Rapid preparation and application of mba-bridged cyclodextrin-functionalized chiral monolithic columns

A cyclodextrin and monolithic column technology, applied in the field of analytical chemistry, can solve the problems of cumbersome preparation process, no application of bridged cyclodextrins, long time consumption, etc., and achieves simple preparation process, improved chiral separation performance, and improved retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

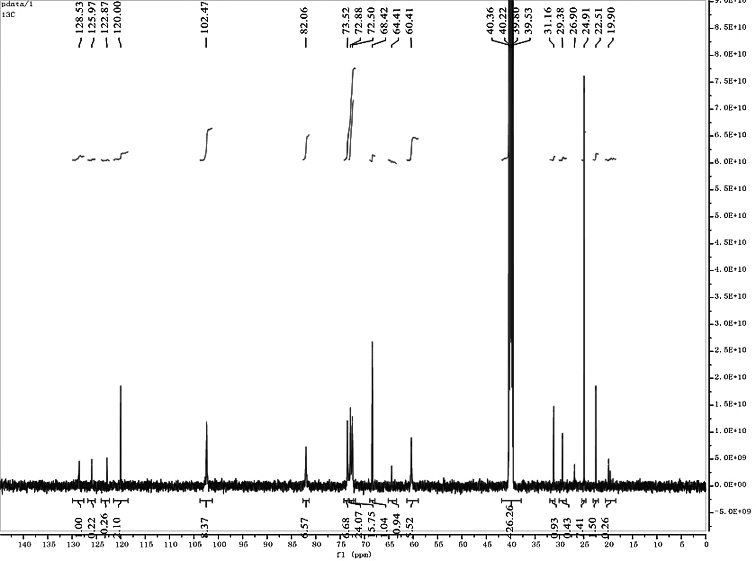

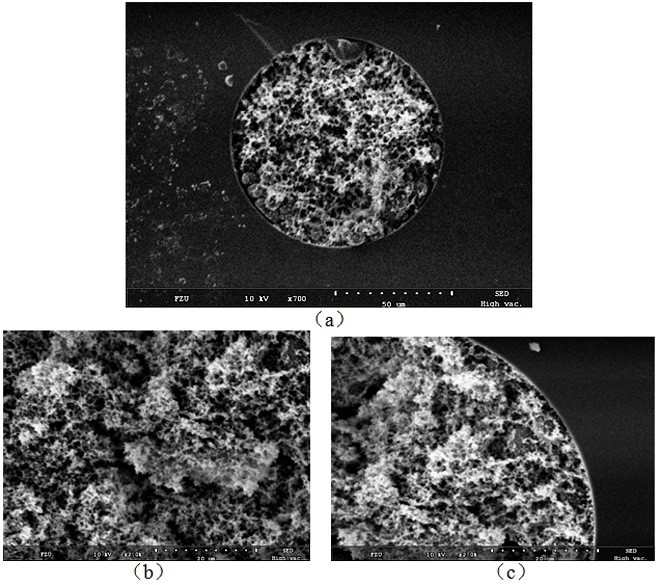

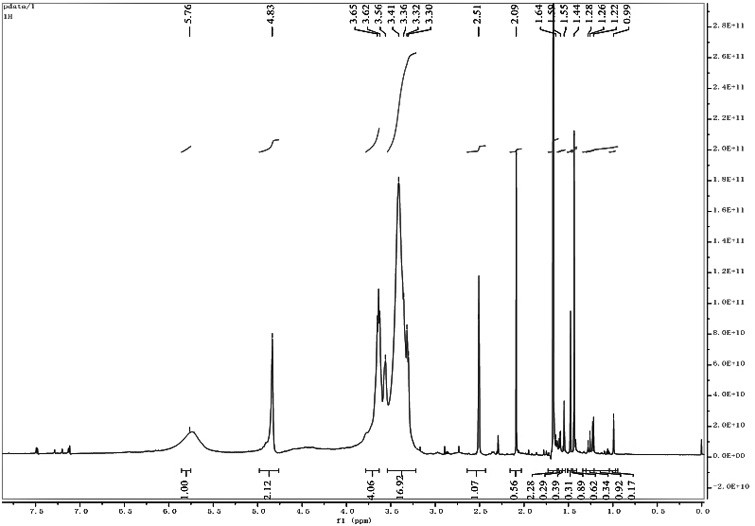

[0025] Example 1 The preparation method of MBA-bridged cyclodextrin functionalized chiral monolithic column, the specific steps are:

[0026] (1) Wash the fused silica capillary with 0.1 mol / L HCl solution for 30 min, double distilled water for 30 min, 0.1 mol / L NaOH solution for 4 h, double distilled water for 30 min, methanol for 30 min, Then dry with nitrogen at room temperature and 0.4 MPa for 30 min; in order to introduce the amino group into the inner surface of the capillary to bond the substrate, then fill the capillary with a methanol solution of aminopropyltrimethoxysilane with a volume concentration of 50%, and use Seal the capillary with silicone rubber, heat the capillary in a water bath at 60 °C for 24 h, rinse the capillary with methanol for 30 min, and then dry it with nitrogen at 70 °C and 0.4 MPa for 3 h to obtain a pretreated quartz capillary. for further use;

[0027](2) Accurately weigh 1 mg MBA, 14.93 mg SH-β-CD, 1 mg AIBA and 200 mg deionized water into...

Embodiment 2

[0030] Replace the amount of deionized water added in step (2) of Example 1 with 250 mg, the amount of urea added in step (3) with 250 mg urea, and the amount of formaldehyde solution added with 500 mg. Other steps are as in Example 1. Column A can be obtained.

Embodiment 3

[0032] Replace the amount of deionized water added in step (2) of Example 1 with 225 mg, the amount of urea added in step (3) with 225 mg urea, and the amount of formaldehyde solution added with 450 mg. Other steps are as in Example 1. Column B can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com