Soldering device for electronic product production

A technology for electronic products and soldering, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve problems such as low efficiency, achieve better use effect, improve welding efficiency, and facilitate commutation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

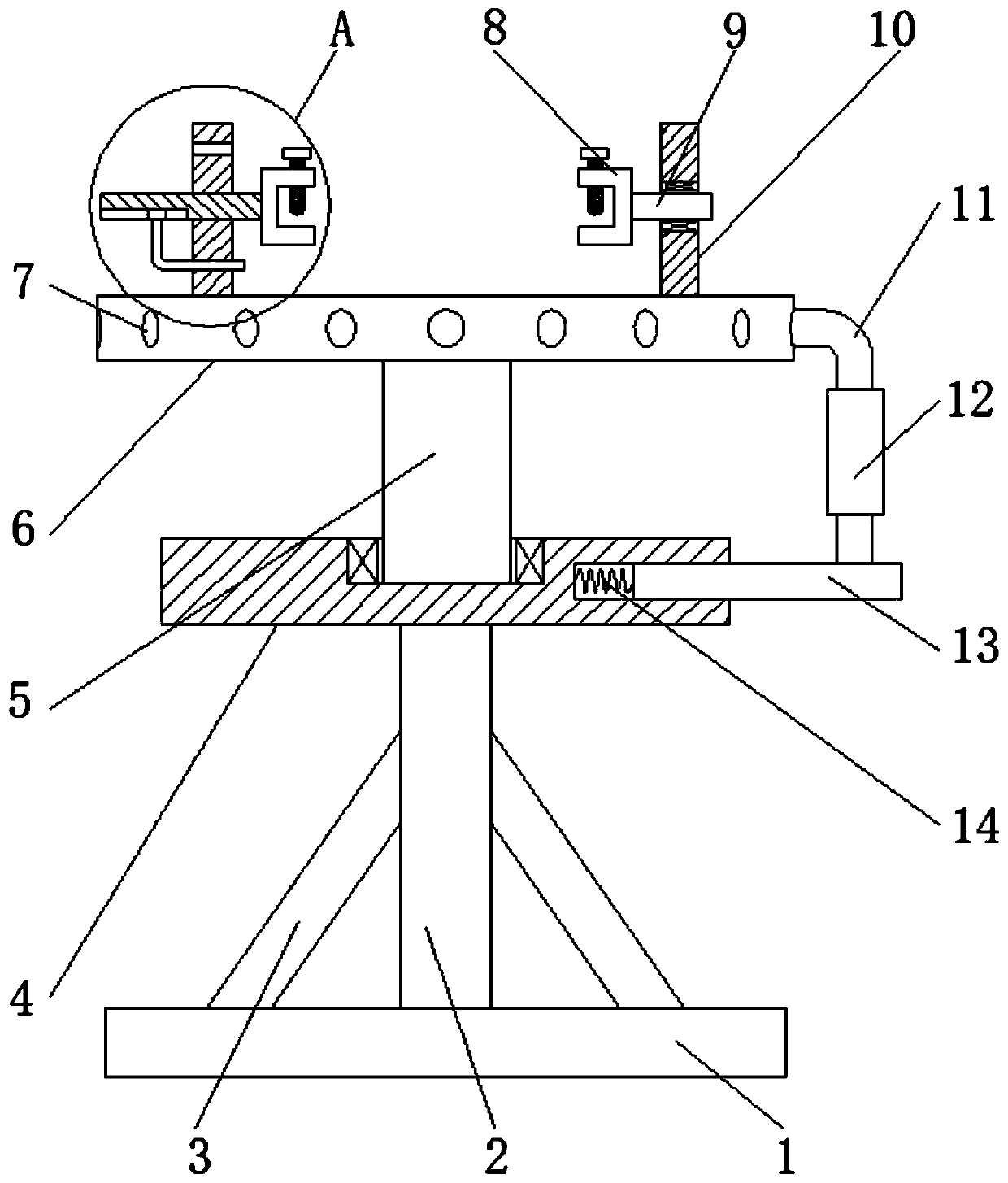

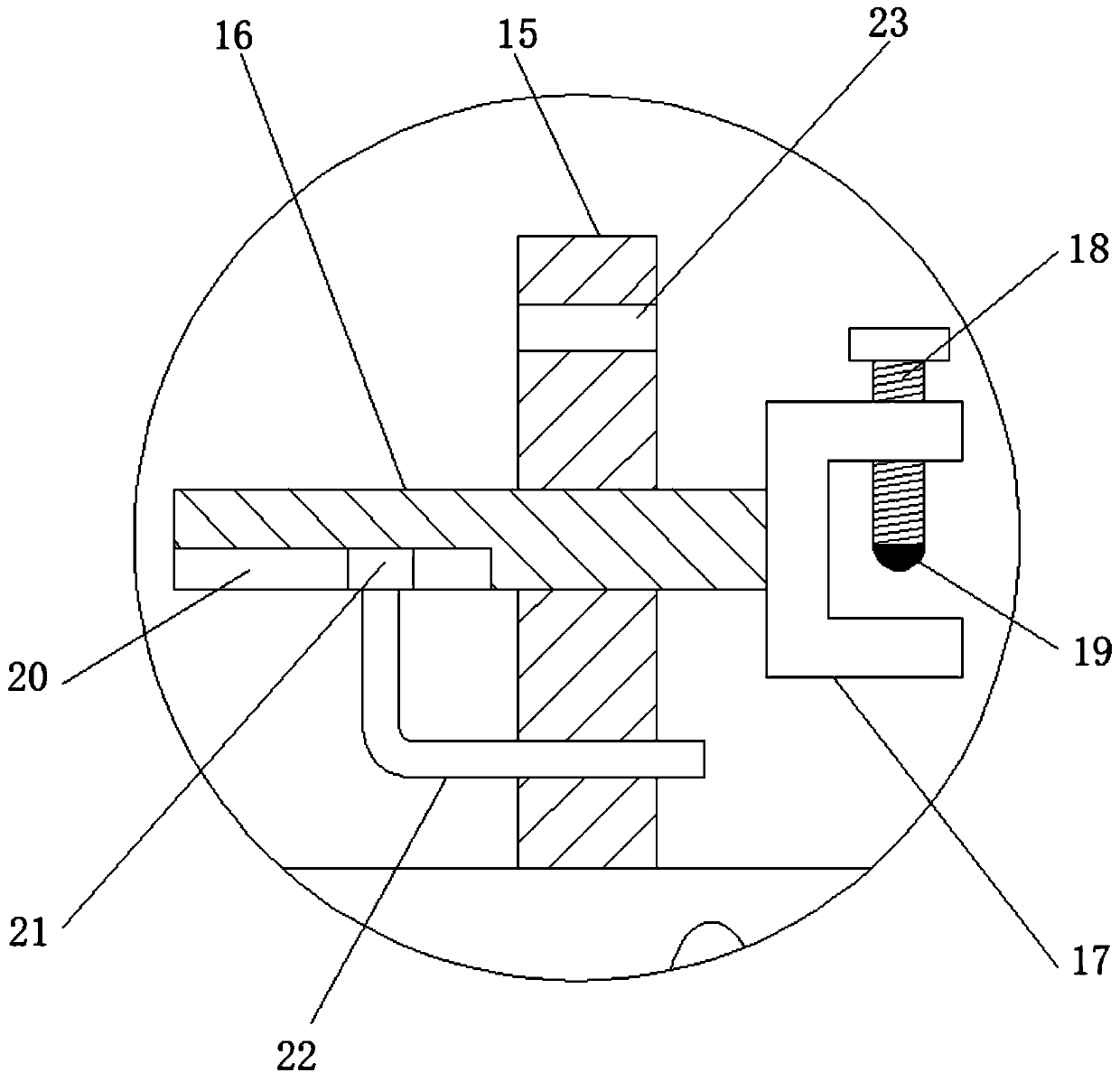

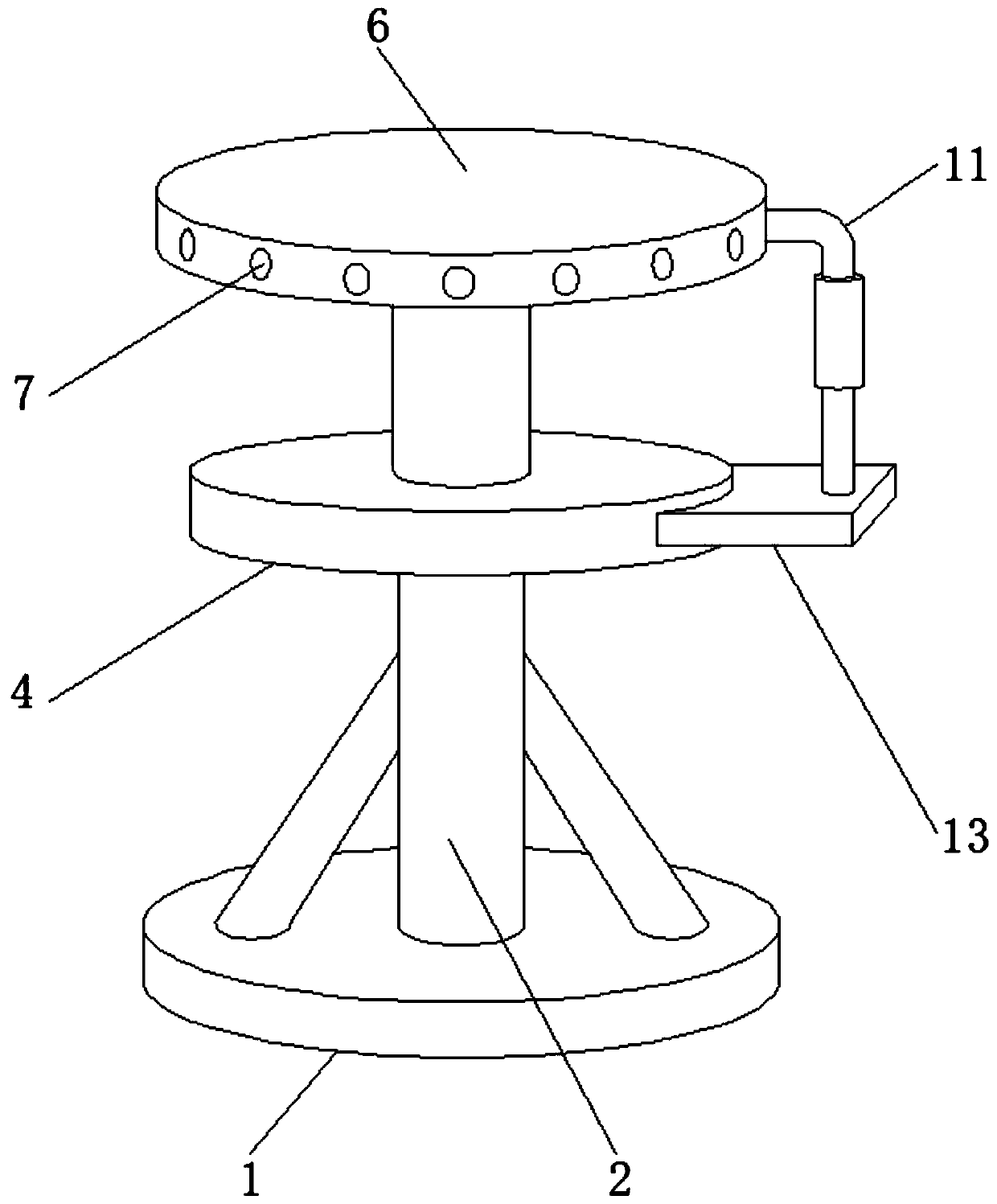

[0029] refer to Figure 1-3 , a soldering device for electronic product production, comprising a base 1, a column 2 is welded on the top outer wall of the base 1, and a fixing plate 4 is welded on the top outer wall of the column 2, and a groove is opened on the top outer wall of the fixing plate 4, and the concave The inner wall of the groove is connected with the rotating shaft 