Auxiliary platform for processing mechanical component

A technology of mechanical parts and auxiliary platforms, applied in the direction of metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of poor flexibility, inconvenient use and operation, and single positioning point, so as to achieve flexible use and satisfy clamping The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

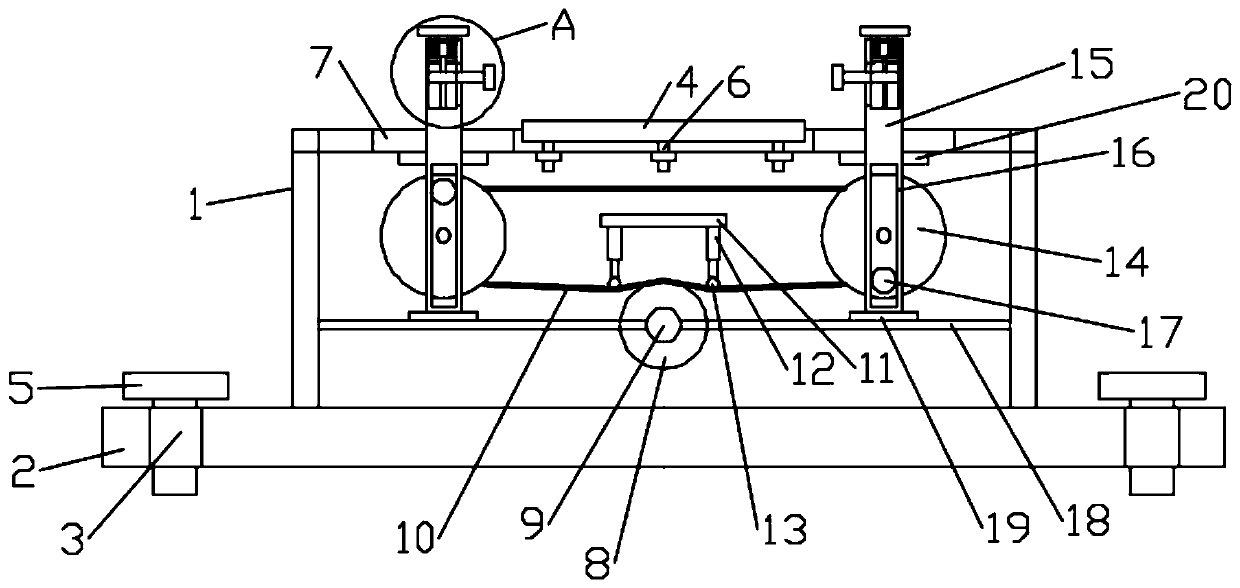

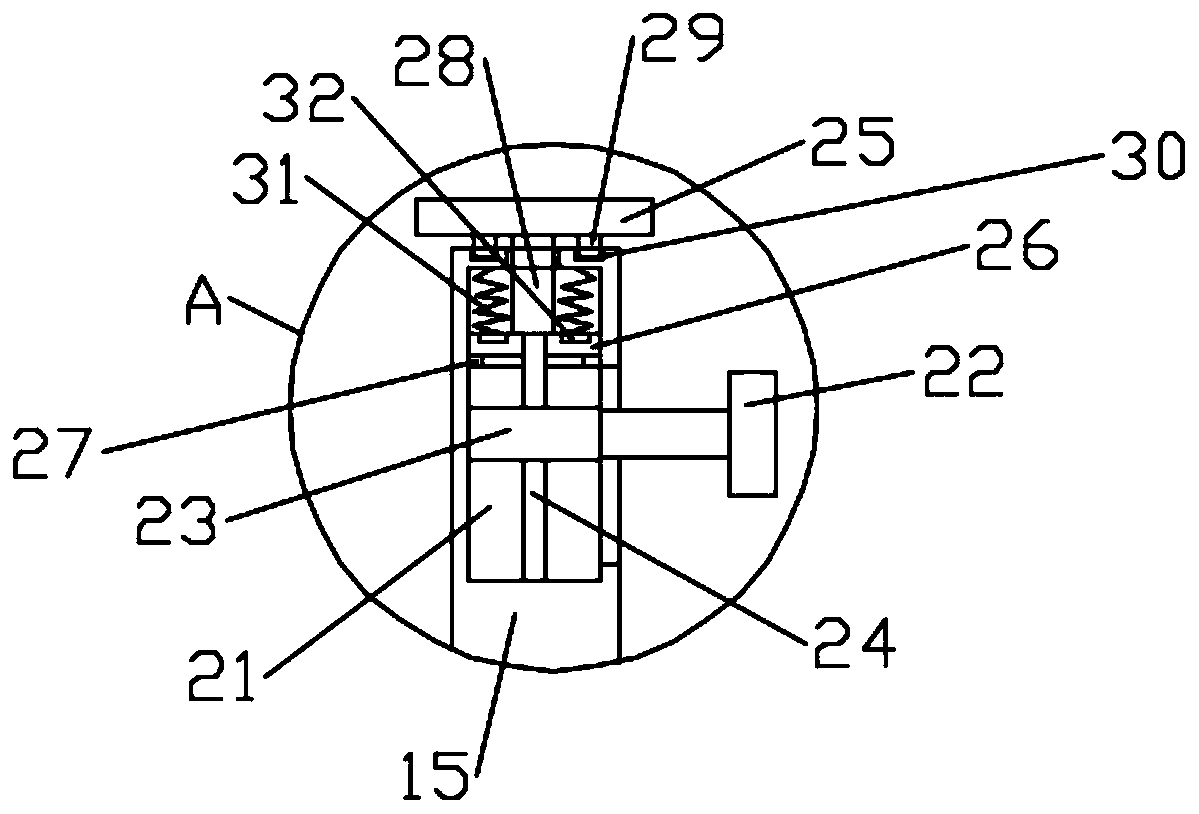

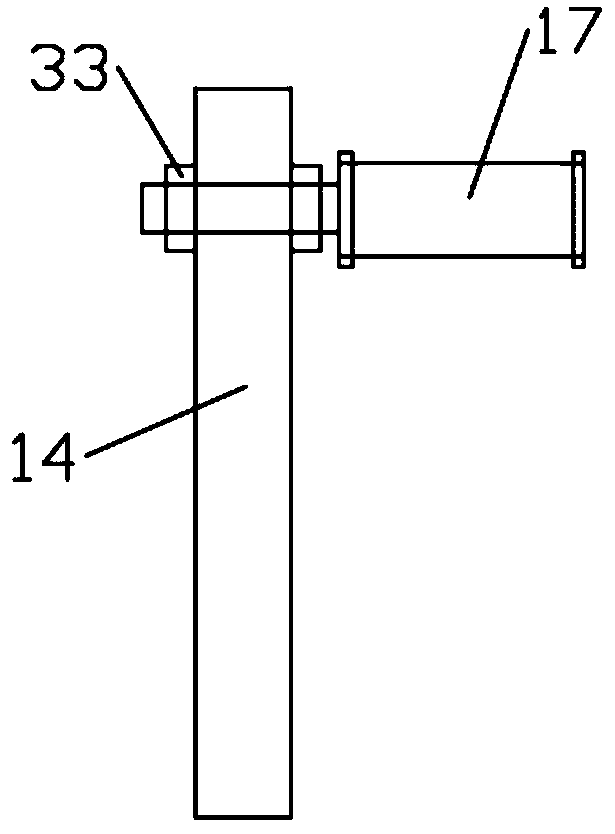

[0029] like Figure 1-2 As shown, in the embodiment provided by the present invention, an auxiliary platform for processing mechanical parts includes a support box seat 1 fixedly installed on the support base plate 2, and the inner cavities on both sides of the support box seat 1 are rotated. There is a driven sprocket 14, and the transmission chain 10 is connected between the two driven sprockets 14. A drive motor 9 for driving the two driven sprockets 14 to rotate synchronously is also installed in the support box seat 1; The end faces of the driven sprockets 14 are all detachably equipped with guide columns 17; the upper surface of the middle part of the top plate of the support box seat 1 is fixedly installed with a positioning mold 4 through the second mounting bolts 6; Both sides of the top plate of the box base 1 are provided with adjustment columns 15 for sliding, the bottoms of the two adjustment columns 15 extend into the support box base 1, and the adjustment column...

Embodiment 2

[0038] like figure 1 As shown, the difference from Embodiment 1 is that in the embodiment provided by the present invention, the end of the support base plate 2 is fixedly installed with a mounting screw sleeve 3, and the mounting screw sleeve 3 is threaded through a threaded connection. The first mounting bolt 5 realizes the installation of the auxiliary platform on the processing machine through the mutual cooperation of the mounting nut 3 and the first mounting bolt 5 .

[0039] In order to achieve the effect that the drive motor 9 drives the two driven sprockets 14 to rotate synchronously, in the embodiment provided by the present invention, a support guide rail 18 is fixedly installed in the support box seat 1, and the drive motor 9 is fixedly installed on the On the guide column 17, the output shaft of the driving motor 9 is installed with the drive sprocket 8, and a section of the transmission chain 10 is engaged with the drive sprocket 8, so the power supply and start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com