A kind of preparation method of composite metal oxide functional electrode

A composite metal and oxide technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve problems such as limited loading of cobalt tetroxide, loss of precious metals, complicated preparation steps, etc., and achieve efficient realization Reduction removal, low concentration of intermediate by-products, and broad engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing a composite metal oxide functional electrode, which includes:

[0034] (1) Carbon cloth base pretreatment:

[0035] First, cut out a carbon cloth with a size of 2×2 cm, and then perform ultrasonic cleaning on it with acetone and absolute ethanol to remove surface stains. The ultrasonic cleaning time is 30 minutes, and the power is 90W; the cleaned carbon cloth is rinsed with deionized water 3 times to remove residual acetone and absolute ethanol on the surface; then soak the carbon cloth in 3mol / L nitric acid solution for 12 hours to remove impurities such as inorganic oxides on the surface of the carbon cloth, and then rinse it with deionized water; finally, the carbon cloth Arranged in a vacuum drying oven, vacuum-dry at 60°C for 12 hours, and the vacuum degree is -0.1MPa;

[0036] (2) Co(OH) used in the preparation of functional electrodes 2 / Cu(OH) 2 Precursor preparation:

[0037] ①Chemical raw materials used:

...

Embodiment 2

[0058] This embodiment provides a method for preparing a composite metal oxide functional electrode, which includes:

[0059] (1) Carbon cloth base pretreatment:

[0060] First, cut out a carbon cloth with a size of 2×2 cm, and then perform ultrasonic cleaning on it with acetone and absolute ethanol to remove surface stains. The ultrasonic cleaning time is 40 minutes, and the power is 90W; the cleaned carbon cloth is rinsed with deionized water 3 times to remove residual acetone and absolute ethanol on the surface; then soak the carbon cloth in 3mol / L nitric acid solution for 12 hours to remove impurities such as inorganic oxides on the surface of the carbon cloth, and then rinse it with deionized water; finally, the carbon cloth Arranged in a vacuum drying oven, vacuum-dry at 65°C for 12 hours, and the vacuum degree is -0.1MPa;

[0061] (2) Co(OH) used in the preparation of functional electrodes 2 / Cu(OH) 2 Precursor preparation:

[0062] ①Chemical raw materials used:

...

experiment example

[0075] Experimental procedure is basically consistent with embodiment 1, and difference is:

[0076] (1) The concentration of nitrate nitrogen in the electrolyte solution is 50mg / L, the concentration of sodium sulfate is 0.1g / L, and the concentration of sodium chloride is 2g / L.

[0077] (2) When using the constant current mode to reduce the nitrate in the solution, the cathode current is controlled at 0.08A, and the reduction treatment time is 180min.

