A hybrid magnetic steel AC excitation memory motor

A memory motor, AC excitation technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits characterized by magnetic materials, magnetic circuits, etc., can solve the problems of increasing the copper consumption of the motor and reducing the efficiency of the motor , to achieve the effect of improving motor efficiency, increasing high-order harmonics and output capacity, and reducing electric excitation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

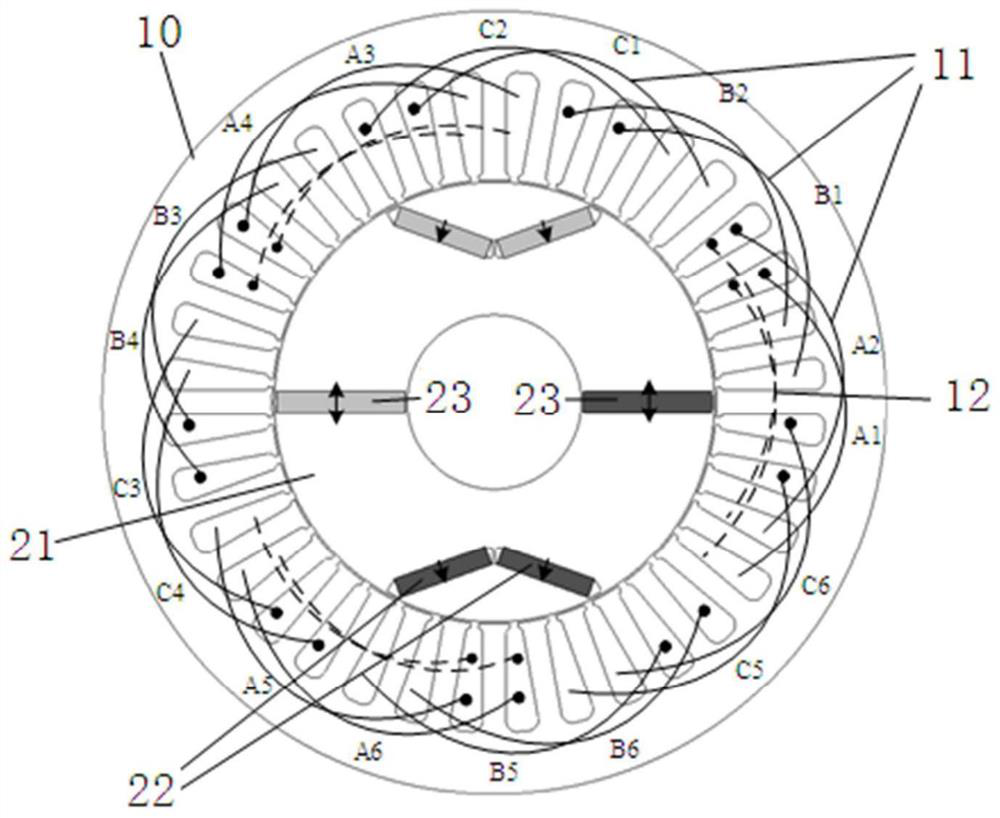

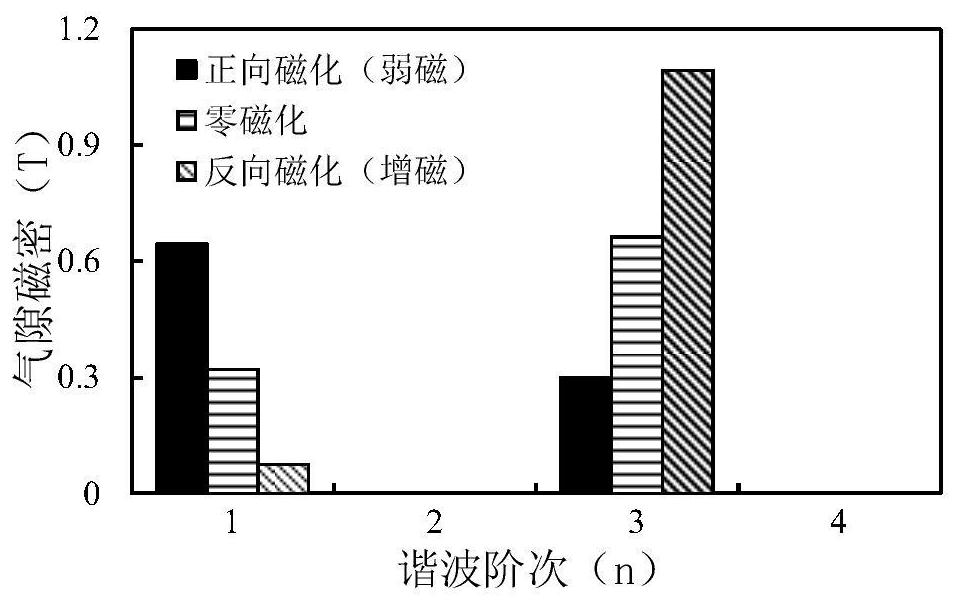

[0049] Example 1 With three-phase inner rotor m=3, N s =36, p =3i (i=1) as an example

[0050] Three-phase main winding m=3, number of stator slots N s =36, the number of pole pairs of the main winding p =3, the number of pole pairs of pulse excitation winding i=1. The phase numbers of the main winding and the pulse excitation winding can also be different.

