shown, two crossbars 7 are superimposed on the column 10, and each crossbar 7 is provided with a bluff body 1, a winding sleeve 2, a magnet sleeve 3, a fixed sleeve 4, a first magnet sleeve 5, a second The magnet sleeve 15, the buffer spring 6, and the two bluff bodies 1 are connected to the rectifier 11 through wires 14, respectively. The buffer spring 6, the cross bar 7, the magnet sleeve 3, the first magnet sleeve 5, the second magnet sleeve 15 and the fixed sleeve 4 are detachable and replaceable as a whole unit, and the column can be extended to increase the cross bar according to the electricity demand of the object of use. 7, so as to superimpose multiple power generation units to increase power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com