Linear actuator

A technology of linear actuators, actuators, applied in transmissions, beds, sofas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

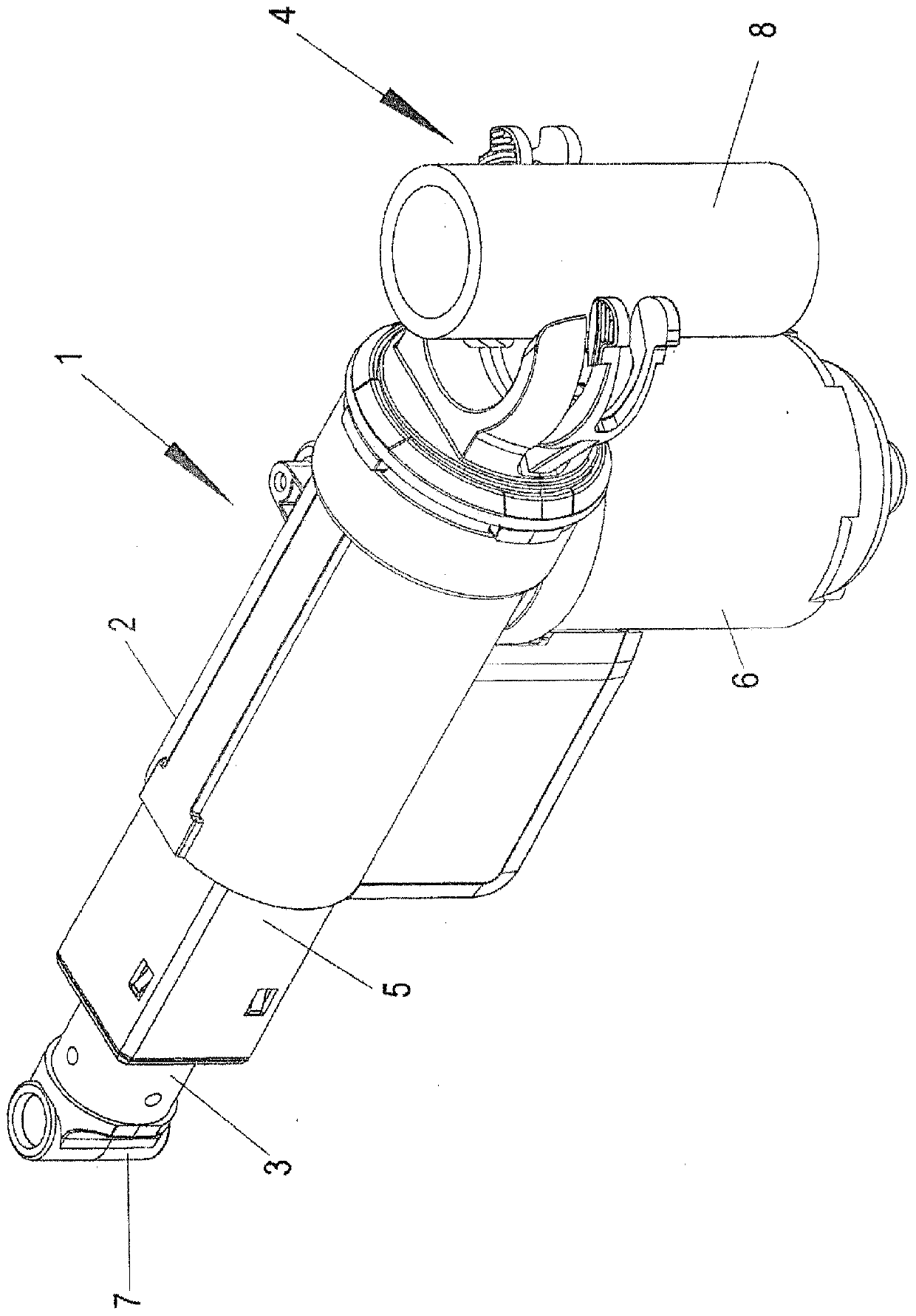

[0032] figure 1 A linear actuator 1 is shown comprising a support frame 2 , a driven element 3 movable at the front end of the support frame 2 and a mount 4 at the rear end of the support frame 2 .

[0033] The driven element 3 is a so-called "inner tube" that is telescopic inside an outer tube 5 connected to the support frame 2 . An electric motor 6 is connected to the support frame 2 and drives a spindle arranged in the support frame 2 and the outer tube 5 . The driven element 3 is connected to a spindle nut which is threaded on the spindle. The spindle nut is secured against rotation. When the motor 6 drives the spindle, the spindle nut and thus the driven element 3 is driven out of or into the outer tube 5 . The direction of movement of the driven element 3 depends on the direction of rotation of the electric motor 6 .

[0034] The driven element 3 is connected to a front mount 7 which can be used to connect the driven element 3 to eg a part of a bed.

