Paper folding machine for filter paper of filter

A technology of origami machine and filter, which is applied in the direction of cardboard items, etc., can solve the problems of poor filter paper quality, etc., and achieve the effect of good product quality and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

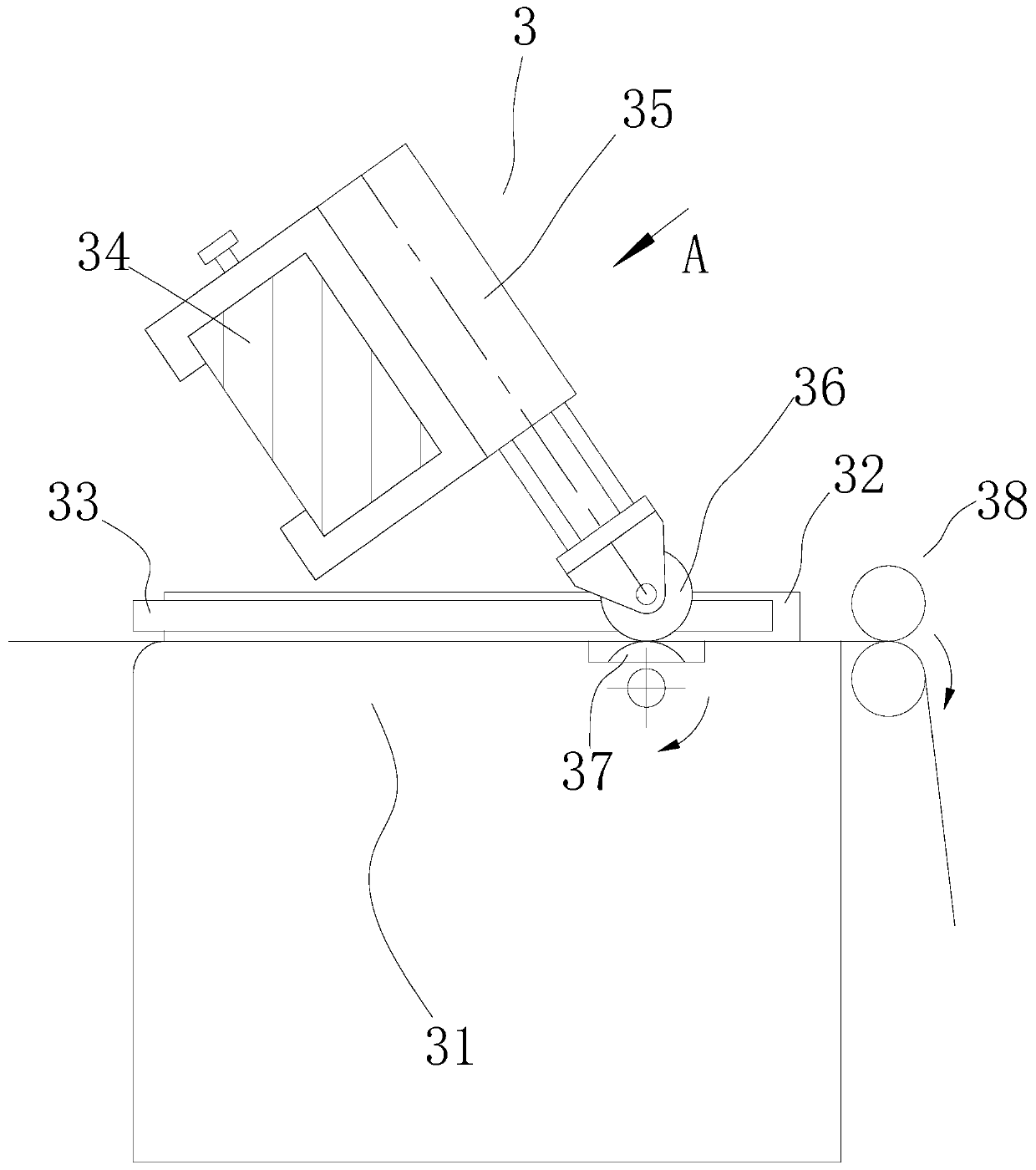

[0040] Such as Figure 8 , 9 As shown, a filter paper folding machine includes a fourth platform 51 arranged on the frame 1, the filter paper 21 to be folded passes through the upper surface of the fourth platform 51, and the two sides of the filter paper 21 on the fourth platform 51 are arranged The third lateral limiting strip 52, the third lateral limiting strip 52 has the same function and structure as the first lateral limiting strip 32. Specifically, the fourth platform 51 is provided with a The long hole in the moving direction, the third lateral limit bar 52 is installed in the long hole through bolts and nuts.

