Super-long glass multi-unit synchronous stacking device and control system thereof

A stacking device and multi-unit technology, which is applied in the field of ultra-long glass multi-unit synchronous stacking device and its control system, can solve problems such as unsuitable ultra-long glass stacking operations, unable to meet production needs, and affect work efficiency. Achieve the effect of improving the transshipment effect, reducing the occupied space and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in connection with the embodiment of the present invention, and will be described in connection with the embodiment of the present invention. Embodiments, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained without creative labor are not made in the premise of creative labor.

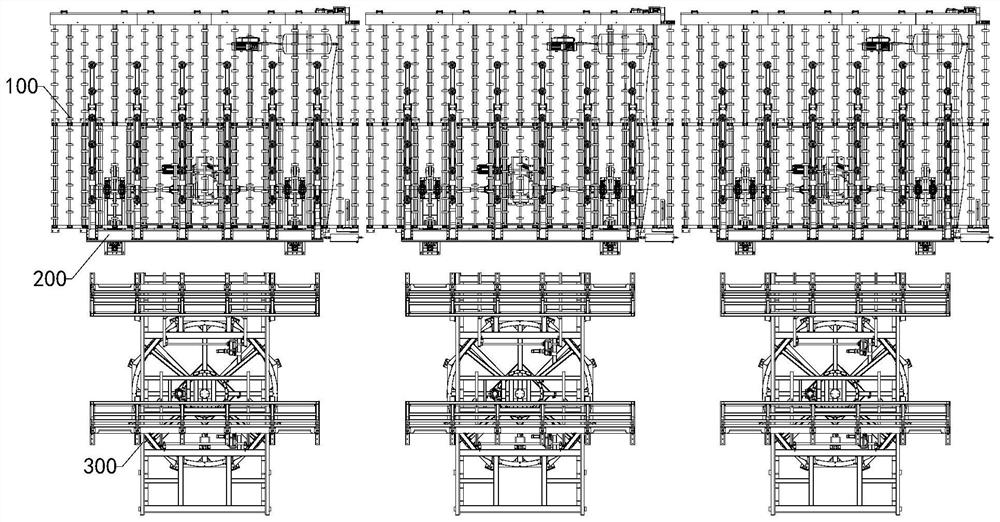

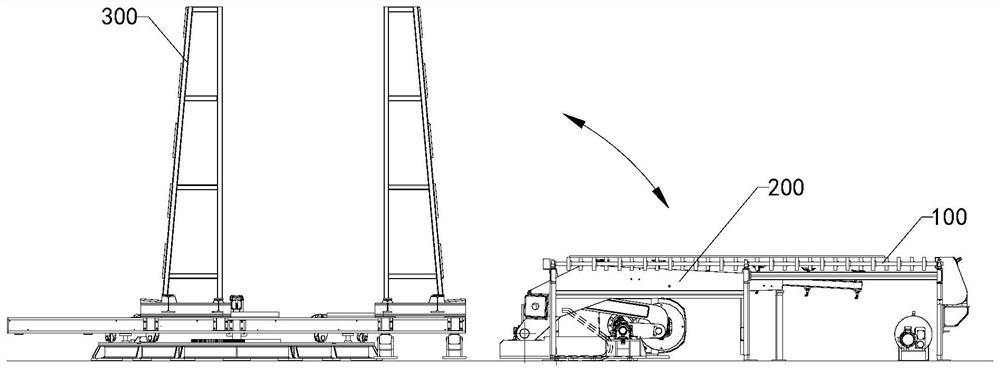

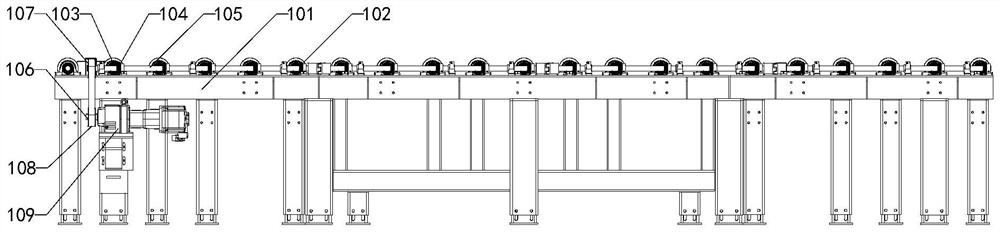

[0041] refer to figure 1 and figure 2 A synchronous multi-unit long glass stacking apparatus, comprising: a conveying unit 100, at least one lower sheet unit 200, a stacking unit 300, PLC controller, determines the length of the module, the module stack to make way, blowing detection module; the number sheet unit 200 is set according to the length of the glass production line, for example, to three lower sheet unit 200 as an example of the present embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com