Proportional valve for controlling a gaseous medium

A technology for controlling gas and proportional valves, applied in the field of proportional valves, can solve problems such as valve seat wear, achieve the effects of improving sealing, reducing wear, and optimizing function modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

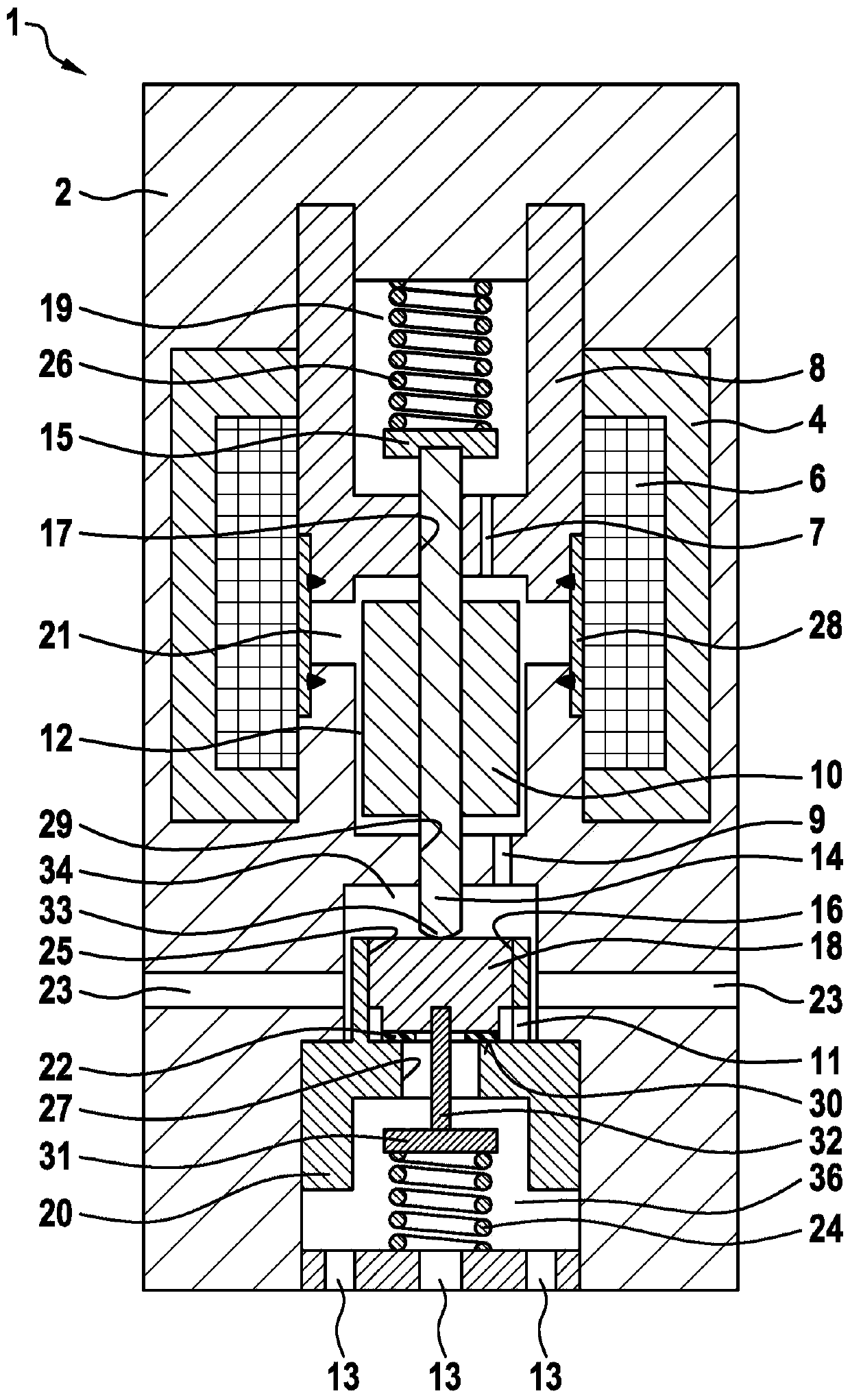

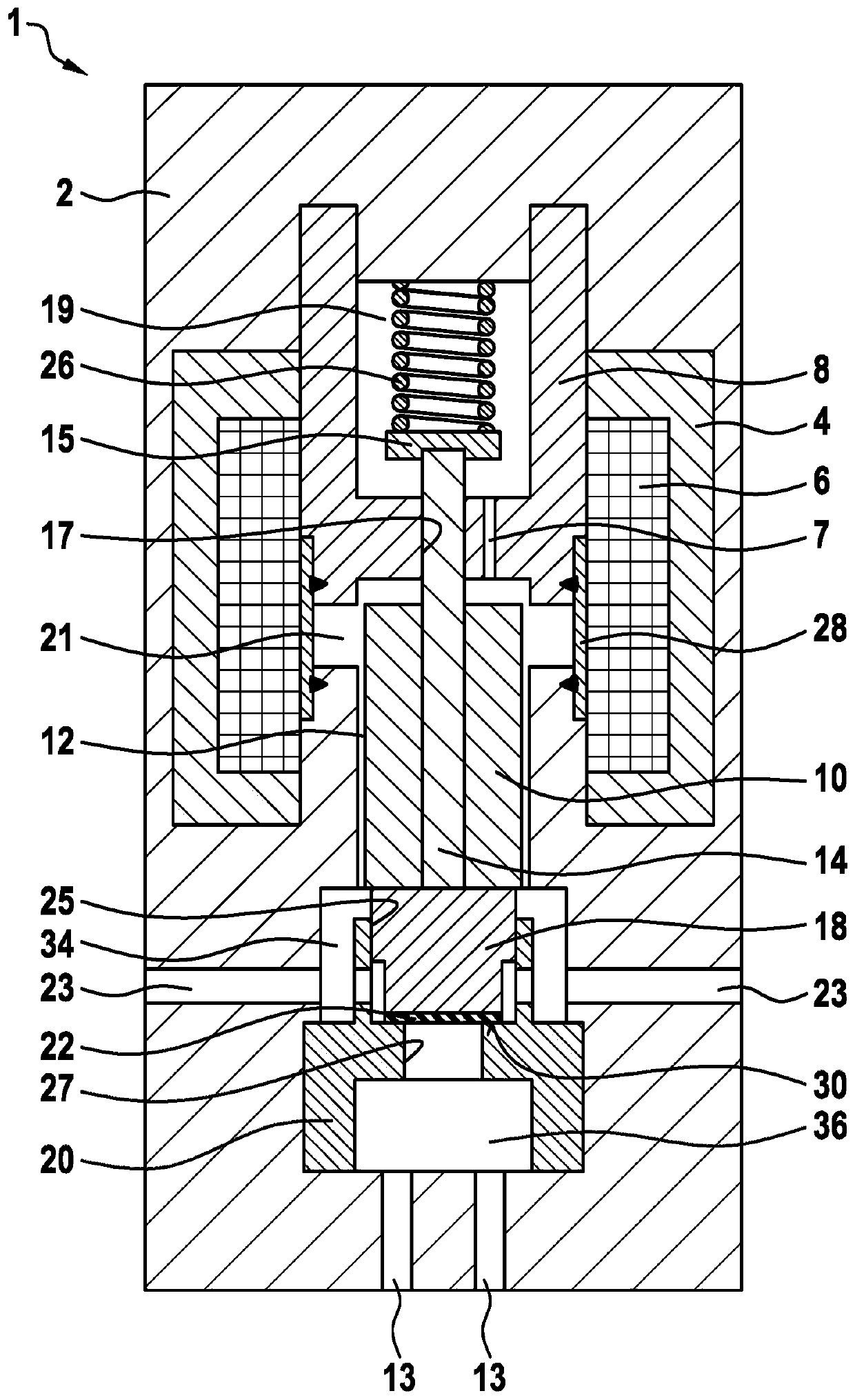

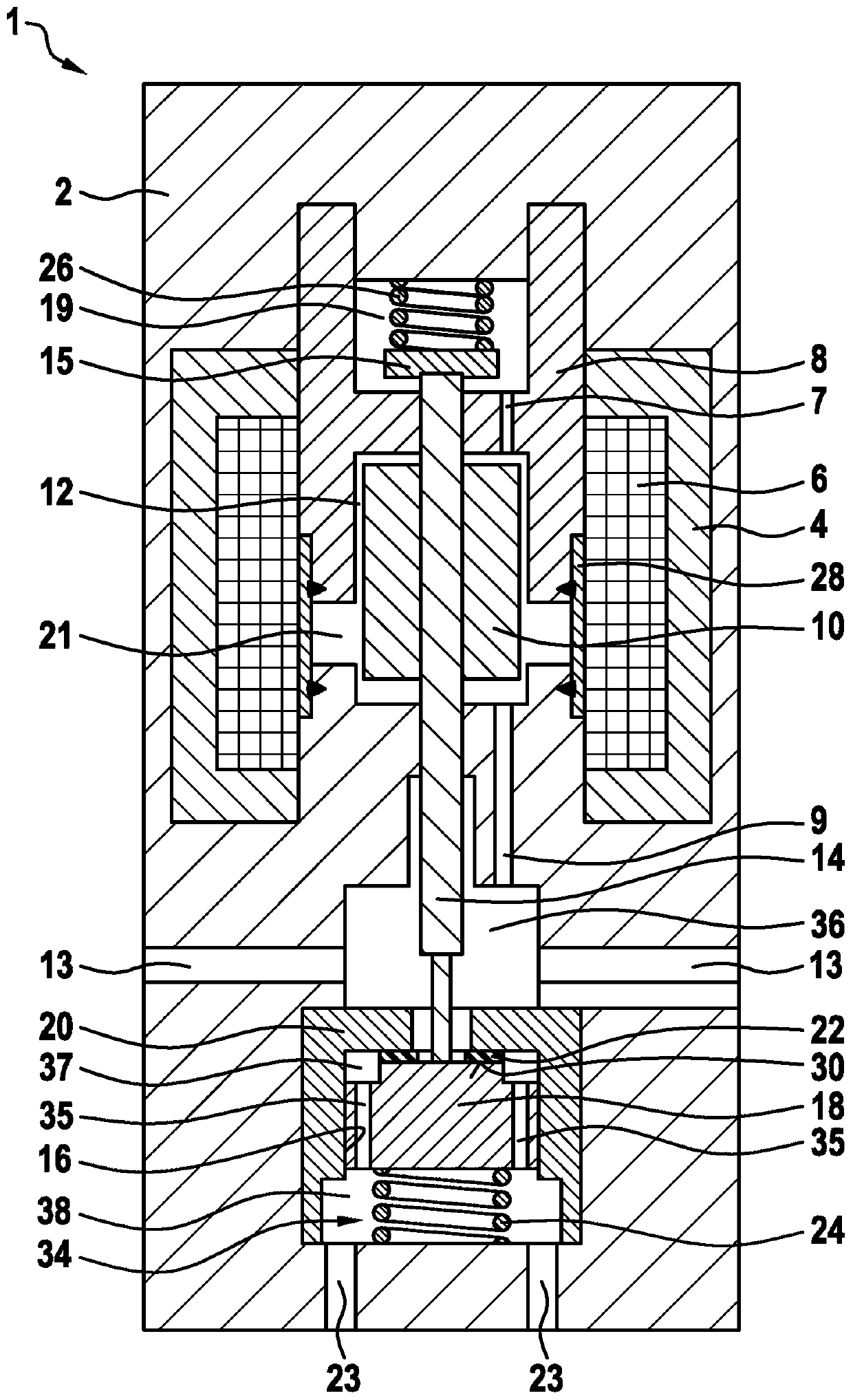

[0022] figure 1 A first exemplary embodiment of the proportional valve 1 according to the invention is shown in longitudinal section. The proportional valve 1 has a valve housing 2 in which an outer pole 4 , an inner pole 8 , a magnetic coil 6 and a nozzle body 20 are arranged. A first through-opening 17 is formed in the inner pole 8 , through which the first connecting element 14 protrudes, wherein the first connecting element 14 is axially guided in the first through-opening 17 . The first connecting element 14 is firmly connected to the solenoid armature 10 , wherein a magnetic air gap 12 is formed between the solenoid armature 10 and the valve housing 2 .

[0023] The inner pole 8 and the valve housing 2 delimit a spring chamber 19 in which the first spring 26 is arranged. The first spring 26 is supported on the one hand on the valve housing 2 and on the other hand on the disk-shaped end 15 of the first connecting element 14 and acts on said disk-shaped end in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com