Steel ingot transfer trolley

A trolley and steel ingot technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of lack of fixtures, accelerated aging, and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

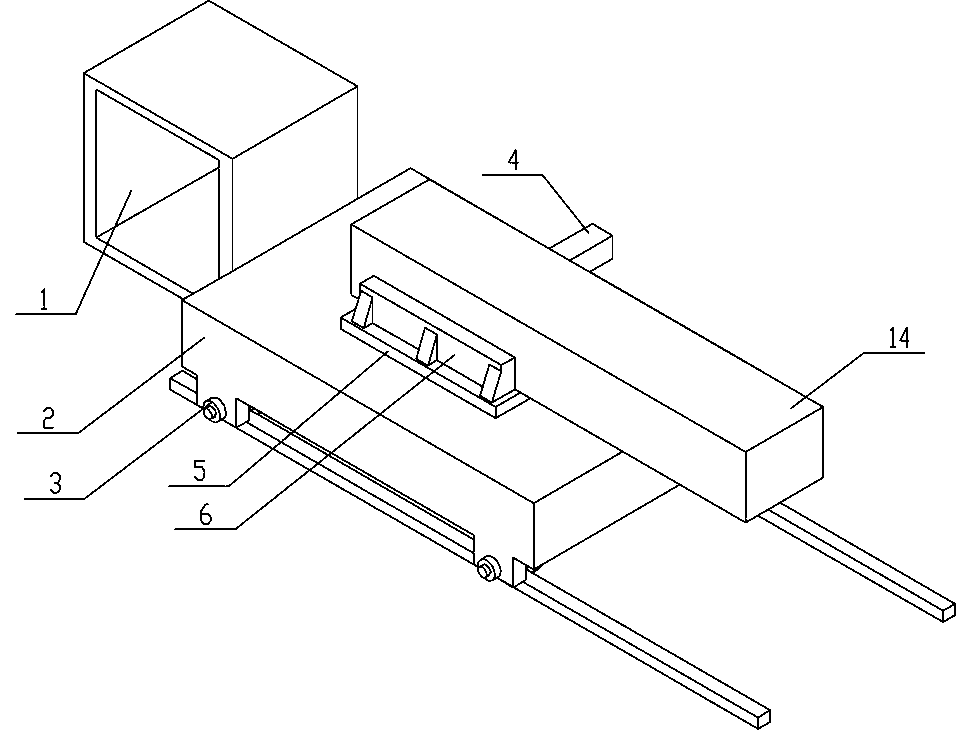

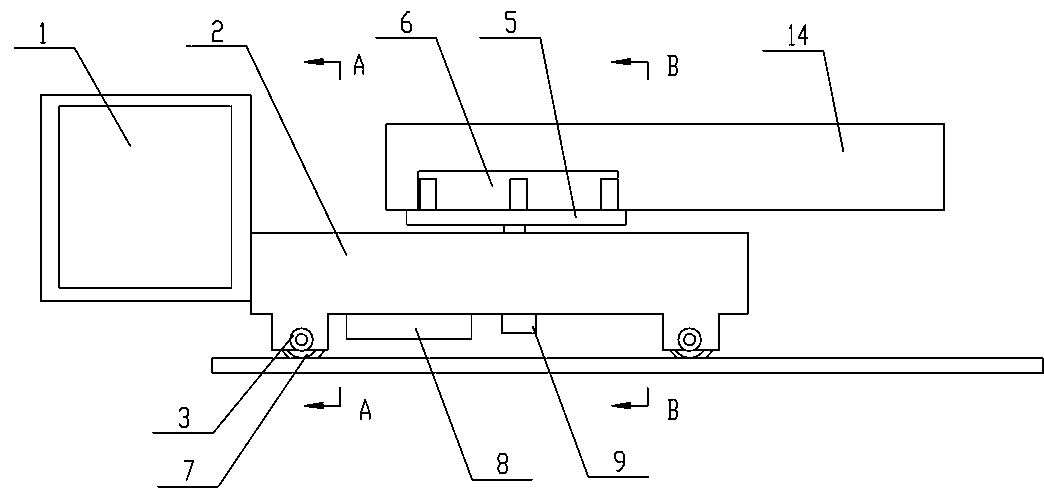

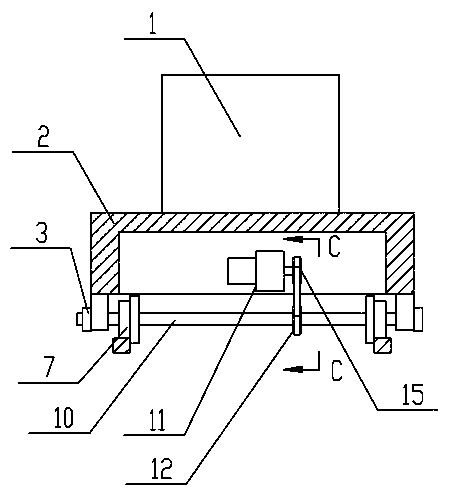

[0016] see Figure 1-6 , the present embodiment comprises vehicle frame 2, and vehicle frame 2 bottom is equipped with two wheel axles 10 through bearing 3, and each wheel axle 10 two ends are respectively equipped with a wheel 7, and vehicle frame 2 top is provided with a through hole, through hole A set of rotary driving device 9 is installed on the bottom surface of vehicle frame 2, the output shaft of rotary driving device 9 passes through the through hole and a horizontal rectangular bottom plate 5 is installed on the top, and a baffle plate 6 is fixedly installed on one side above the rectangular bottom plate 5. , the other side is equipped with an oil cylinder 4, the piston rod of the oil cylinder 4 is perpendicular to the baffle plate 6, and a movable plate 13 is installed at the end of the piston rod; a transmission wheel 12 is housed on one of the two wheel axles 10, and the vehicle Frame 2 bottom is positioned at driving wheel 12 one side and translation driving dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap