A new energy straw coal processing equipment

A kind of processing equipment, straw coal technology, applied in the field of new energy straw coal processing equipment, can solve the problems of poor forming effect, single forming specification, narrow application range, etc., to facilitate fastening work, prevent sliding overtravel, and enhance practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

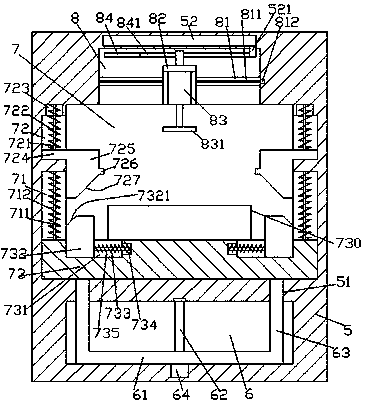

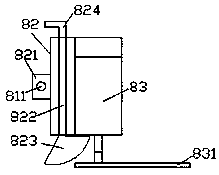

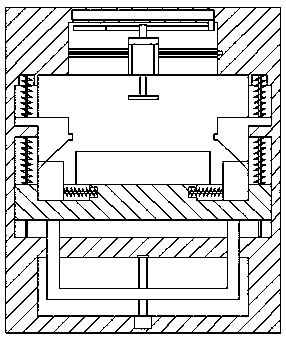

[0021] Such as Figure 1-Figure 4 As shown, a new energy straw coal processing equipment of the present invention includes a frame body 5, a pressurizing part 7 is provided inside the frame body 5, and a lift is provided inside the frame body 5 below the pressurizing part 7. Cavity 6, the top surface of the pressurizing part 7 is provided with a top groove 8 extending left and right, the top groove 8 is provided with a sliding block 82, and the front end surface of the sliding block 82 is fixed with a pressure drive device 83, the bottom of the pressurization driving device 83 is provided with a pressurization end 831 that extends into the pressurization part 7 and is screwed and connected. The guiding groove 71 and the second guiding groove 72 arranged above the first guiding groove 71, the first guiding groove 71 is provided with a first guiding rod 711 extending up and down, the second guiding groove 71 The inner top surface of the row groove 72 is provided with a first gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com