A full metal seal pilot safety valve

A pilot-operated safety valve, all-metal technology, used in safety valves, valve devices, balance valves, etc., can solve the problems of limited high temperature resistance of non-metallic materials, inability to apply sealing specific pressure, and inability to meet market demand, etc. The effect of movement reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

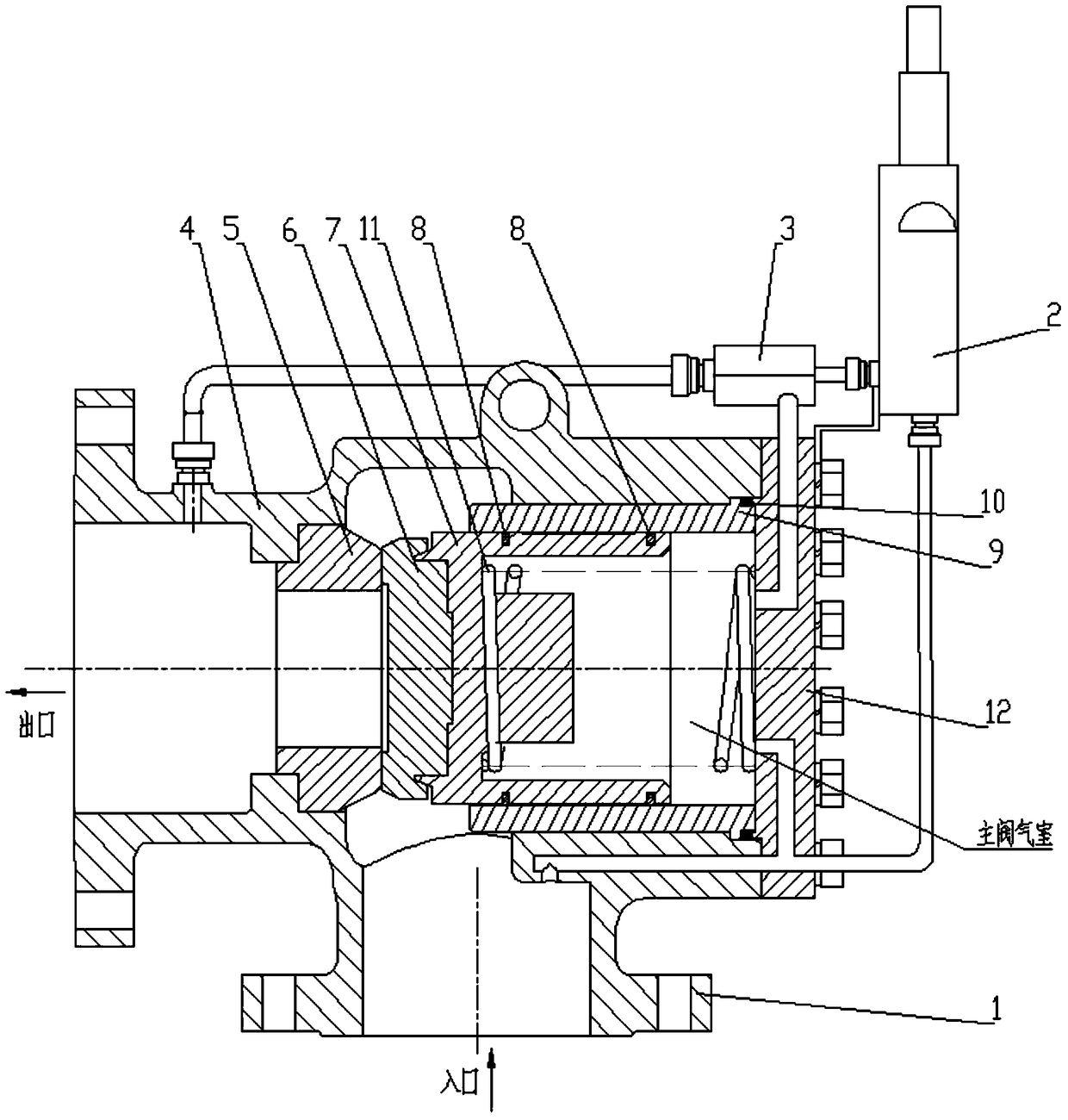

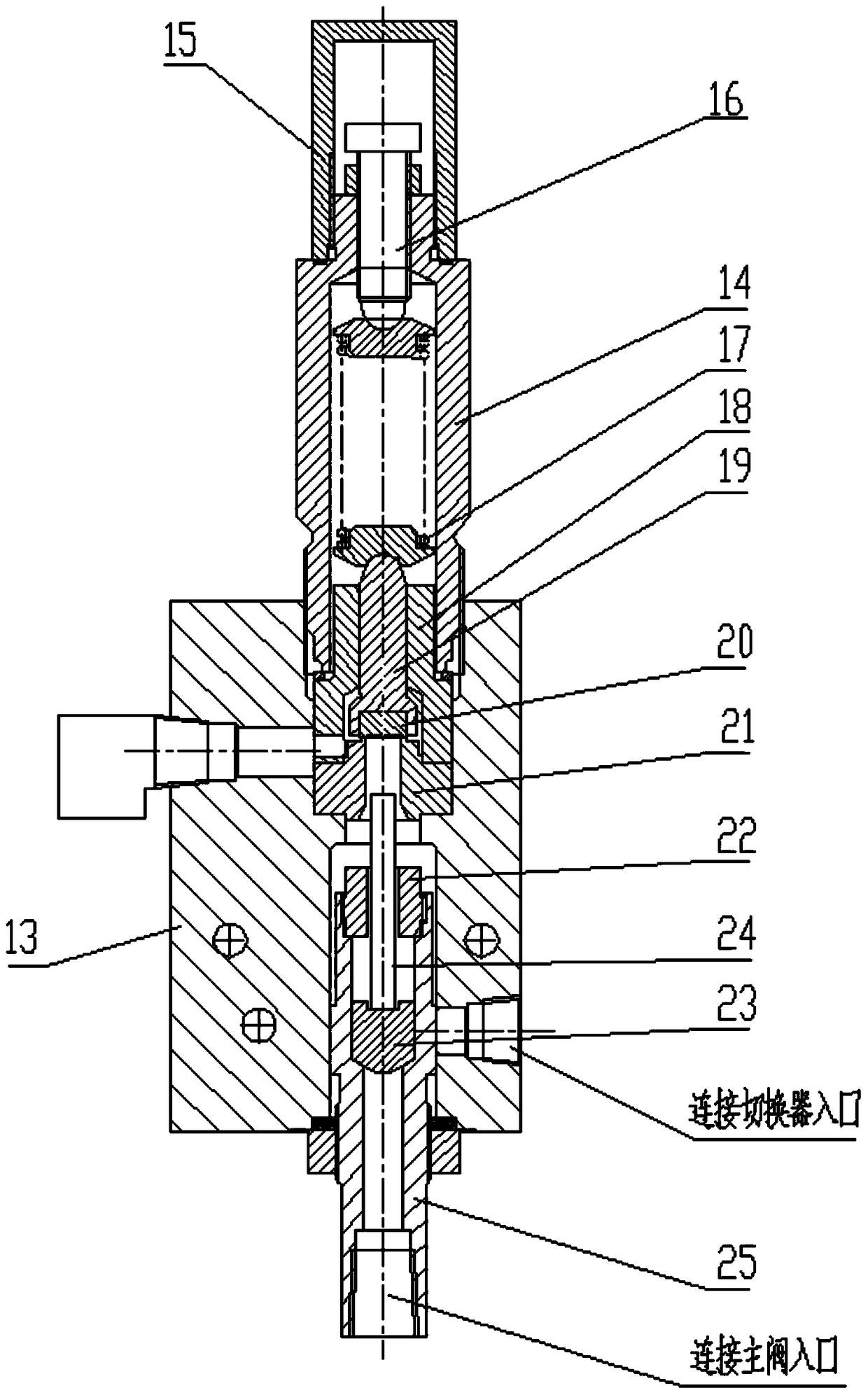

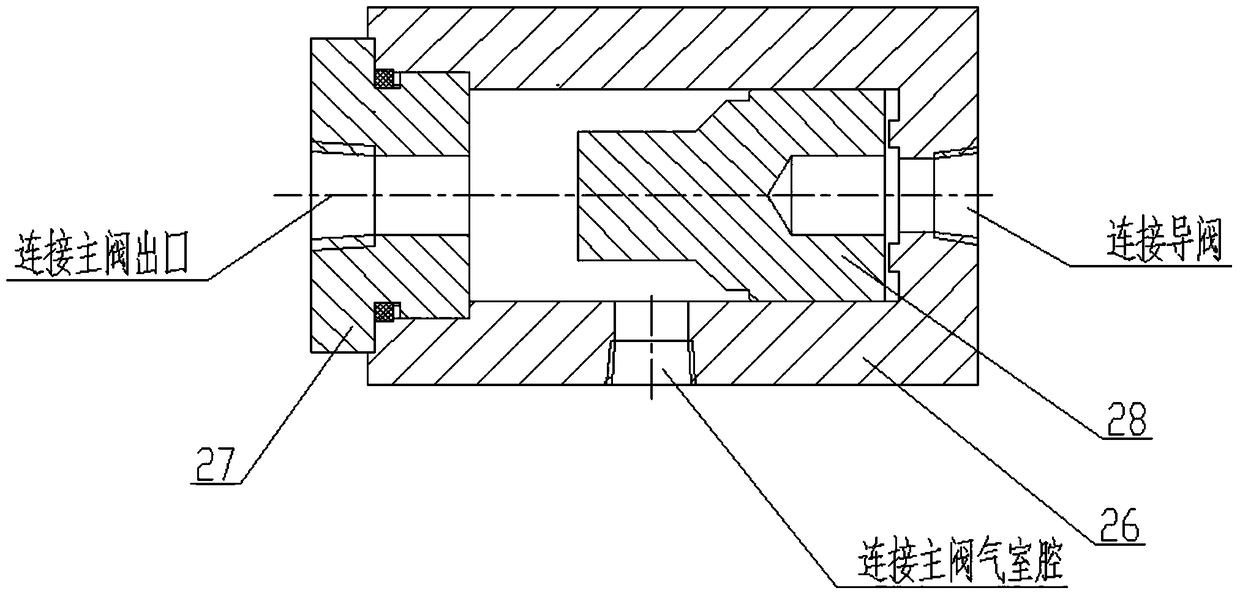

[0027] Such as figure 1 As shown, the full metal seal pilot safety valve is composed of main valve 1, pilot valve 2 and switcher 3. The pilot valve 2 is respectively connected with the inlet of the main valve and the inlet of the switch 3 through pressure pipes. The three passages on the switcher 3 are respectively connected with the inlet of the pilot valve, the cavity of the air chamber of the main valve and the outlet of the main valve by means of pressure pipes.

[0028] The main valve 1 is composed of the main valve body 4, the main valve seat 5, the main valve disc 6, the piston 7, the sealing ring 8, the main valve guide sleeve 9, the graphite pad 10, the main valve spring 11, and the cover plate 12.

[0029] The lower end of the main valve body 4 is an inlet, and one side is processed with an outlet, and both the inlet and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com