Quick-change forming die for preparing large-diameter magnesium alloy pipes

A technology for forming dies and magnesium alloys, applied in metal extrusion dies, manufacturing tools, control equipment for metal extrusion, etc. It can achieve the effect of stable internal temperature of the mold, improving production efficiency and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

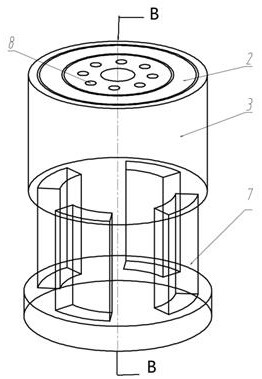

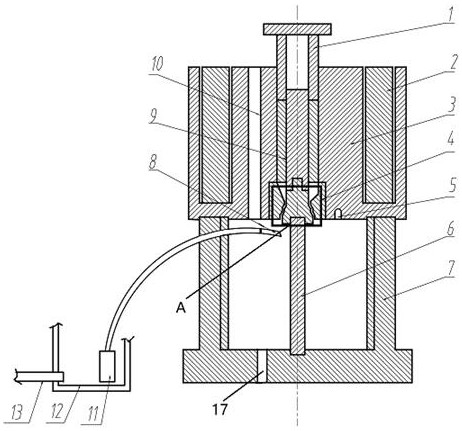

[0056] The present embodiment 1: see figure 1 and figure 2 , a quick-change forming die for preparing large-diameter magnesium alloy pipes, including a base 7 with an inner hole, the base 7 is provided with a water leakage port 17 communicating with the inner hole, the base 7 includes a support plate, through which a support plate The base 7 is fixed and supported, and the top of the base 7 is provided with a barrel 3 facing the inner hole. The middle part of the barrel 3 is provided with an extrusion chamber for storing the billet 9, and the extrusion chamber is provided with a And the extrusion rod 1 moving up and down along the extrusion chamber, the barrel 3 is provided with a heating device for heating the blank 9, the bottom of the barrel 3 is provided with a die located at the inner hole orifice, the die and the barrel 3 is fastened by screw connection, which is designed to realize the detachable connection between the die and the barrel 3.

[0057] The heating devic...

Embodiment 2

[0079] Example 2, see Figure 6-Figure 8 , the molded piece is a second molded piece 18, the top of the second molded piece 18 is provided with a second threaded column 182, and the second threaded column 182 is threadedly connected with the inner hole at the bottom of the guide rod 14, and the bottom of the second molded piece 18 is provided with a The second thread groove 183 is threadedly connected with the top post of the guide rod 16 .

[0080] The die is a second die 181, and a second extrusion channel with continuous extrusion, bending, shearing and diameter expansion of the blank 9 is formed between the outer surface of the second molding 18 and the inner wall of the second die 181, wherein the second The extrusion channel includes the first curved shear zone C1, the second curved shear zone C2 and the third curved shear zone C3, the first curved shear zone C1, the second curved shear zone C2 and the third curved shear zone C3 all bend outwards and form a semi-ring st...

Embodiment 3

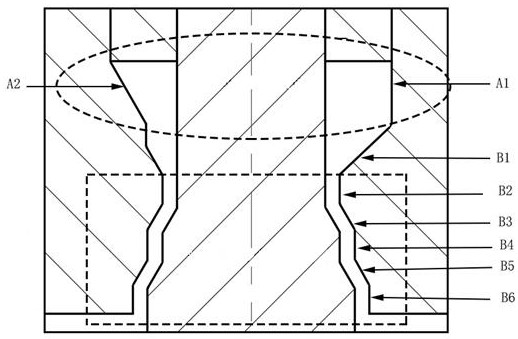

[0082] Example 3, see Figure 9-Figure 11 , the molding is the third molding 19, the top of the third molding 19 is provided with a third threaded column 192, and the third threaded column 192 is threadedly connected with the inner hole at the bottom of the guide rod 14, and the bottom of the third molding 19 is provided with The third thread groove 193 is threadedly connected with the top post of the guide rod 16 .

[0083] The die is a third die 191, and a third extrusion channel with continuous extrusion torsional shearing of the blank 9 is formed between the outer surface of the third molding 19 and the inner wall of the third die 191, wherein the third extrusion channel It includes the first torsional shear zone D1, the second torsional sizing zone D2 and the third torsional shear zone D3 connected in sequence from top to bottom, the first torsional shear zone D1 and the third torsional shear zone D3 are outward After being inclined, it is bent and extended downwards, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com