A multi-step continuous bending device for arc components

A press-bending device and multi-step technology, which are applied to storage devices, feeding devices, positioning devices, etc., can solve the problems of high cost, low efficiency, and inability to meet mass production, and achieve simple forming processes and bending modules. Simple structure, simple and convenient bending process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

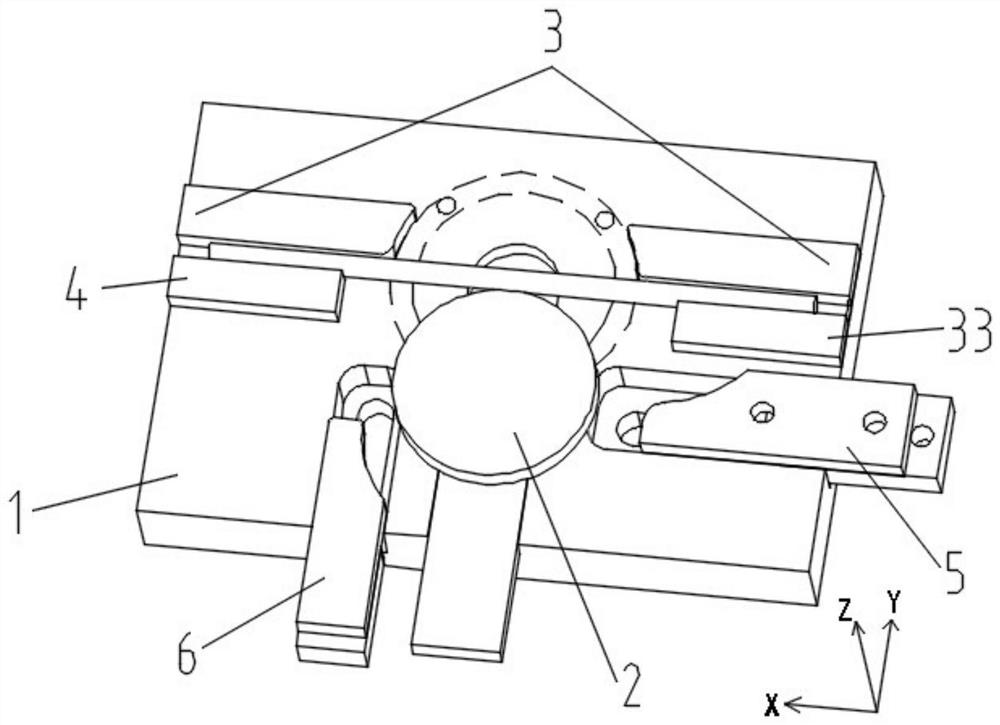

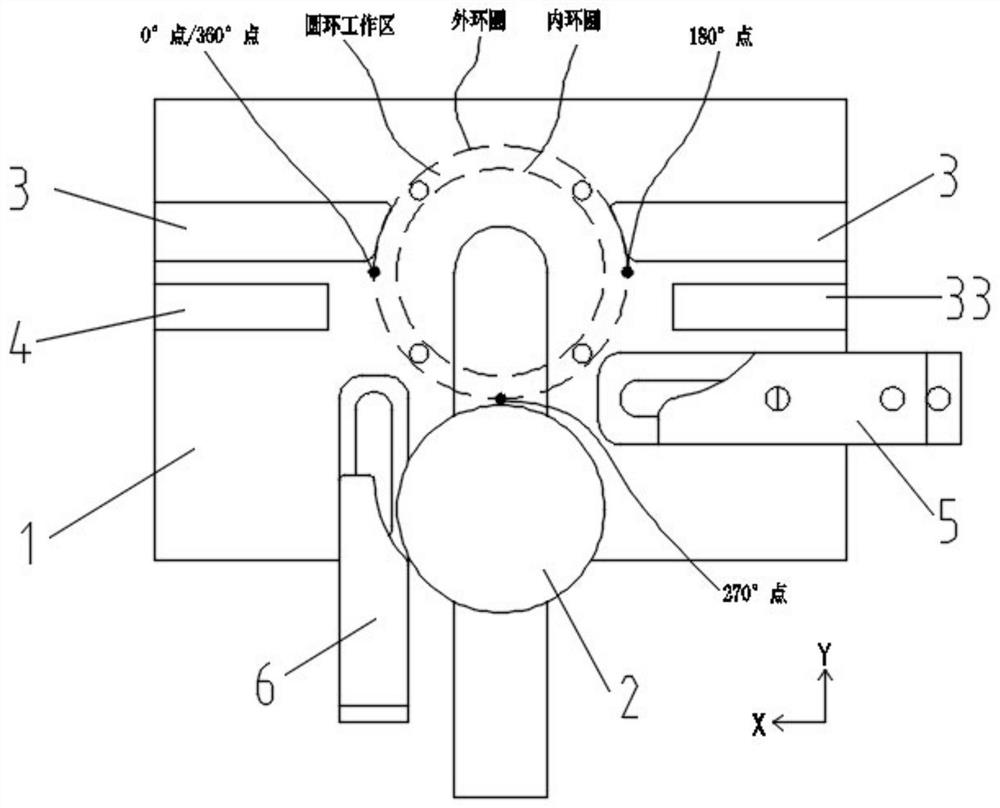

[0049] A multi-step continuous bending device for arc-shaped members in this embodiment, such as figure 1 and figure 2 As shown, it includes a base 1, on which a circular die assembly 2 is slidably arranged in the Y direction, and half rings are arranged on both sides of the circular die assembly 2 along the X direction on the base 1 Shaping assembly 3, the side of the half-ring shaping assembly 3 close to the circular die assembly 2 is provided with a starting positioning block 4 along the X direction, and the half-ring shaping assembly 3 and the starting positioning block 4 are arranged along the X direction. A channel is provided in the direction for components to pass through; the other side of the circular die assembly 2 is provided with a three-quarter ring die assembly 5 sliding along the X direction.

[0050] The base 1 is fixed on the working surface by bolts, and the top of the base 1 is provided with a circular die assembly 2, a half-ring shaping assembly 3, a thr...

Embodiment 2

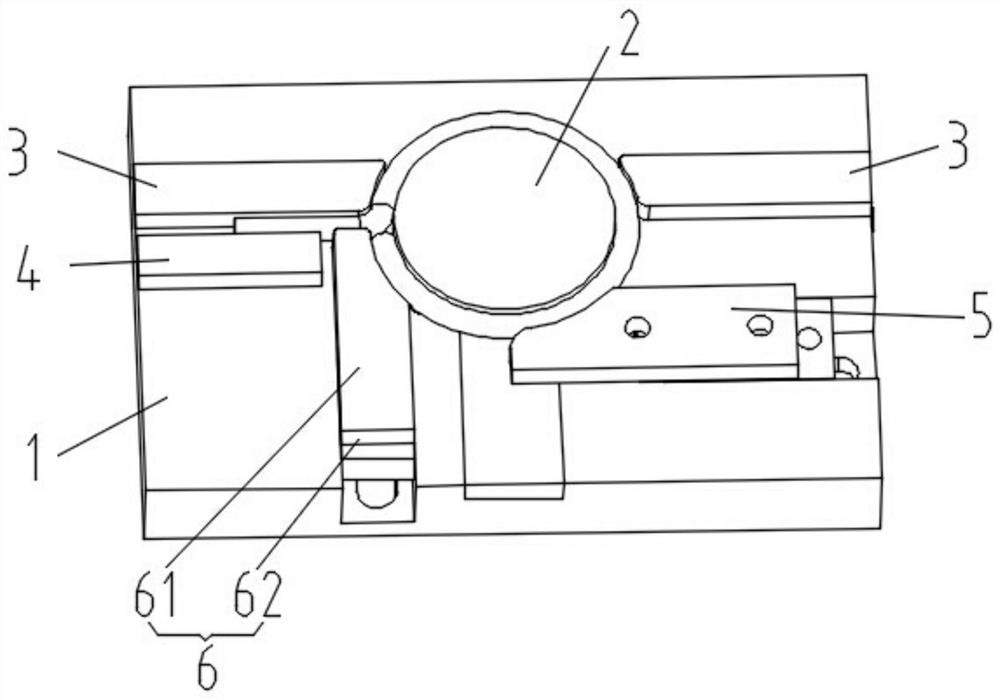

