Mold opening and closing sequence control mechanism and three-plate mold

A sequence control, mold opening and closing technology, applied in the field of molds, can solve problems such as difficulty in realization and control, and uncontrollability of damping pins, and achieve the effects of simple structure, reliable control effect, and improved adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

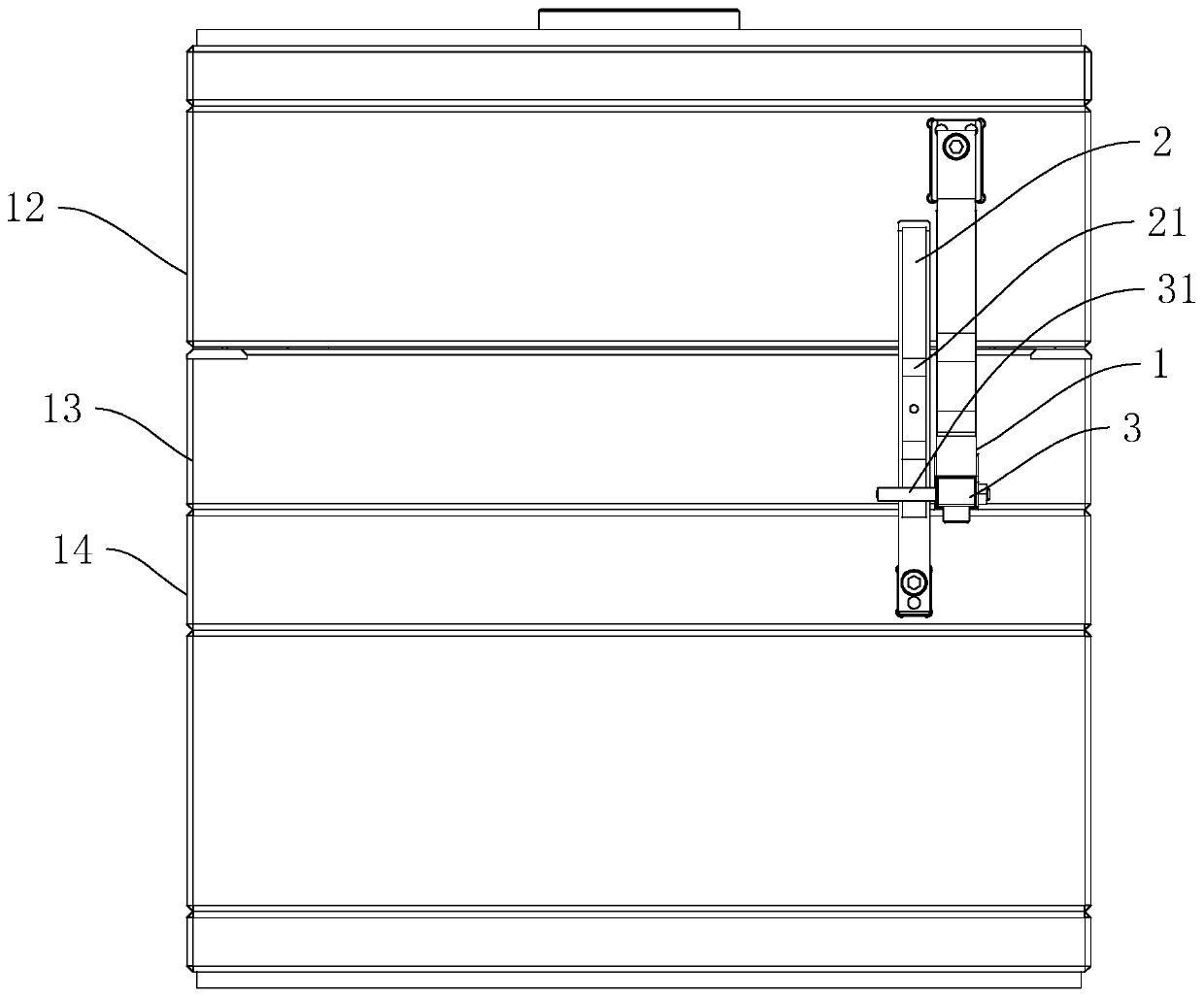

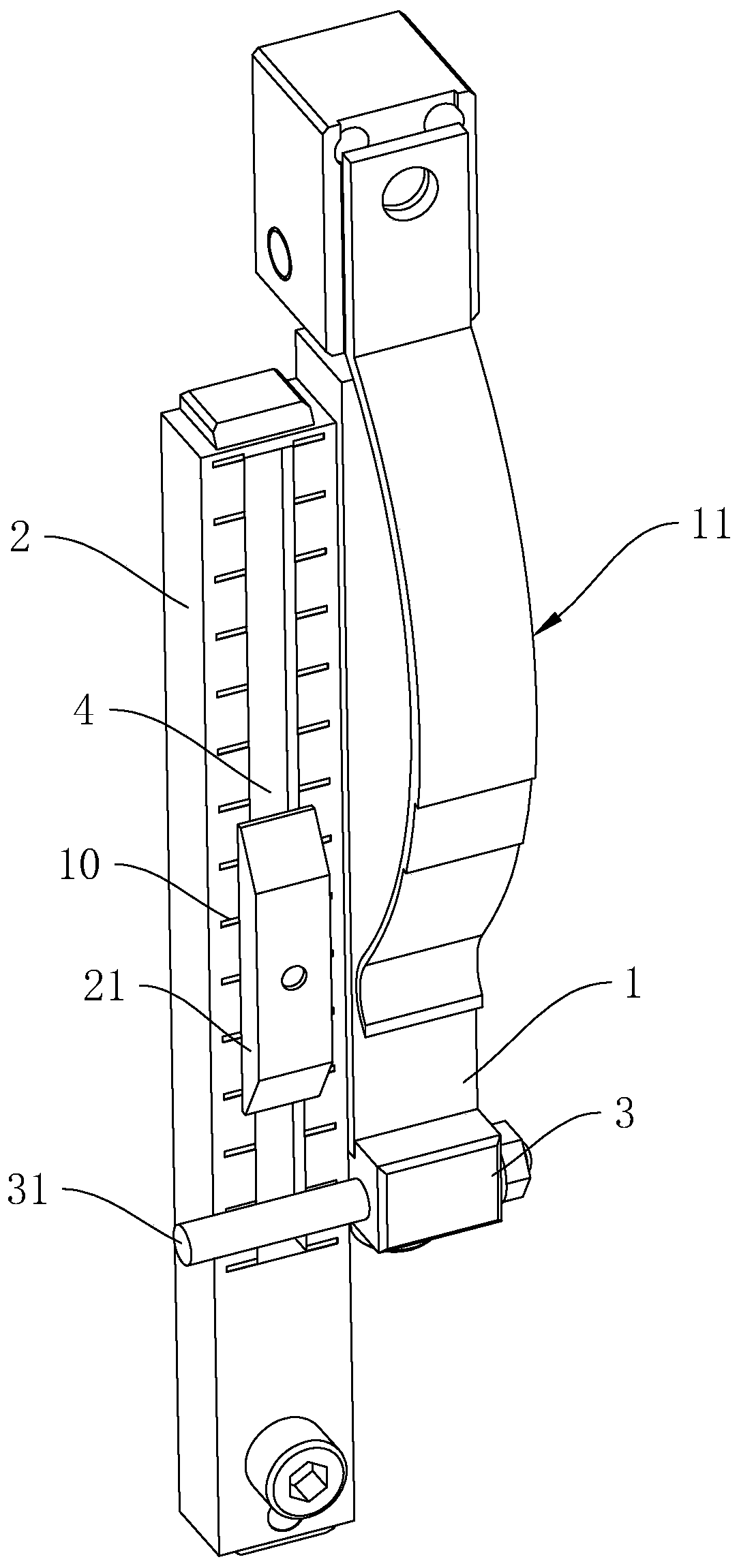

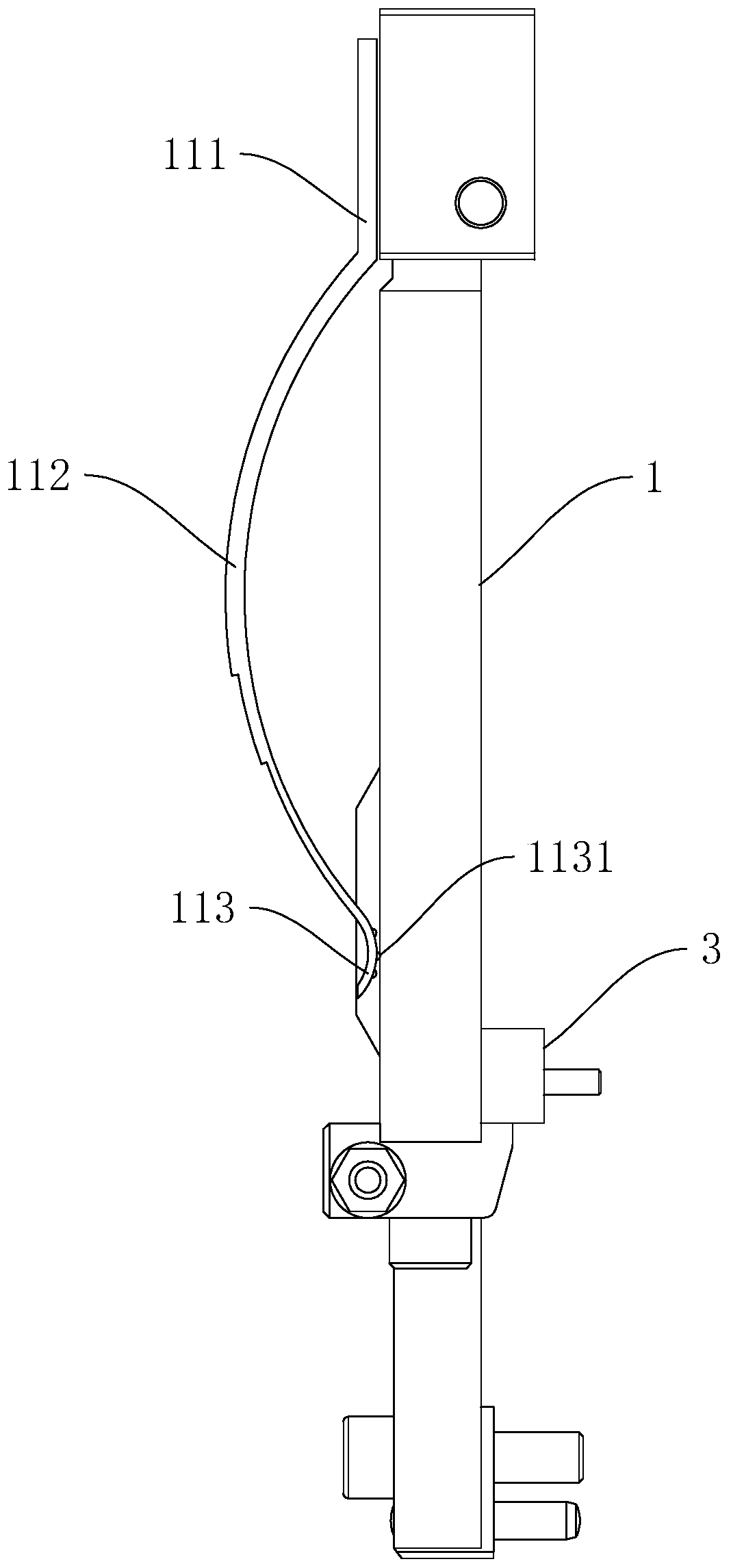

[0041] Embodiment 1, a mold opening and closing sequence control mechanism, such as figure 1 and figure 2 As shown, it includes a mold opening and closing control panel 1 and a mold opening and closing limiting plate 2. One end of the opening and closing mold control panel 1 is hinged on the outer surface of the upper template 12, and the other end of the opening and closing mold control panel 1 is connected with a locking Part 3, the locking part 3 is an L-shaped hook body, and a groove corresponding to the hook body is opened on the middle template 13 (not shown in the figure). When the hook body is inserted into the groove, the upper template 12 and the middle template can be realized. Locking of template 13. In addition, one end of the opening and closing mold limiting plate 2 is fixed on the outer surface of the lower template 14, the other end is arranged in parallel with the opening and closing mold control panel 1, and a protrusion is installed on the opening and clo...

Embodiment 2

[0051] Embodiment two, a kind of three plate mould, such as Figure 5 As shown, it includes an upper template 12, a middle template 13, a lower template 14 and two mold opening and closing sequence control mechanisms. The mold opening and closing sequence control mechanism adopts the mold opening and closing sequence control mechanism in Embodiment 1, and its specific structure is here No more details. Therefore, through the above-mentioned mold opening and closing sequence control mechanism, the mold opening and closing sequence between the templates in the three-plate mold can be accurately controlled, and the connection mode is stable, which can better meet the needs of processed products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com