Agricultural residual film recycling machine

A recycling machine and residual film technology, which is applied in the field of agricultural machinery, can solve the problems of low mechanical operation efficiency, high transportation cost, and high recycling cost, and achieve the effect of expanding the scale of recycling, changing the agricultural ecological environment, and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

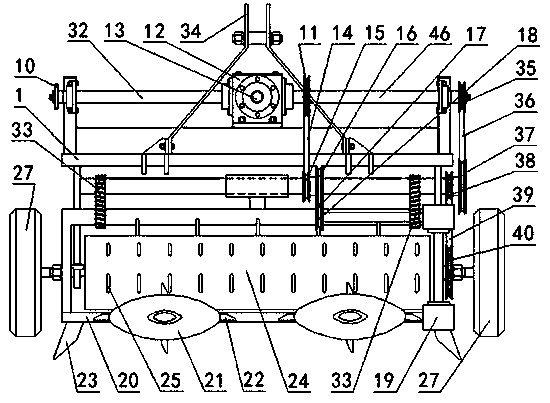

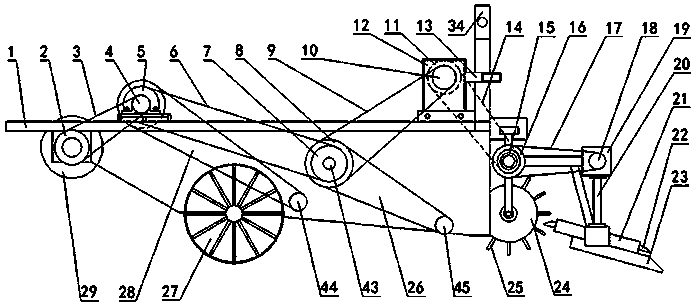

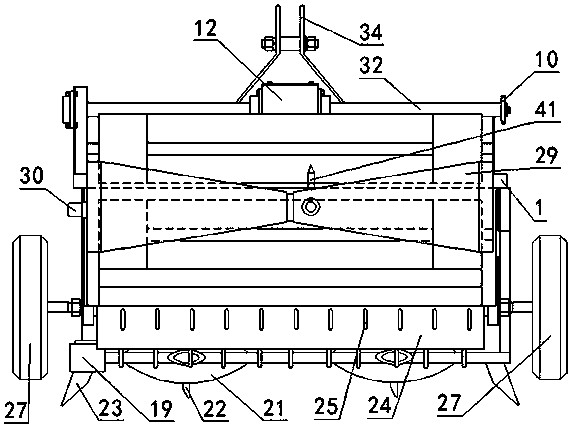

Embodiment 1

[0012] Example 1 as Figure 1-Figure 5As shown, an agricultural residual film recycling machine has the following structure: the upper part of the frame (1) is a quadrilateral frame, with side plates welded on both sides, and the film rolling device (29) is arranged on the frame from left to right, and the conveyor B (28), conveyor A (26), reducer (12), traction frame (34), traveling wheels (27) are set between the two side plates through the transmission shaft, and the film rolling device (29) is two A hollow truncated cone, with two small ends facing each other, a film roll handle (30) is provided at one end of the film rolling device (29), a sprocket A (2) is fixed at the other end of the film device (29), and a film roll rod (41) is arranged in the middle. ), a conveying shaft A (42) of the conveyor B (28) is set on the upper part of the frame (1), and one end of the conveying shaft A (42) is fixed with a sprocket B (4) and a sprocket C (5), the other conveying shaft B (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com