Machine for drying, heating and shaping hair

A styling machine and heating mantle technology, applied in hairdressing equipment, hair drying devices, hair or scalp washing devices, etc., can solve problems such as messy placement, inconvenient access, fixed and non-adjustable height of hair dryers, etc., to achieve Automatic height adjustment, convenient placement and access, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

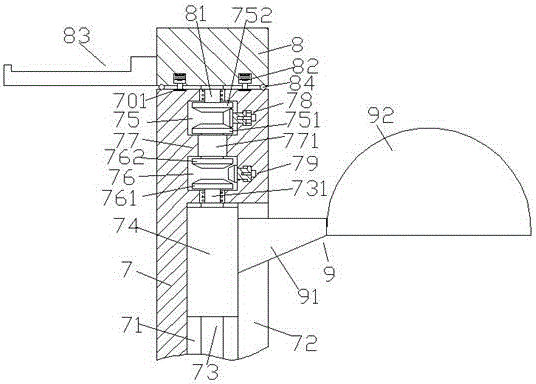

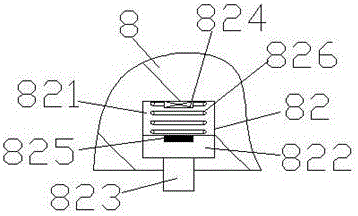

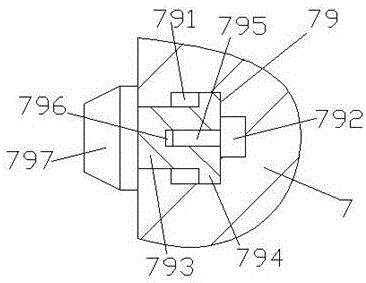

[0020] Such as Figure 1-Figure 4 As shown, a drying heating setting machine of the present invention includes a frame 7, a rotating seat 8 arranged above the frame 7, and a drying part 9 composed of a support rod 91 and a heating cover 92. The machine The interior of the frame 7 is provided with a downwardly extending first sliding chamber 71, the right side of the first sliding chamber 71 is provided with a sliding chamber 72 arranged along the first sliding chamber 71, and the first sliding chamber 71 is provided with A threaded threaded rod 73, on which a sliding block 74 is rotationally fitted and connected, and the right end surface of the sliding block 74 is fixedly connected with the support rod 91, and the top of the first sliding chamber 71 The frame 7 is provided with a first empty slot 75 and a second empty slot 76, an isolation plate 77 is arranged between the first empty slot 75 and the second empty slot 76, and a spacer 77 is arranged in the first empty slot 75....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com