Locking structure with bidirectional insertion type guide plates

A locking structure and plug-in technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as easy to open outwards, unstable guide plates, etc., achieve uniform force, reduce costs, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

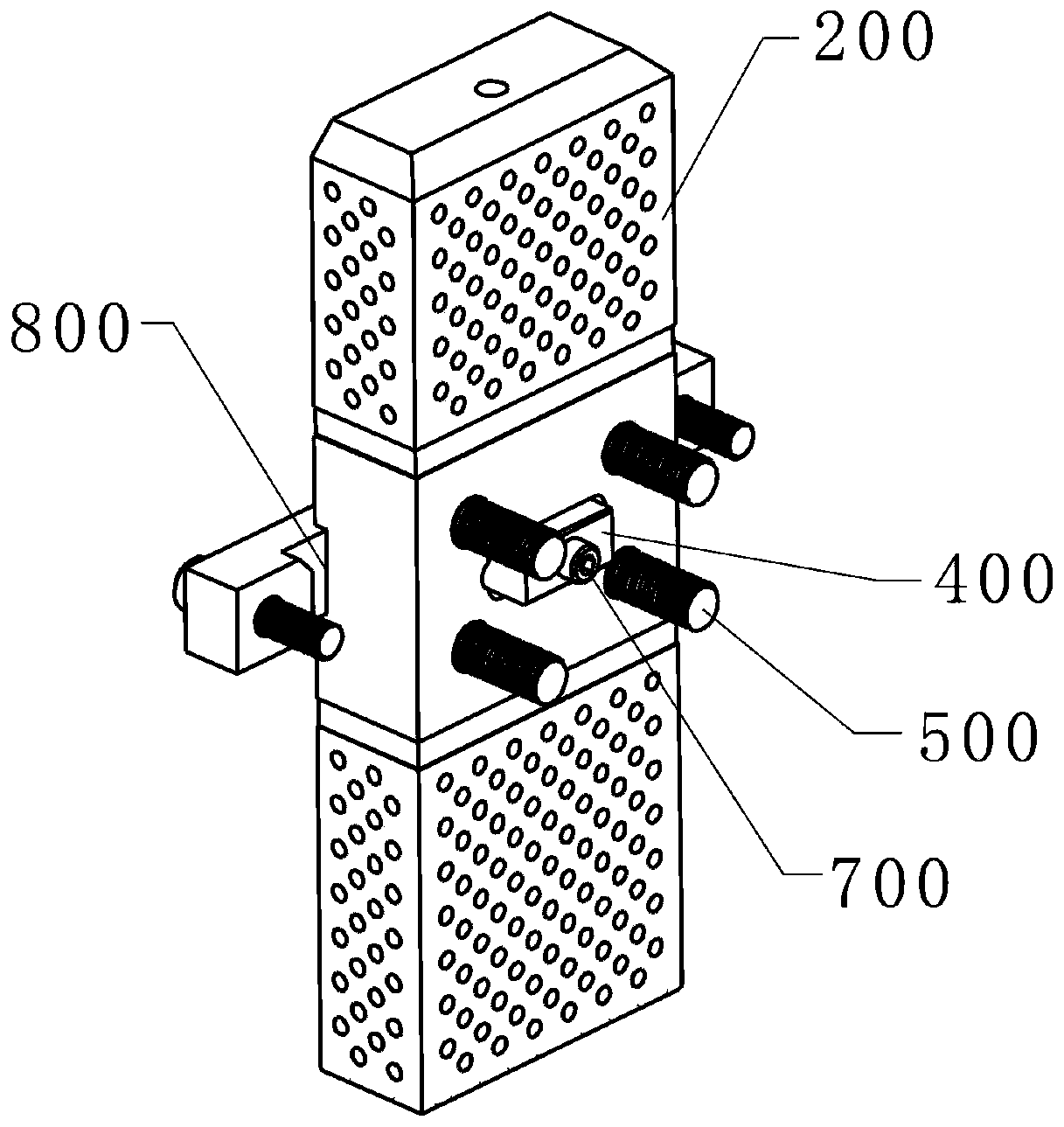

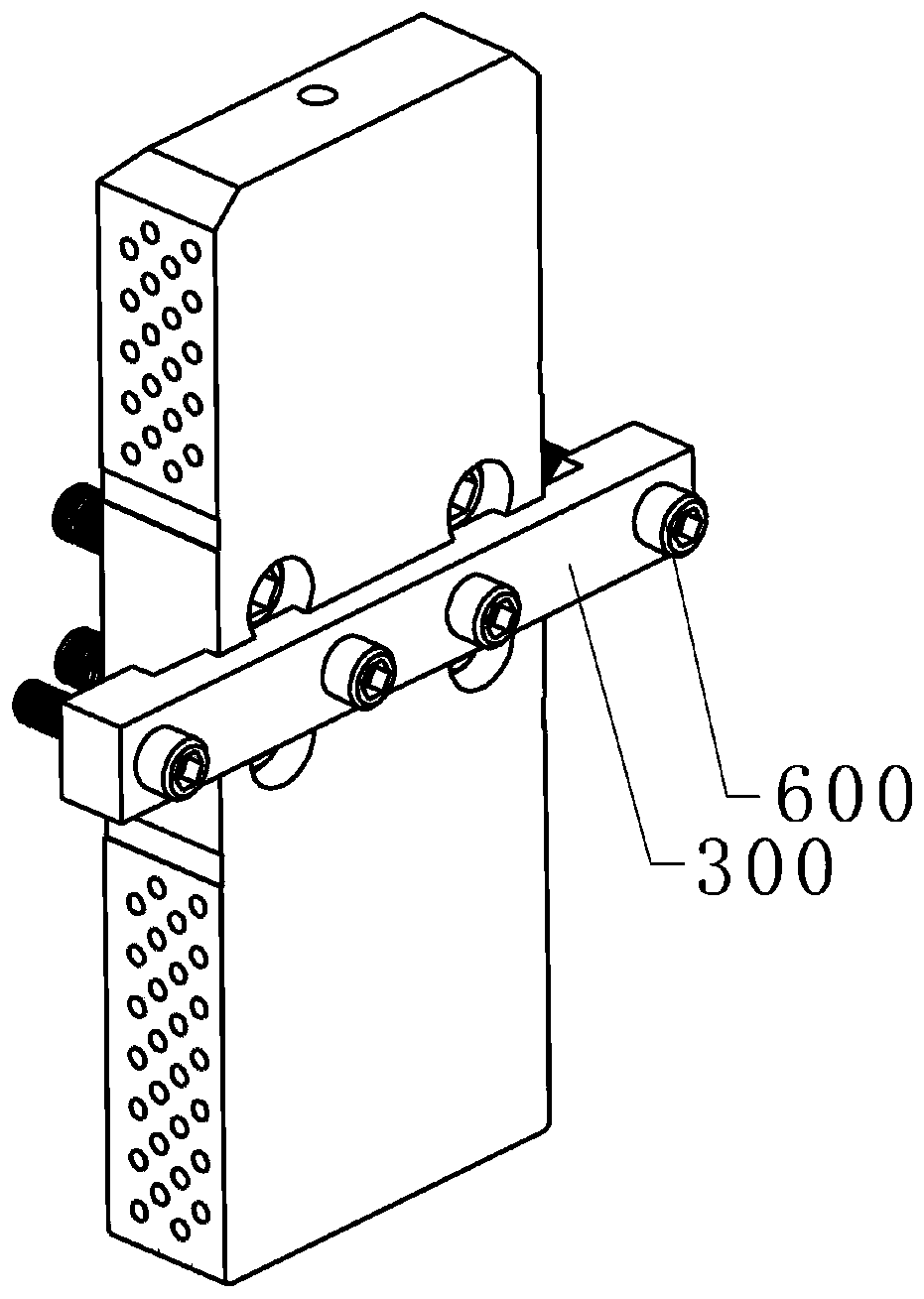

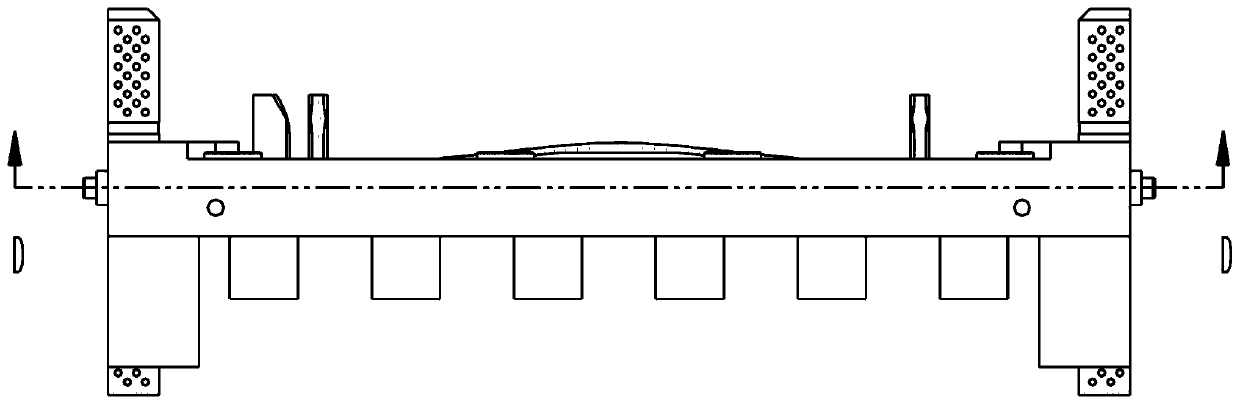

[0051] The following is based on Figure 1-6 A locking structure of a two-way plug-in guide plate according to an embodiment of the present invention is described in detail.

[0052] like Figure 1-6 As shown, the embodiment of the present invention discloses a locking structure of a two-way plug-in guide plate, including: an assembly base 100 located between the upper and lower mold bases, and two-way plug-in guide plates 200 and locking plates fixed on both sides of the assembly base 100 300; the following will introduce one side of the assembly base 100 as an example.

[0053] In the embodiment of the present invention, a guide plate positioning key 400 is provided between the two-way plug-in guide plate 200 and the assembly base 100 .

[0054] Specifically, the two-way plug-in guide plate 200 is provided with a guide plate keyway 201 processed by NC, and the assembly base 100 is provided with an assembly base keyway 101 processed by NC; one end of the guide plate positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com