A magnetic wrapping wire drawing machine that is easy to combine and assemble

A combined assembly and winding wire technology, applied in the field of magnetic winding wires, can solve the problems of inconvenient magnetic ring clamping, cumbersome operation process, structural combination and fixing, etc., and achieve the effect of convenient structural combination, simple winding operation, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

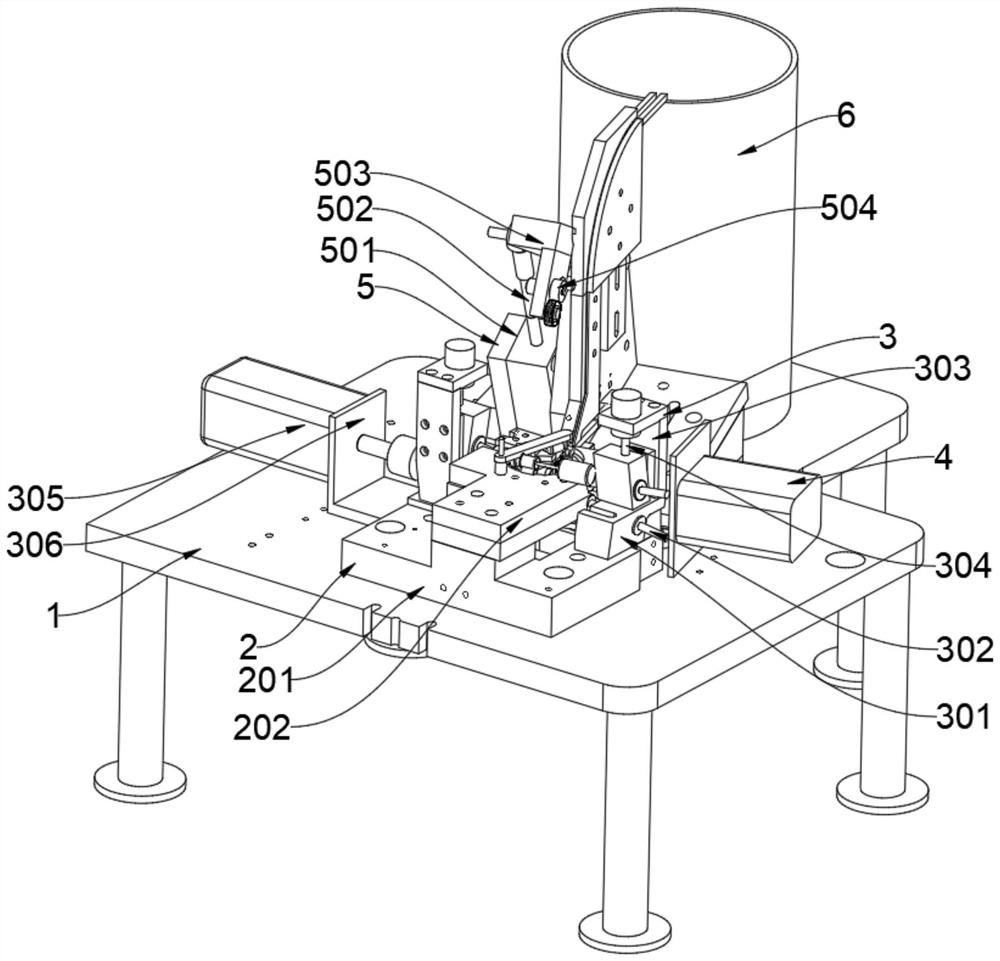

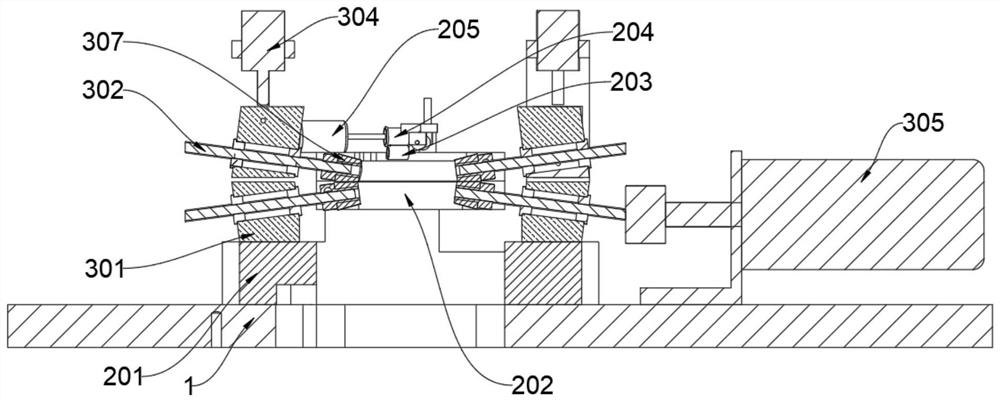

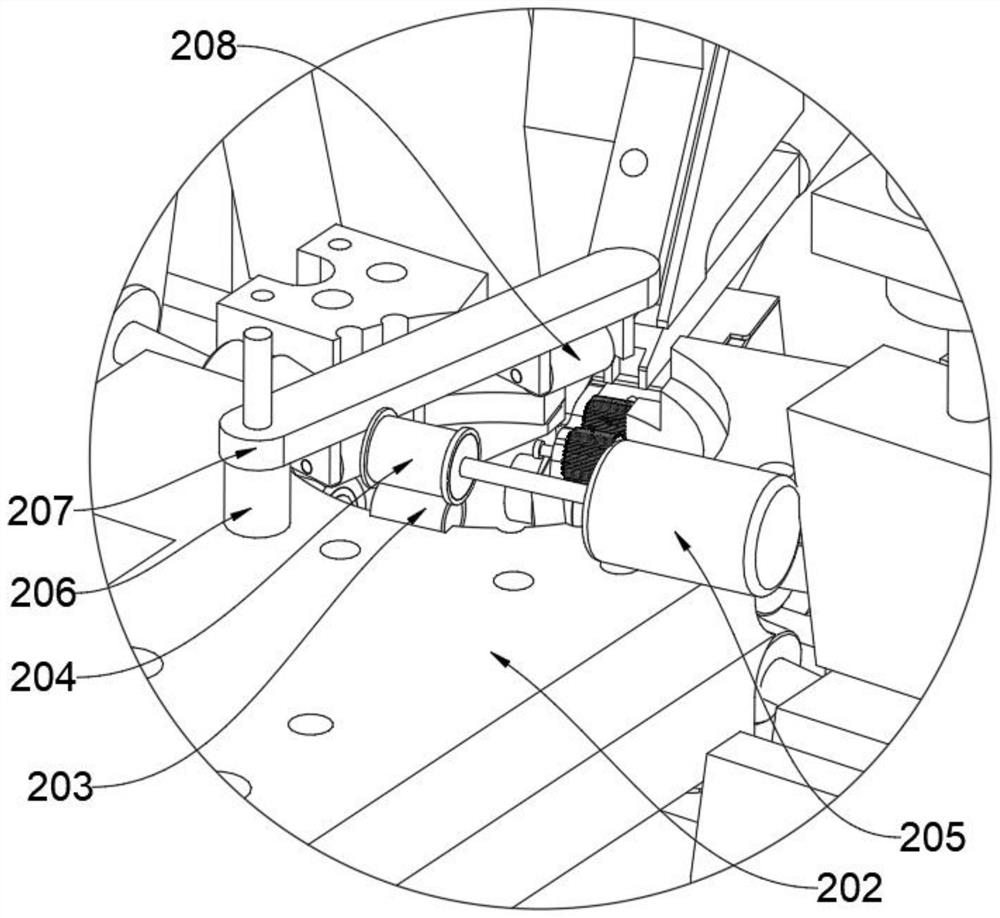

[0023] see Figure 1 to Figure 4 , an embodiment provided by the present invention: a magnetic encircling wire drawing machine that is easy to assemble 2 Including a fixed bottom block 201, a magnetic ring placing block 202, a winding sleeve 203, a sleeve transmission wheel 204, a winding transmission motor 205, a fixed sleeve 206, a height limit frame 207 and a magnetic ring limit wheel 208, the fixed bottom The magnetic ring placing block 202 is fixedly installed on the upper end surface of the block 201 by means of screw connection, the upper end surface of the magnetic ring placing block 202 is installed with a fixing sleeve 206 by means of screw connection, and the height limiter 207 is installed on the fixing sleeve 206 On the upper end face of the magnetic ring, two magnetic ring limit wheels 208 are installed at one end of the height limit frame 207. The height limit frame 207 and the magnetic ring limit wheel 208 can limit the rotation of the magnetic ring to prevent ...

Embodiment 2