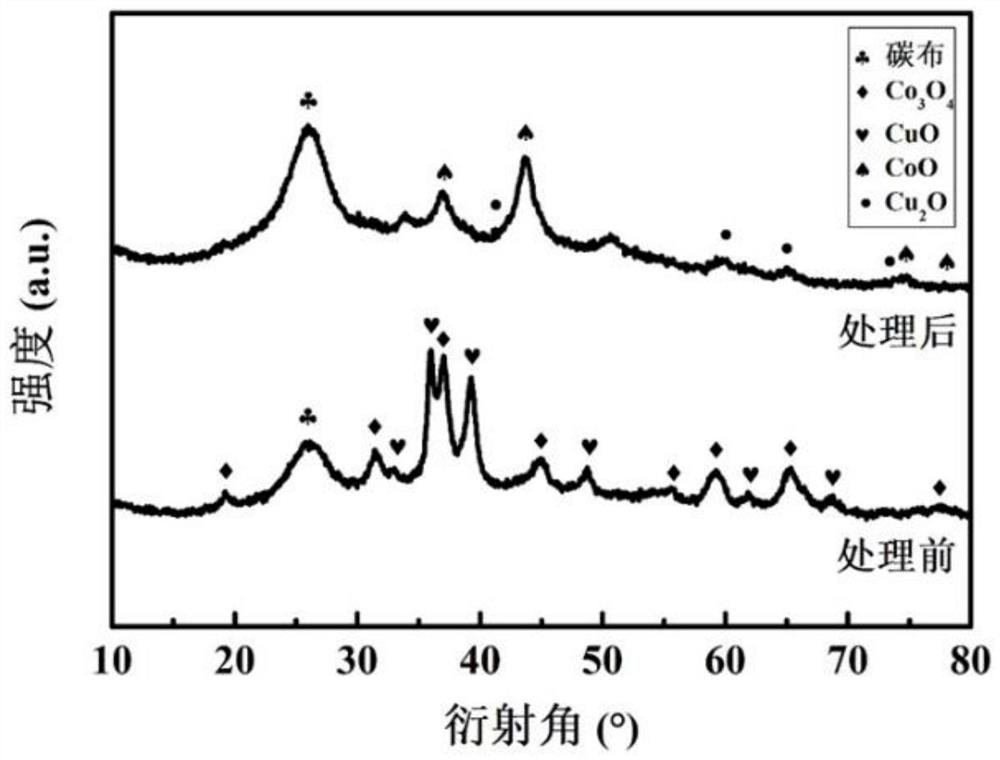

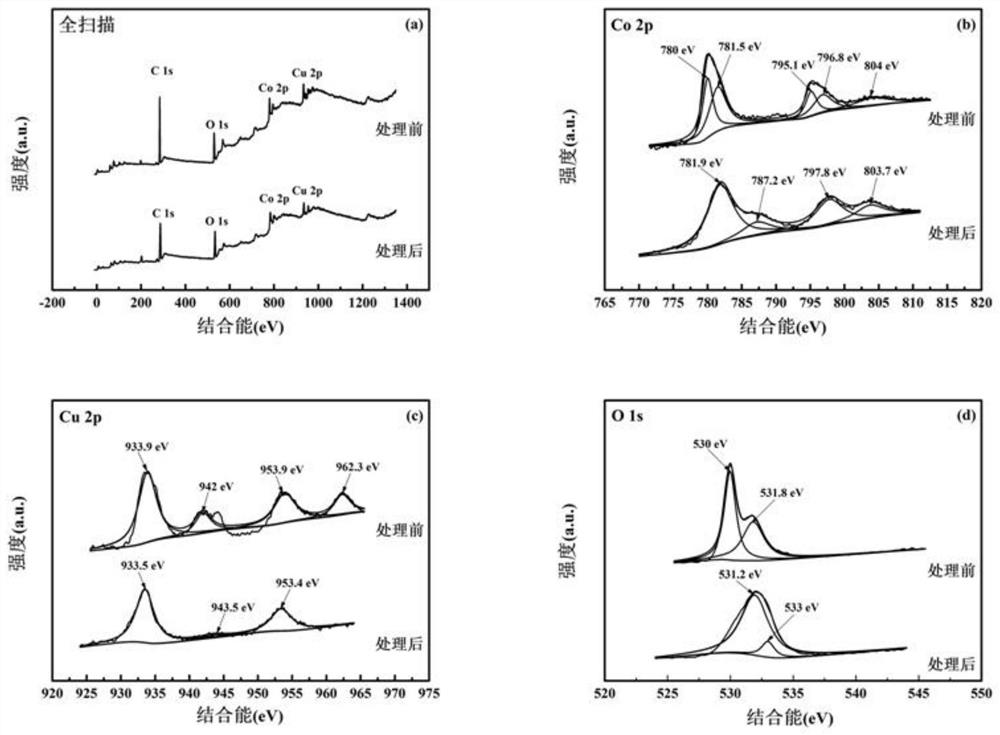

[0078] Experimental results: Figure 5 Be CoO / Cu in embodiment 2 2 O functional electrode, Cu 2 Nitrate removal rate and product concentration diagram of O electrode and CoO electrode, CoO / Cu 2 The removal rate of nitrate by O functional electrode is 91.4%, and its performance on nitrate removal is better than that of CoO electrode, Cu 2 O electrode, during the reaction process, the concentration of intermediate products nitrite and ammonium salt first increases and then decreases, and finally decreases to 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com