Voltage-induced nano-dot magnetization uniaxial-to-vortex-state nonvolatile adjustment and control method

A voltage regulation and nano-dot technology, applied in the field of low-power nano-dot magnetization regulation, can solve problems such as being in the theoretical stage, without reliable experiments to prove the correctness, and reducing the integration density of vortex memories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

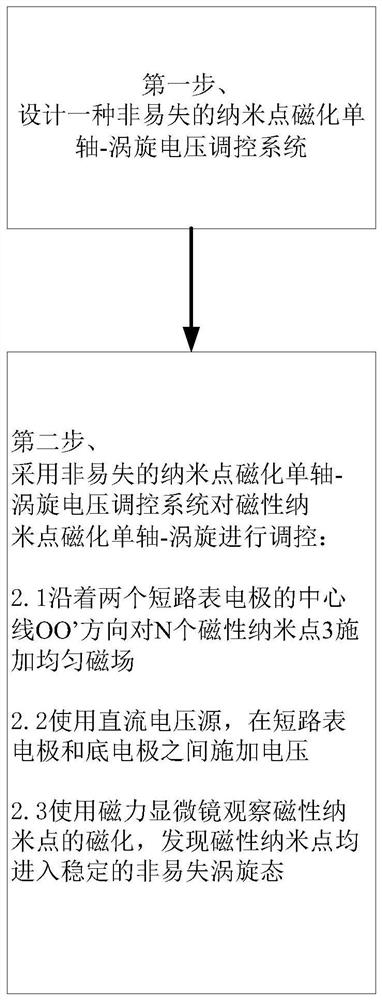

Method used

Image

Examples

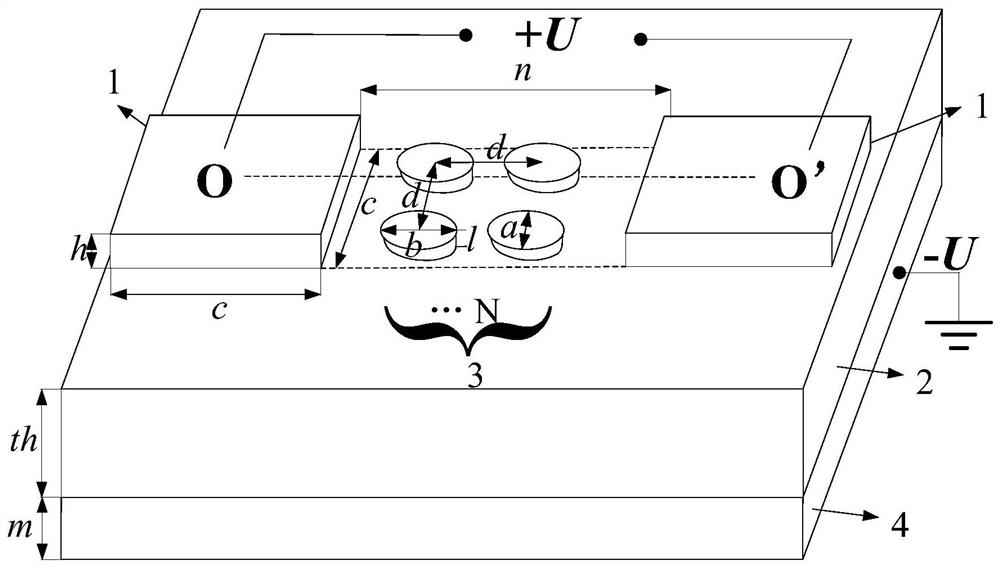

Embodiment 1

[0038] A pair of short-circuit surface electrodes 1 with a side length c of 0.5 mm and a thickness h of 100 nm were constructed on a piezoelectric layer 2 with a [011] crystal orientation and a thickness th of 0.5 mm by electron beam evaporation and peeling off. Then, 4 (N=4) elliptical columnar magnetic nano-dots 3 with a size of 324nm × 360nm × 24nm (a × b × l) were constructed between the two short-circuit meter electrodes 1, and the long axis direction of the magnetic nano-dots 3 and The center lines OO' of the two short-circuited meter electrodes 1 are parallel. The distance d between the centers of two adjacent magnetic nano-dots 3 is 2 micrometers. The grounded bottom electrode 4 has a thickness m of 200 nm.

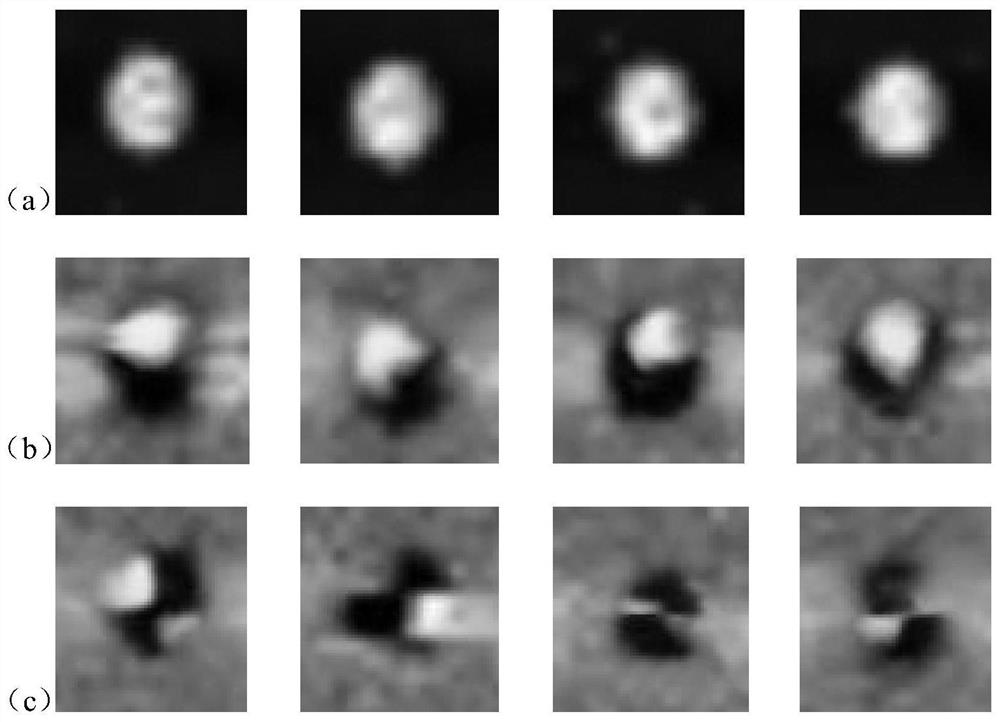

[0039] Firstly, a magnetic field of ~0.2T is applied along the long axis direction of the magnetic nano-dots 3 (ie, the OO' direction), to initialize the magnetization states of all the magnetic nano-dots 3 to a uniaxial state. After that, a voltage of U=-200V i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com