5 through bearing rotation, the top outer wall of the rotating shaft 5 is welded with the turntable 6, the position near the side of the top outer wall of the turntable 6 is welded with the first vertical plate 10, and one side outer wall of the first vertical plate 10 has a Mounting port, the inwall of mounting port is connected with rotating rod 9 through bearing rotation, and the outer wall of one end of rotating rod 9 is welded with right clip frame 8, the top outer wall of rotating disk 6 is welded with second vertical plate 15, and the second vertical plate 15 One side outer wall has fixed mouth...

Embodiment 2

[0033] refer to Figure 4, a soldering device for electronic product production. Compared with Embodiment 1, this embodiment also includes a side plate 24 welded to the outer wall of one side of the fixed plate 4, and the top outer wall of the side plate 24 is connected with an exhaust fan 25 by bolts. One side outer wall of exhaust fan 25 is provided with exhaust pipe 26, and the top outer wall of air extractor 25 is welded with exhaust pipe 27, and the outer wall of one end of exhaust pipe 27 is welded with exhaust hood 28, and the top outer wall of side plate 24 is welded with Support bar 29, and the top outer wall of support bar 29 and the bottom outer wall of suction pipe 27 are welded, exhaust fan 25 is connected with switch by wire, and switch is connected with power supply by wire.

[0034] Working principle: When in use, the exhaust fan 28 is driven to work, and the welding fume generated by welding can be absorbed through the exhaust hood 28, and then discharged thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com