PVC pipe interface auxiliary glue application equipment

A technology of pipe interface and gluing, applied in mechanical equipment, coating, material gluing, etc., can solve the problems of labor-consuming, uneven application of glue, difficult assembly, etc., and achieve the effect of easy assembly and uniform application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

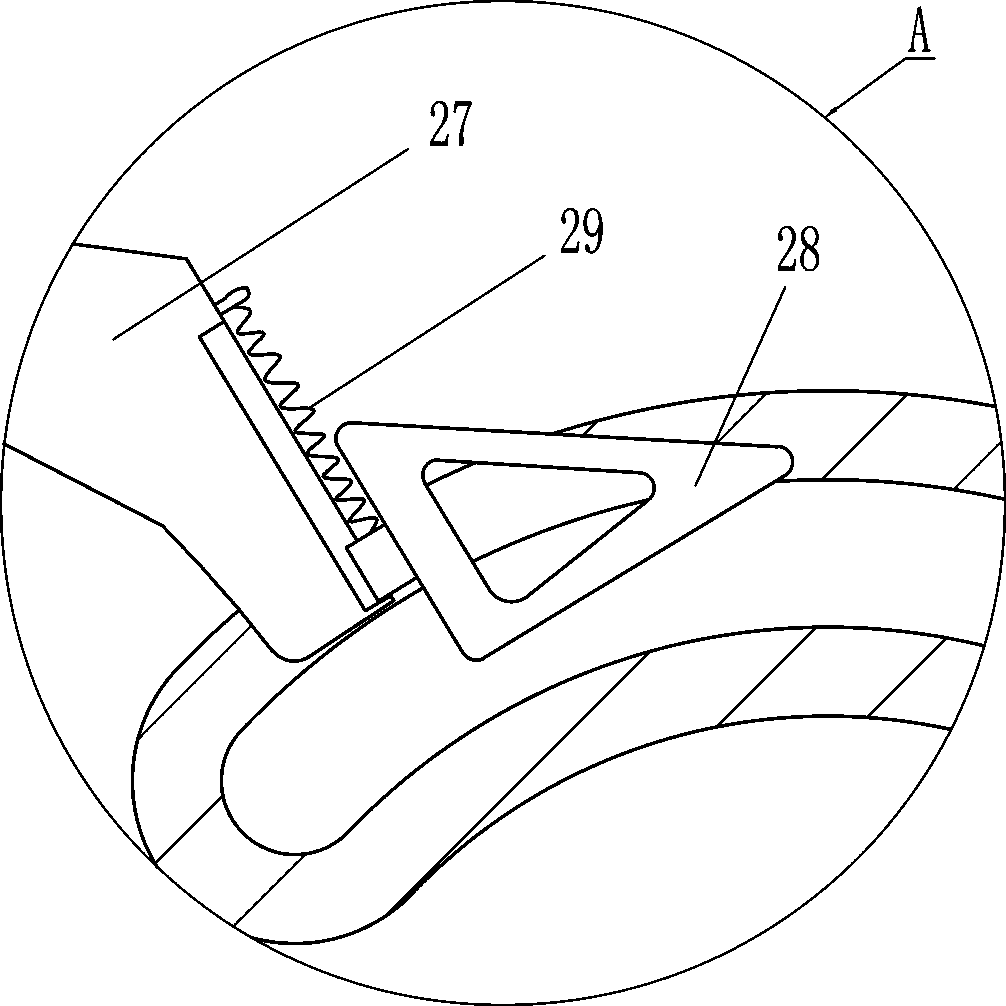

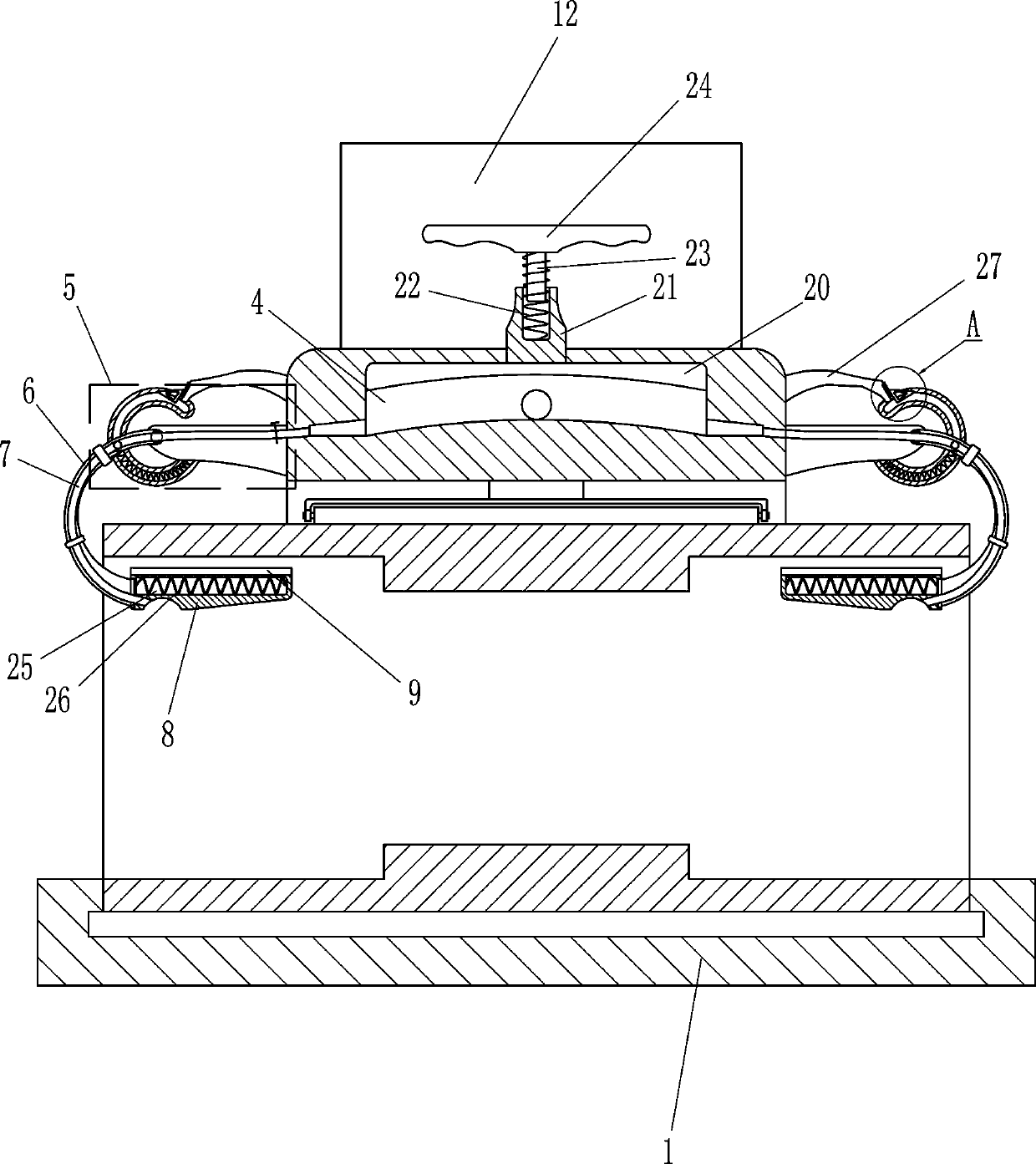

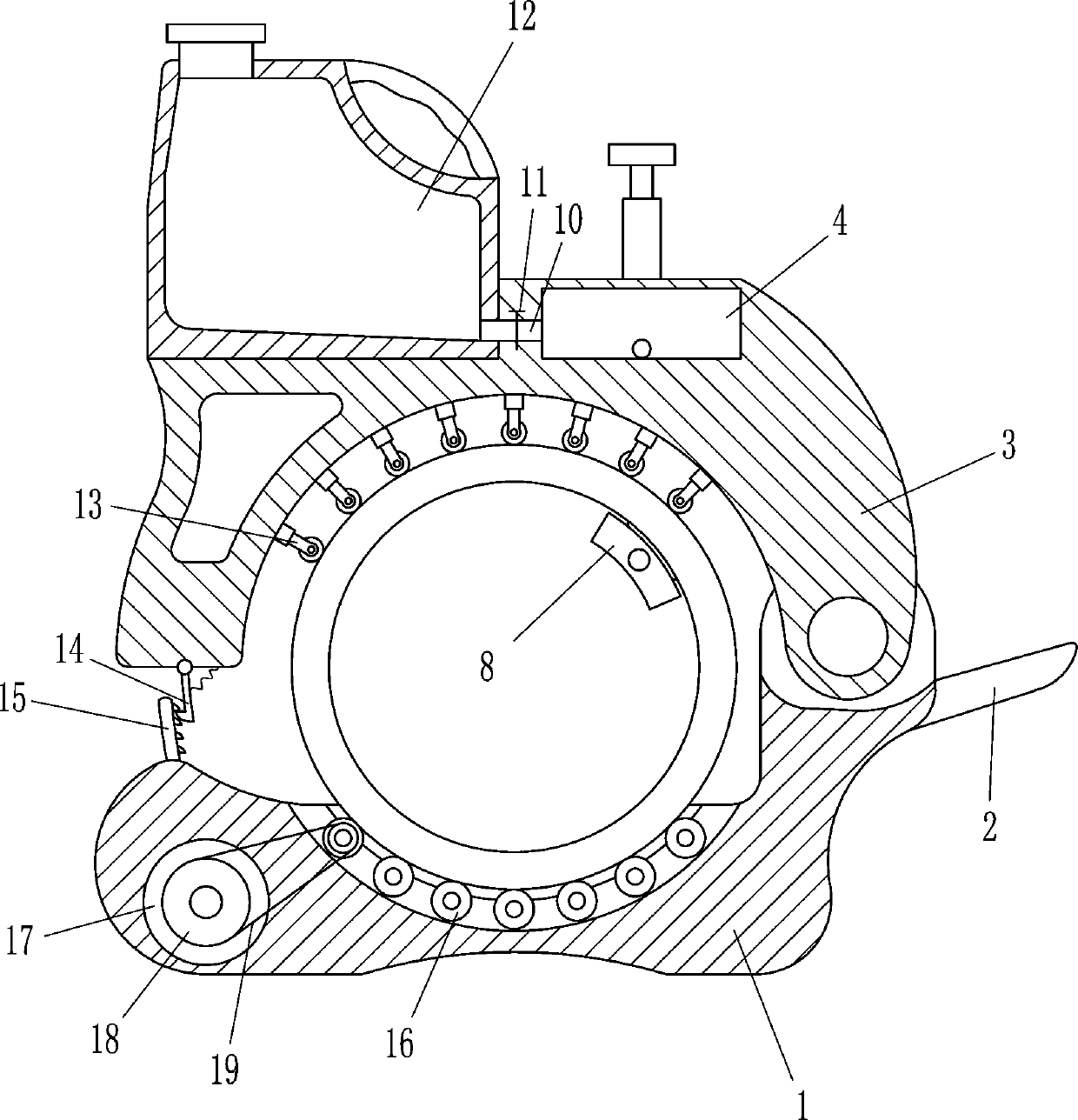

[0019] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown in the figure, an auxiliary gluing equipment for PVC pipe joints includes a base 1, an installation block 2, an arc-shaped pressing block 3, a rubber box 4, a rotating device 5, an arc-shaped plate 6, a hose 7, a hose nozzle 8, a scraper Plate 9, input