[0041] A third guide plate 53 along the moving direction of the filter paper 21 is arranged above the filter paper 21, a fifth platform 54 is arranged behind the fourth platform 51, a pressing plate 55 is arranged above the fifth platform 54, and an upper folding assembly 56 is arranged above the pressing plate 55 , a lower folding assembly 57 is disposed be...

Embodiment 2

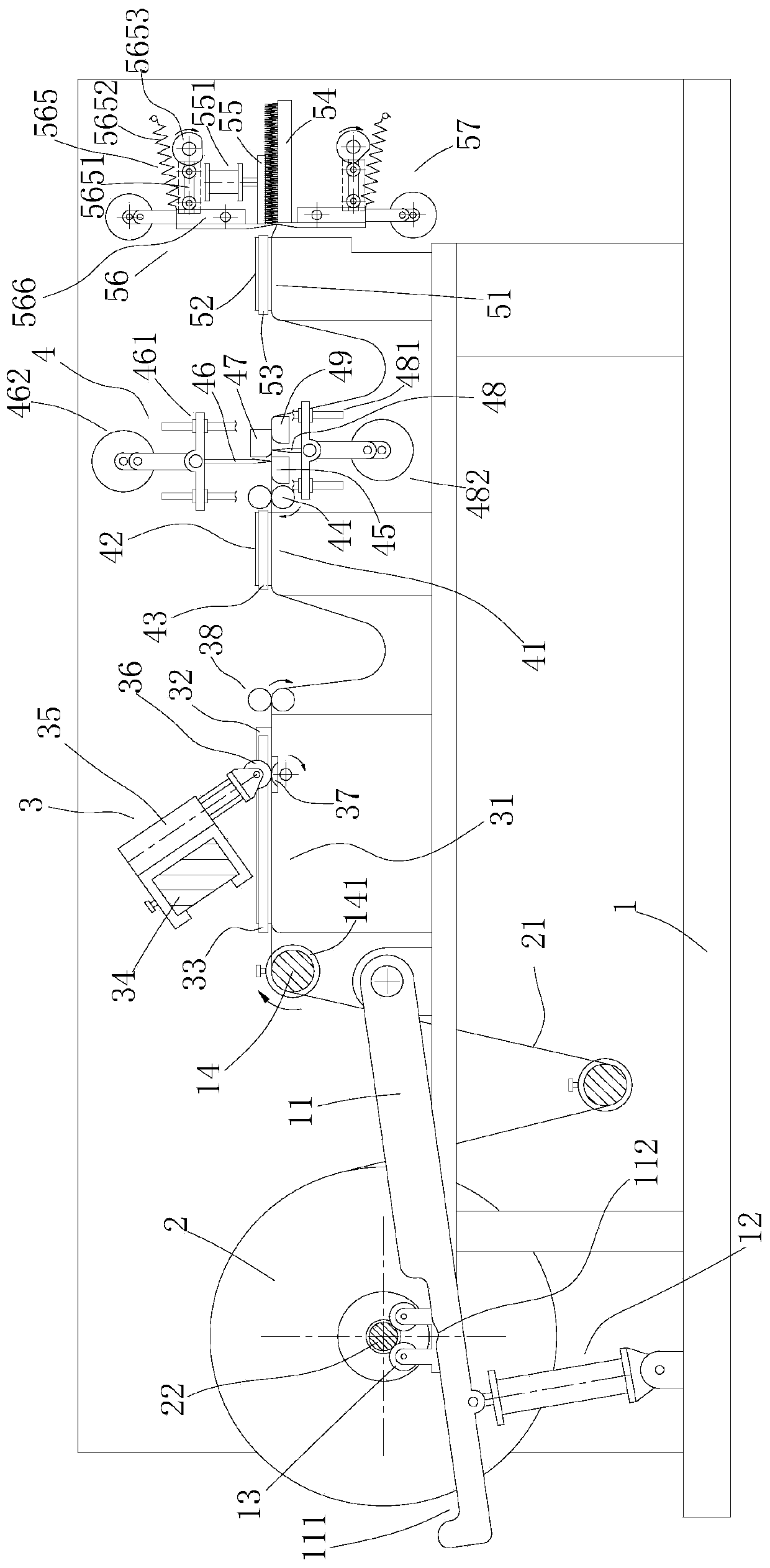

[0051] Such as figure 1 As shown, it also includes a frame 1, a filter paper roll 2, a longitudinal creasing mechanism 3, and a transverse creasing mechanism 4.

