A flexible object stacking method and storage medium

A flexible object, laser technology, applied in the direction of lifting devices, etc., can solve the problems of unfavorable AGV promotion and application, reduce the transportation efficiency of flexible objects, cannot realize fully automated handling and delivery of goods, etc., to improve stacking efficiency, and the detection method is simple and direct. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below according to accompanying drawing, further illustrate technical scheme of the present invention:

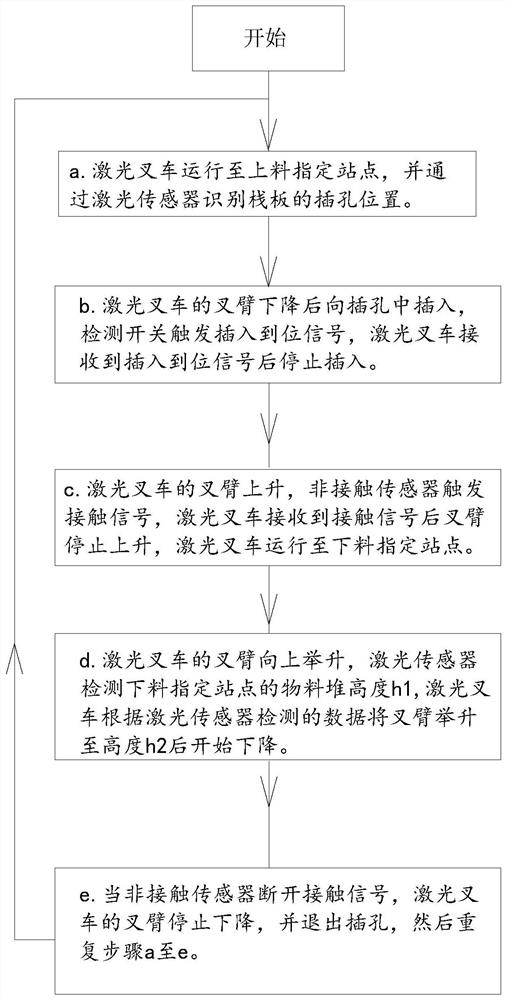

[0036] see figure 1 As shown, the present invention discloses a method for stacking flexible objects, which includes the following steps:

[0037] a. The laser forklift runs to the designated station for loading materials, and recognizes the jack position of the pallet through the laser sensor; b. The fork arm of the laser forklift is lowered and inserted into the jack, and the detection switch recognizes the insertion in place signal, and the laser forklift receives the insertion in place signal Stop the insertion after the signal; c. The fork arm of the laser forklift rises, and the contact signal is triggered by the non-contact sensor. After the laser forklift receives the contact signal, the fork arm stops rising, and the laser forklift runs to the designated station for unloading; d. The fork arm of the laser forklift Lifting up, the laser sensor detects the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com