pipe 10, valve 11, material box 12, first roller 13, locking teeth 14, bar 15, second roller 16 and rotating motor 17, base 1 is connected with arc-shaped pressing block 3 on the shaft, base 1 A mounting block 2 is provided on the side wall of the upper shaft joint, a plastic box 4 is provided on the arc-shaped pressing block 3, and a rotating device 5 that can rotate with an arc-shaped plate 6 is installed on both sides of the arc-shaped pressing block 3. A hose 7 is clamped on the plate 6, and a hose nozzle 8 is detachably installed on the arc-shaped plate 6. One end of the hose 7 is connected to the hose nozzle 8, and the o...

Embodiment 2

[0023] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a PVC pipe interface auxiliary glue application equipment, on the basis of embodiment 1, also includes a pressure plate 20, a straight sleeve 21, a second elastic member 22, a connecting rod 23 and a grip rod 24, and the rubber box 4 is movable A pressure plate 20 is provided in the form of a bolt, and a straight sleeve 21 is arranged on the pressure plate 20 through bolt connection. A connecting rod 23 is arranged inside the straight sleeve 21, and a second elastic member 22 is arranged between the straight sleeve 21 and the connecting rod 23. The second elastic member 22 is a compression spring, and the connecting rod 23 is provided with a grip rod 24 .

[0024] The device is operated in this way, and the specific operation method is as follows: When the hose nozzle 8 is transferred to the PVC pipe joint, then the valve 11 on the hose 7 is opened, and the pressure plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com