[0051] In this embodiment, the main windings are A, B, and C phases, and the A phase can be formed by connecting A1-A6 coils in series, or can be connected in parallel by A1-A2, A3-A4, and A5-A6 respectively. Phase B and C And so on. The AC pulse excitation windings are X, Y, and Z phases. Only the X phase is shown in the figure, and the X, Y, and Z phases are counterclockwise sequentially with a difference of 120°.

[0052] When p=3i, the number of high coercivity magnets is 2i groups, and the number of built-in tangential magnets is 2i. In this embodiment 1, the number of high coercivity magnets and built-in ta...

Embodiment 2

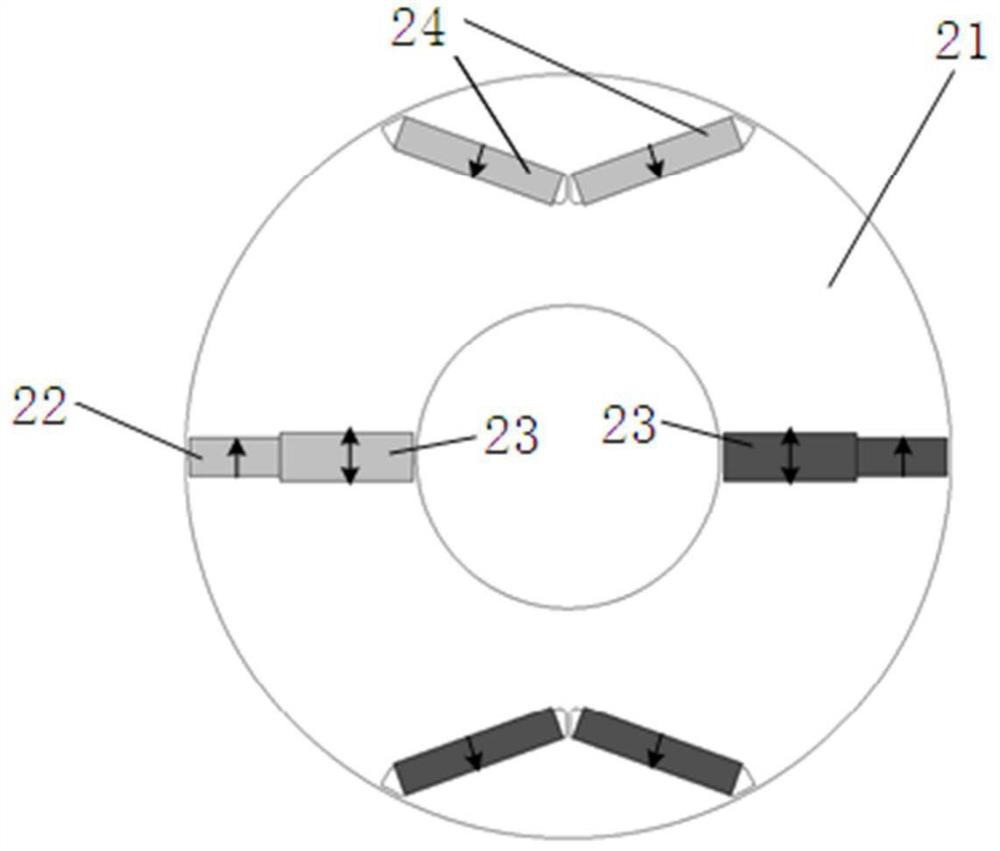

[0067] When p=2i, and i>1, the number of high-coercivity magnets is 2i groups, and the number of built-in tangential magnets is i.

[0068] The i built-in tangential magnets are uniformly arranged along the circumferential direction of the rotor core, and the magnetization directions of two adjacent built-in tangential magnets are the same along the circumferential direction. A pair of adjacent high-coercivity magnets with opposite polarities is arranged between two adjacent built-in tangential magnets, and an iron core is formed between a group of high-coercivity magnets and an adjacent built-in tangential magnet pole.

[0069] Such as Figure 4 As shown, the figure shows a schematic diagram of the structure when p=2i and i=2.

Embodiment 3

[0071] When p=5i, the number of high coercivity magnets is 4i groups, and the number of built-in tangential magnets is 2i. The 2i built-in tangential magnets are uniformly arranged along the circumferential direction of the rotor core, and the magnetization directions of two adjacent built-in tangential magnets are opposite along the circumferential direction. Two high-coercivity magnets with the same polarity are set between two adjacent built-in tangential magnets, and the high-coercivity magnets and adjacent built-in tangential magnets and the adjacent two high-coercivity magnets An iron core pole is formed between the coercive magnetic steels.

[0072] Such as Figure 5 As shown, the schematic diagram of the structure when p=5i and i=1 is shown in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com