[0026] On the basis of Embodiment 1, the wire drawing mechanism 5 includes a rotating movable block 501, a height adjusting rod 502, a pulley mounting frame 503, a wire tension adjusting wheel set 504, a guide angle adjusting rod 505, a bottom pulley mounting seat 506, and a guide pulley set 507 and the wire guide frame 508, a bottom pulley mounting seat 506 is installed on the outer side of the guide pulley group 507, a wire guide frame 508 is installed on one side of the bottom pulley mounting seat 506, and a guide angle adjustment rod 505 is installed on one side of the wire guide frame 508, A pulley mounting frame 503 is installed on the other side of the wire guide frame 508, a wire tension adjusting wheel group 504 is installed on one side of the pulley installation frame 503, and a height adjusting rod 502 is installed on the lower end of the pulley mounting frame 503. A rotating movable block 501 is installed on the outside, and a wire placing cylinder 6 is installed at...

Embodiment 3

[0028]On the basis of Embodiment 2, the magnetic ring placing block 202 is fixed on the upper end surface of the fixed bottom block 201 by screw connection, the lower end of the fixing sleeve 206 is welded and fixed on the upper end surface of the magnetic ring placing block 202, and the height limit frame 207 One end is extended to the inner side of the fixed sleeve 206 through a screw connection, and the lower end surface of the height limiter 207 is connected with two magnetic ring limit wheels 208 through the connecting shaft. When the magnetic ring rotates, it is limited to prevent deviation.

[0029] The upper end surface of the magnetic ring placing block 202 is provided with a magnetic ring positioning groove, the winding sleeve 203 is arranged on the inner side of the magnetic ring positioning groove, the winding transmission motor 205 is fixed on the upper end surface of the magnetic ring placing block 202 by screw connection, and the sleeve drives The wheel 204 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com