Ejector pin exhausting structure

A technology of thimble and exhaust groove, which is applied in the field of molds, can solve the problems of time-consuming and labor-intensive thimble processing, melt blockage and other problems, and achieve the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

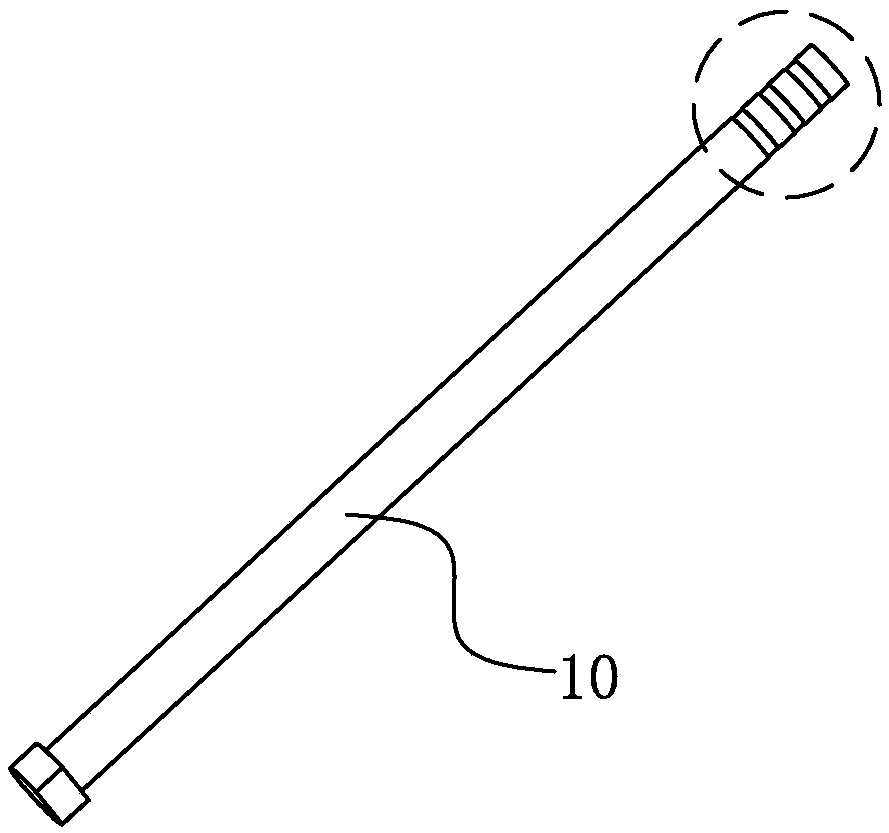

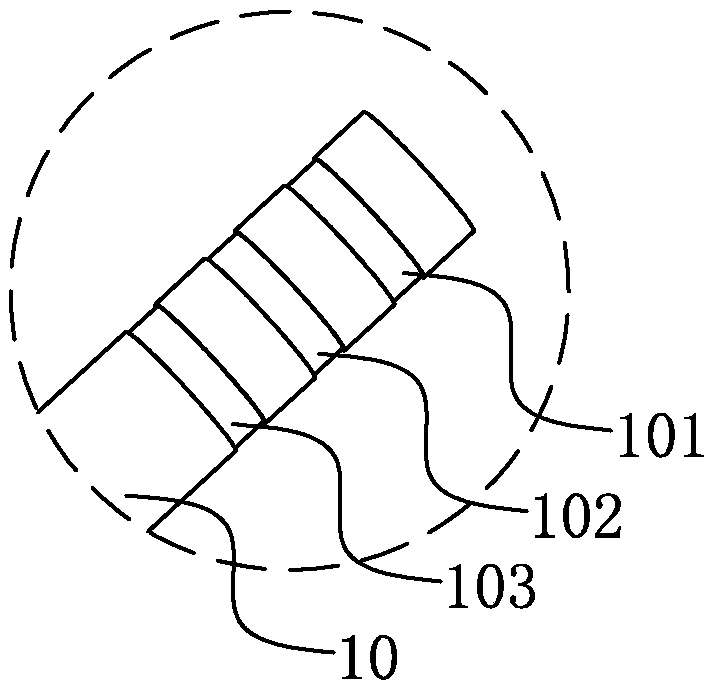

[0018] see figure 1 and figure 2 shown, where figure 1 It is a structural schematic diagram of the thimble exhaust structure of the present invention, figure 2 It is a partially enlarged schematic diagram of the thimble exhaust structure of the present invention.

[0019] The thimble exhaust structure of the present invention includes:

[0020] The thimble body 10 is provided with several exhaust grooves at its upper end, each exhaust groove is spaced with the same length, and the depth of all exhaust grooves is equal;

[0021] There is a certain distance between the top of the thimble body 10 and the nearest exhaust groove 101 below, so that the exhaust groove will not be too close to the casting and be blocked by molten soup, and the exhaust effect can be achieved.

[0022] Optionally, the width of the exhaust grooves 102 is 3 mm, and the depth is 0.2 mm; if the exhaust volume is too large during the molding process, the width of the exhaust grooves can be increased. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com