Full-automatic inner diameter sorting machine for springs

A sorting machine, fully automatic technology, applied in the field of sorting machines, can solve the problems of large manpower demand, cumbersome inner diameter of springs, etc., and achieve the effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

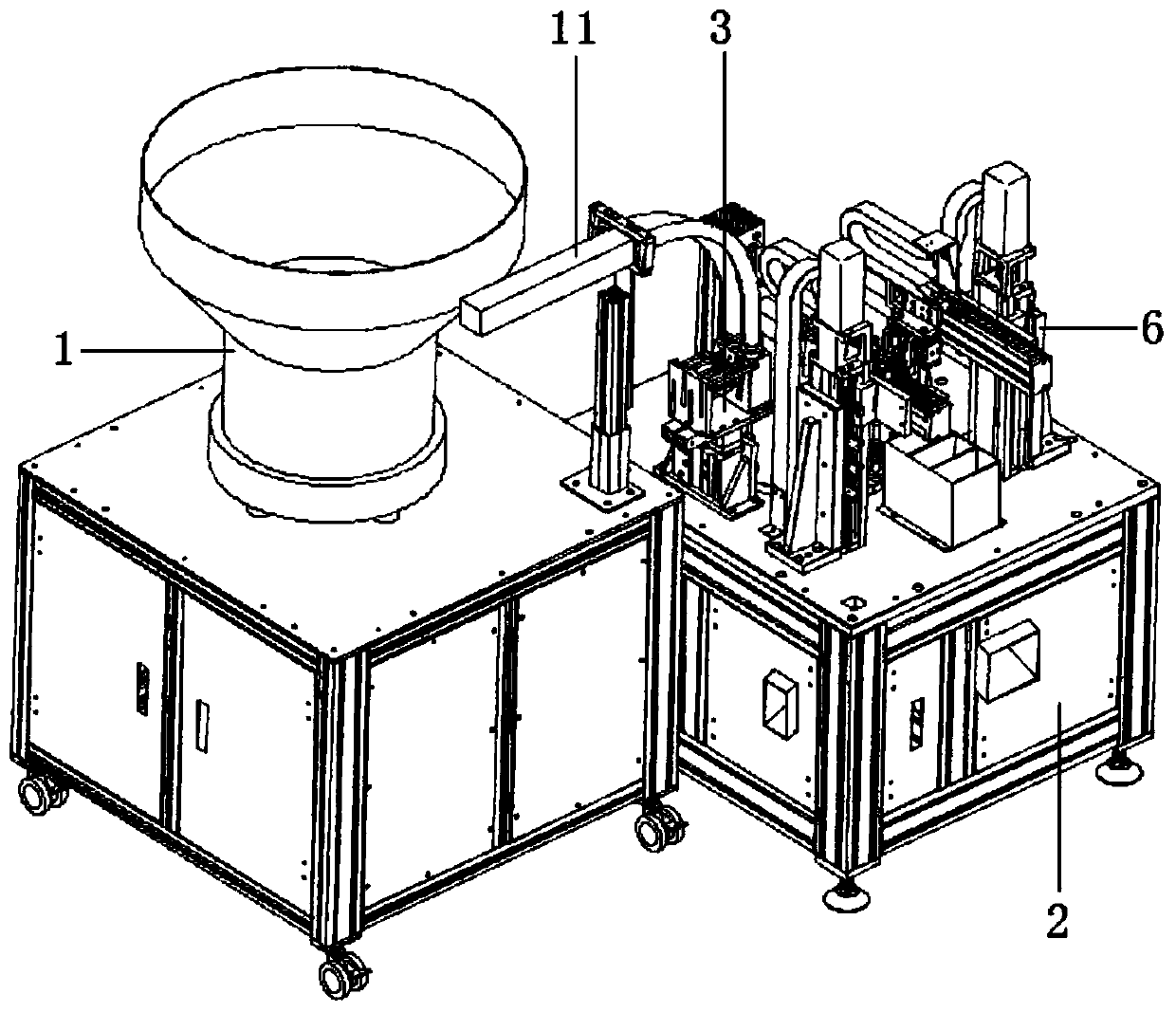

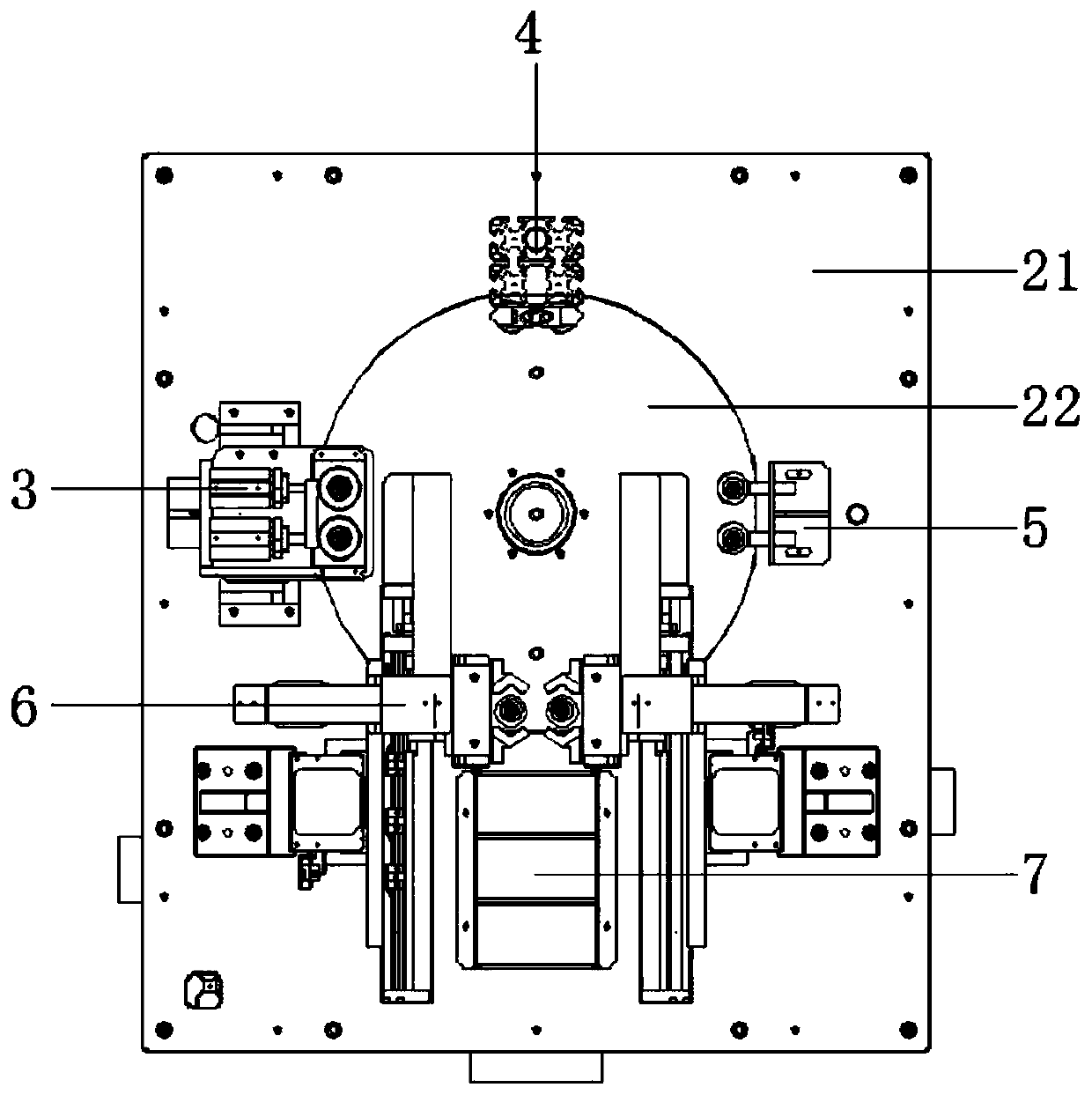

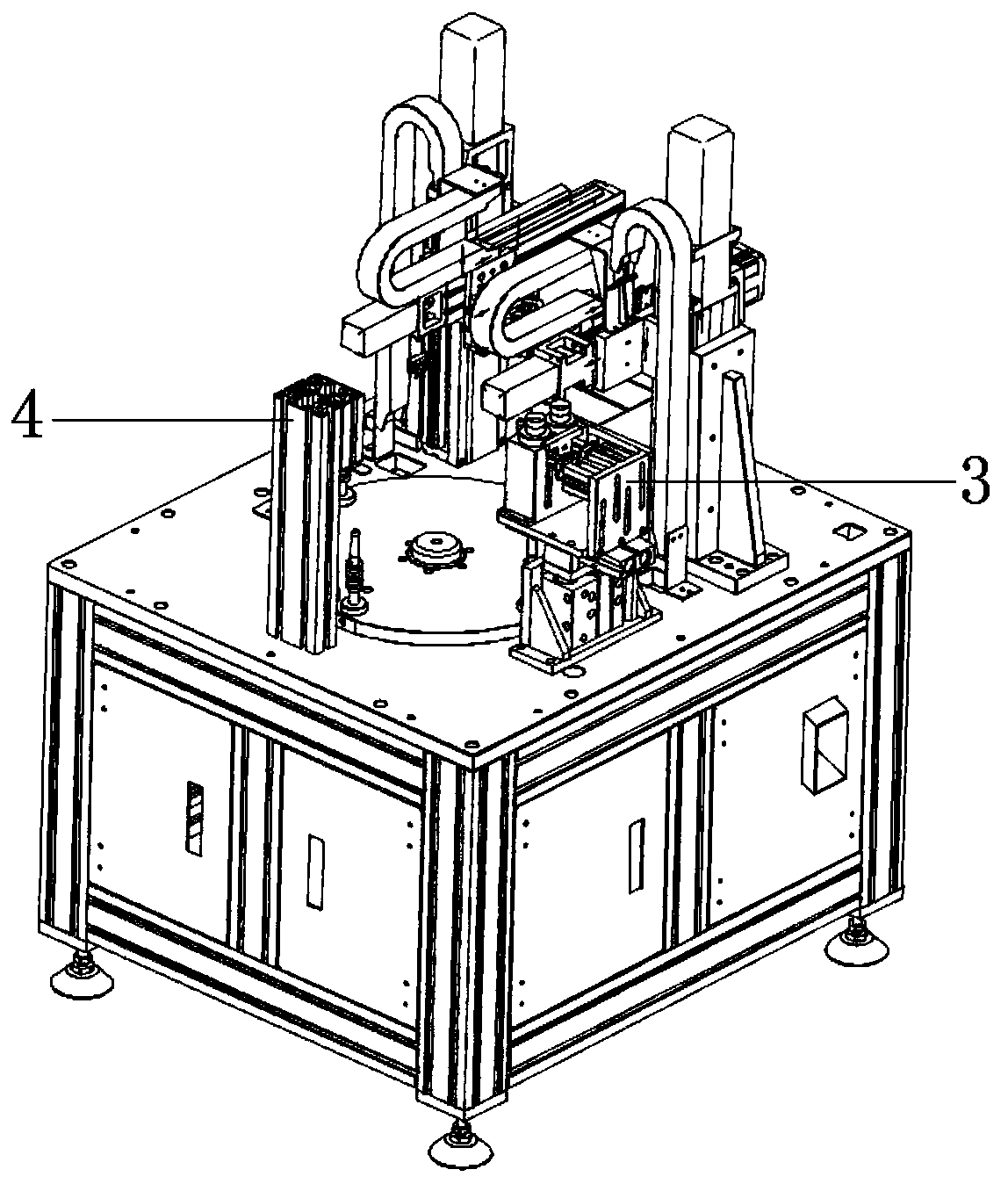

[0057] A spring 8 automatic inner diameter sorting machine, said spring 8 automatic inner diameter sorting machine includes: a sorting machine main body 2, a material placement component 3, a calibration component 4, a detection component 5, a grasping component 6 and a discharge pipeline7. Among them, the moving part 22 on the main body 2 of the sorting machine moves in the first direction, and other parts are arranged in the first direction. A mandrel 221 on the moving part 22 passes through the feeding assembly 3, the alignment assembly 4, and the detection assembly in sequence. 5 and the grasping assembly 6; the spring 8 is placed on the mandrel 221 by the material placement assembly 3; the position of the spring 8 on the mandrel 221 is calibrated by the calibration assembly 4, so that the position of the spring 8 is more upright, and the position of the spring 8 The inner wall and the mandrel 221 are more fit; the position of the spring 8 on the mandrel 221 is detected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com