Vehicle side tipping control device

A control device and vehicle-side technology, which is applied to vehicle components, transportation and packaging, elastic suspension, etc., can solve the problems of high cost, complex control system, and inability to balance the steering flexibility and comfort of the anti-roll device, and achieve Good anti-rolling, simple control system, good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

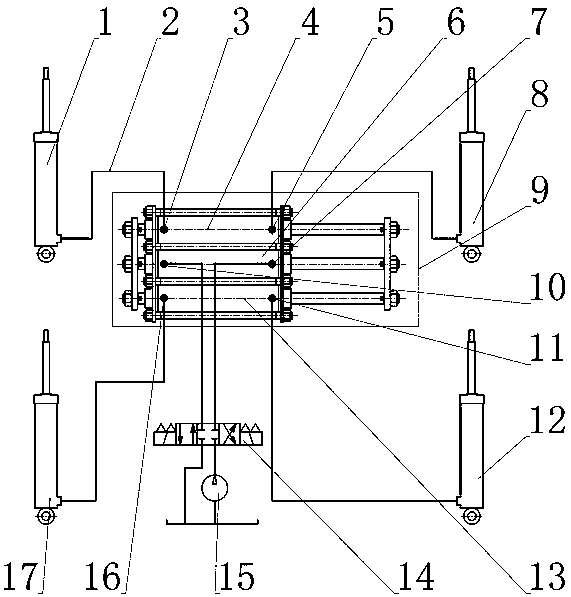

[0038] Preferred solution: roll control device composed of triple double-rod hydraulic cylinders

[0039] The roll control device includes: front double-rod hydraulic cylinder, rear double-rod hydraulic cylinder, displacement execution double-rod hydraulic cylinder, hydraulic source, three-position four-way solenoid valve, lateral acceleration sensor, controller, displacement sensor, etc. .

[0040] Such as figure 1 Shown: The front double-rod hydraulic cylinder (4), the rear double-rod hydraulic cylinder (13) and the actuator (6) (displacement execution double-rod hydraulic cylinder) form a triple-linkage hydraulic cylinder (9); the displacement sensor measures The displacement value of the piston of the double-rod hydraulic cylinder; the displacement execution of the double-rod hydraulic cylinder (6) is provided by the hydraulic pump (15) with a hydraulic source, and its action is controlled by the three-position four-way valve (14), driving the three-linkage hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com