[0052] Such as figure 1 , 2 As shown, the filter paper roll 2 is rotatably arranged on the frame 1, with the transmission direction of the filter paper 21 drawn from the filter paper roll 2 as the rear, the rear of the filter paper roll 2 is sequentially provided with a longitudinal creasing mechanism 3 and a transverse creasing mechanism. 4.

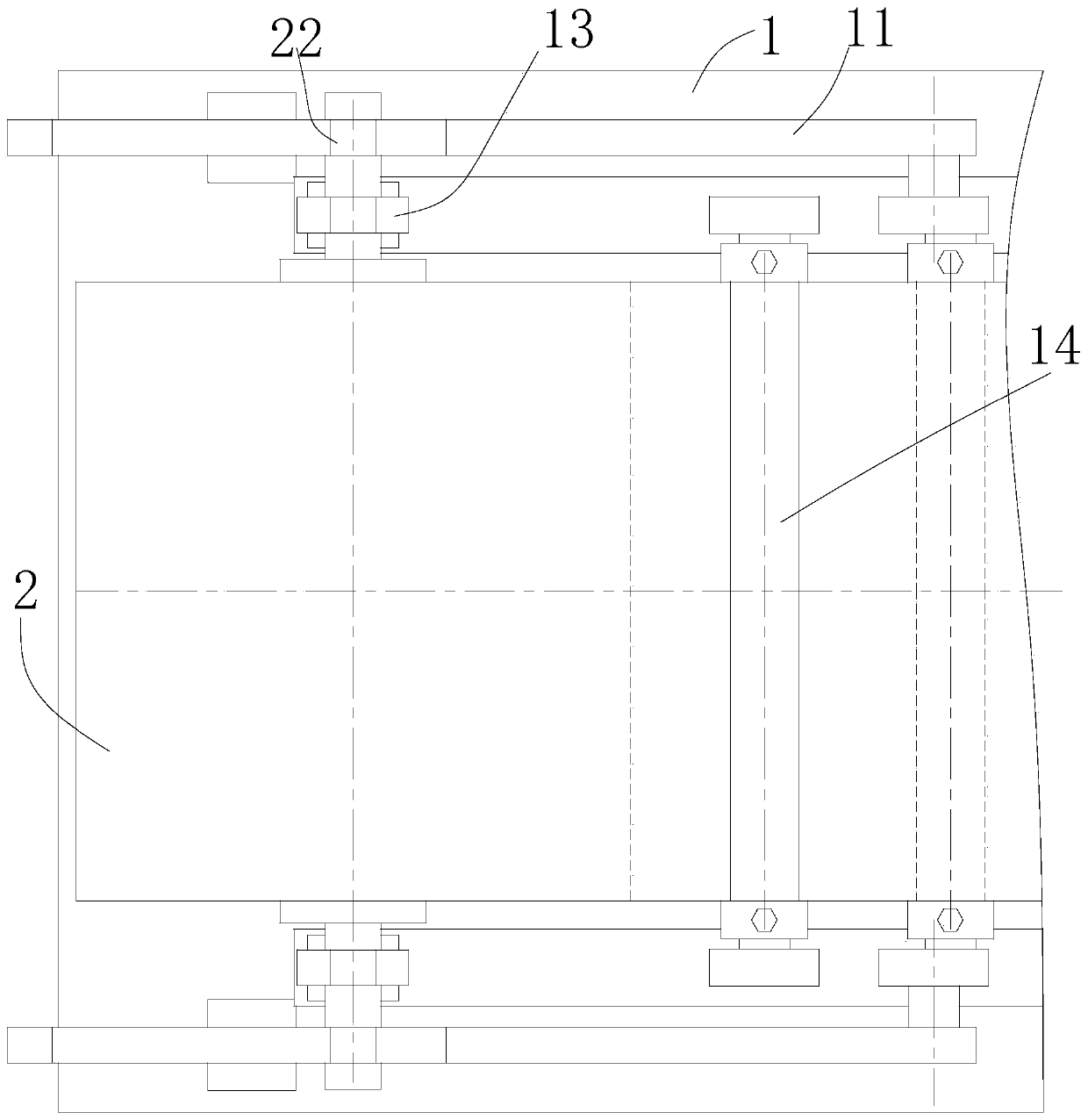

[0053] Such as figure 1 , 2 As shown, the filter paper roll 2 includes a support shaft 22, the support shaft 22 is wound with a filter paper 21, the frame 1 is hingedly provided with a bracket 11, the bracket 11 is located on both sides of the filter paper roll 2, and the bracket 11 is located on the Below the support shaft 22, the bracket 11 is provided with a first gap 111 for placing the support shaft 22, the hinged position of the bracket 11 is located behind the supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap