A physical pulse wall breaking pulping device

A pulse and physical technology, applied in fiber raw material treatment, water/steam pretreatment, textile and papermaking, etc., can solve the problems of large pollution and low pulp yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0068] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

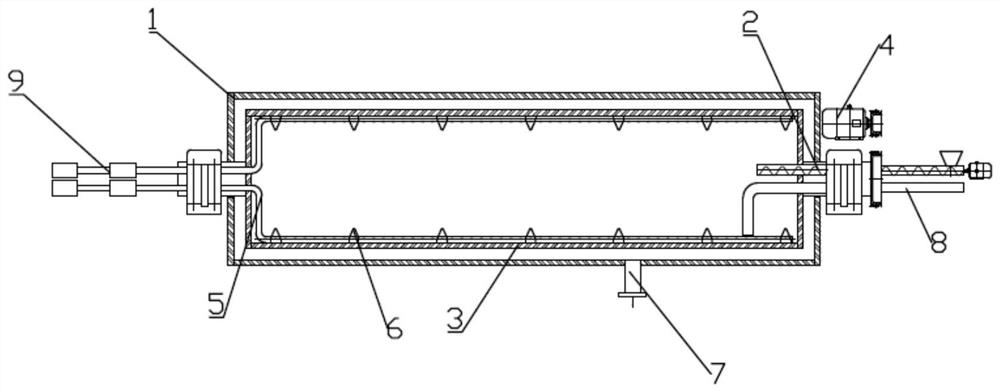

[0070] Such as figure 1 As shown, the present embodiment provides a horizontal physical pulse broken wall pulping device, wherein the device has a shell 1, and the shell 1 has a cylindrical structure of anti-corrosion and anti-rust metal shell; along the axis of the shell 1 Direction, a feed port 2 is opened on the shell 1; an inner barrel 3 is set near the inner wall of the outer shell, the distance between the outer wall of the inner barrel 3 and the inner wall of the outer shell 1 is 10-20cm, and the inner barrel 3 The opening is set on the side where the feed inlet is located; the inner barrel wall is composed of a 10mm thick carbon steel sieve plate with multiple openings (the sieve hole is 3-5mm);

[0071] A rotating shaft 4 is arranged on the wall of the inner barrel close to the feed inlet, and the rotating shaft 4 drives the inner barrel 3 to rotate in the axial direction in the shell 1;

[0072] Along the axial direction of the inner bucket 3, a plurality of high-pr...

Embodiment 2

[0087] Using the device of the above-mentioned embodiment 1, the grass corn stalks are used as raw materials, and the impurities and dust in the raw materials are removed in the dedusting device by removing impurities and dust, and the raw materials are crushed into 1-5 cm sections in the material pulverizer. , Sieve and separate the broken material after crushing to obtain the raw material for pulping; send it into the inner barrel through the feed port through the air blowing or screw extrusion;

[0088] Since the raw material is not softened, the raw material is first softened, including the following steps:

[0089] a. Send 100kg of materials, 7kg of sodium hydroxide, 300kg of clear water or recycled water into the inner barrel, and use the heating unit of the device to heat to 100-120°C to soften; after softening for 30 minutes, use the gravity of the wastewater to pass the wastewater through The sieve holes on the sieve plate flow out of the device from the drain outlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com