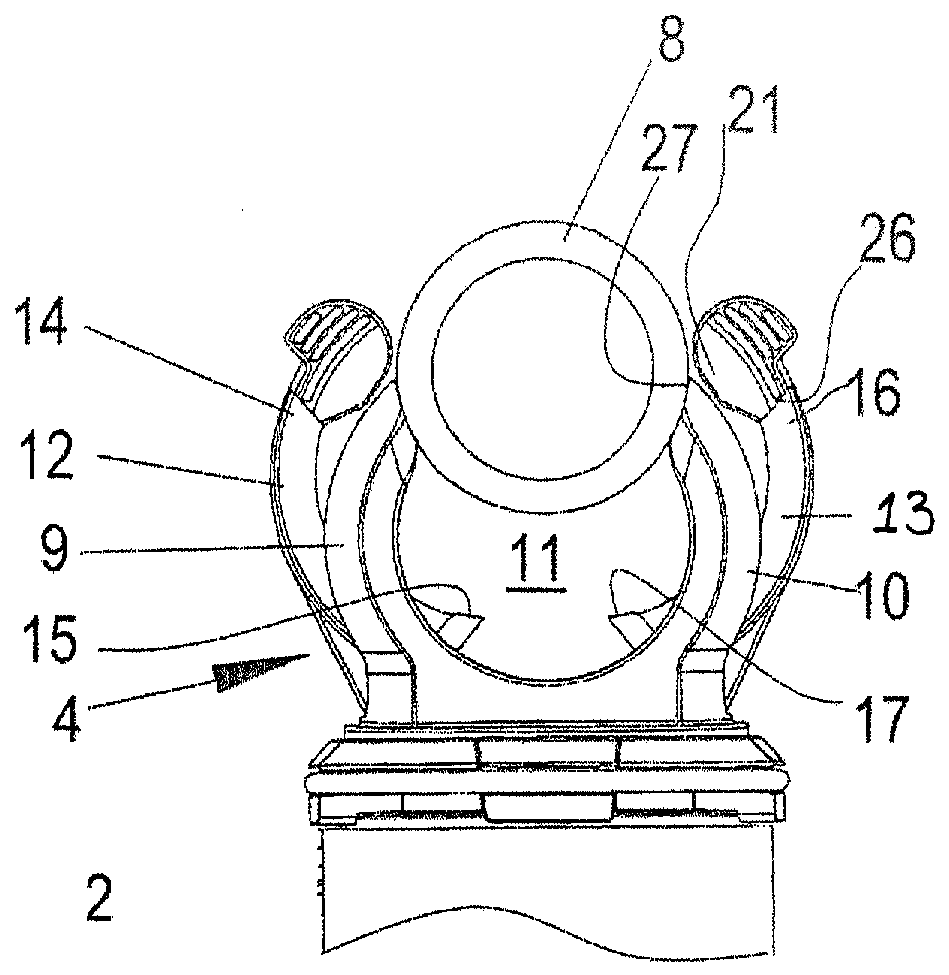

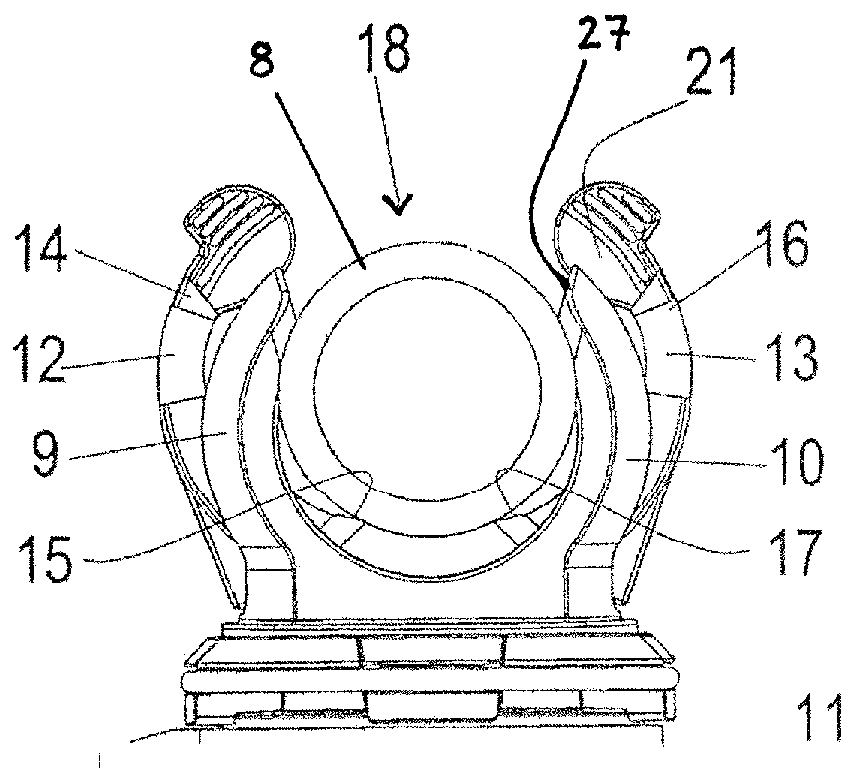

[0035] A mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com