[0059] This embodiment is further optimized on the basis of embodiment 1, such as image 3 , Figure 4 , Figure 16 As shown, one side of the circular die assembly 2 is slidably provided with a full-ring die assembly 6 along the Y direction; the full-ring die assembly 6 includes a full-ring die 61 and a full-ring traction block 62 , the whole-ring traction block 62 is slidably arranged on the base 1 along the Y direction, and the top of the whole-ring traction block 62 is equipped with a whole-ring die 61 and drives the whole-ring die 61 to move along the Y direction. One end of the die 61 close to the circular die assembly 2 is provided with a die arc corresponding to the bending outer contour of the component.

[0060] On the base 1 corresponding to the 360° point of the circular working area, there is a first chute with an opening along the Y direction, and a full-ring traction block 62 is slidably arranged in the first chute, and the top of the entire-ring traction block...

Embodiment 3

[0072] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 5-Figure 7 and Figure 14 As shown, the semi-ring shaping assembly 3 includes a first shaping block 31 and a second shaping block 32, and the first shaping block 31 is provided on both sides of the circular die assembly 2 along the X direction. and the second starting-end shaping block 32; the first starting-ending shaping block 31 is arranged parallel to the starting-end positioning block 4, and there is provided along the X direction between the first starting-end shaping block 31 and the starting-end positioning block 4 for members to pass through channel; the ends of the first starting-end shaping block 31 and the second starting-end shaping block 32 close to the circular die assembly 2 are provided with a die arc corresponding to the outer contour of the member.

[0073] The first shaping block 31 and the second shaping block 32 are respectively arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com