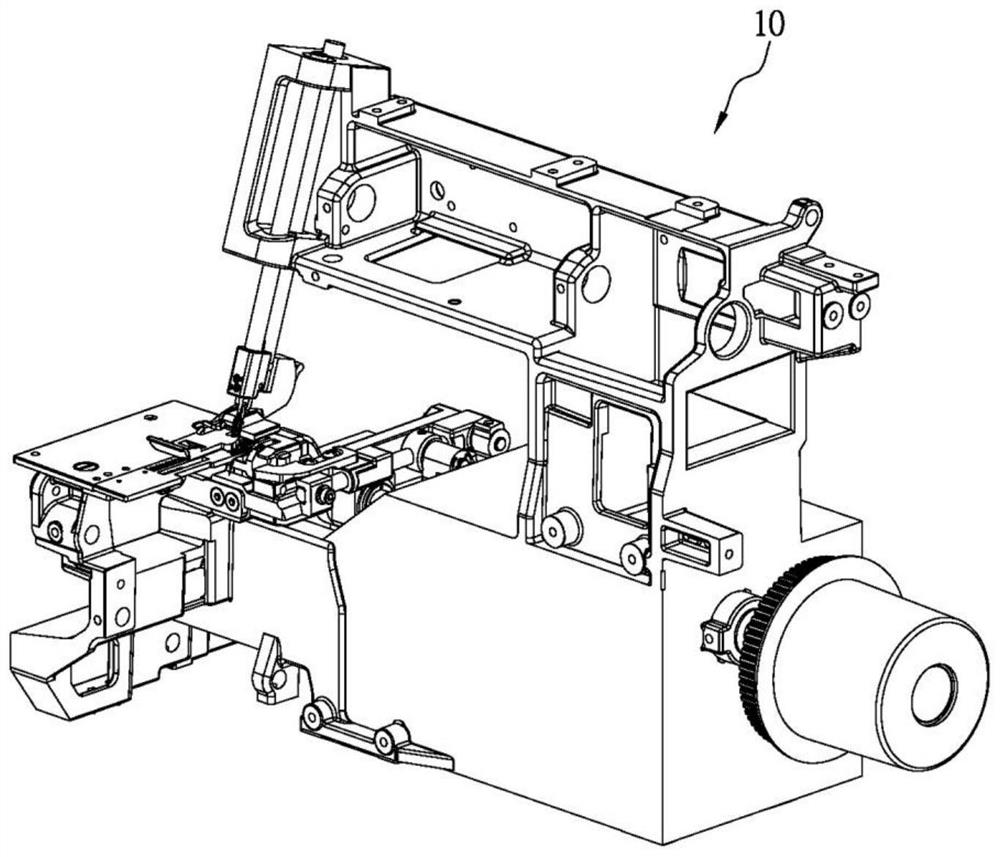

Stable Mechanism of Feed Dogs of Sewing Machine

A technology of feeding teeth and sewing machines, applied in the direction of feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problem that the pressing displacement of the feeding teeth and the cloth feet cannot reliably bite the cloth and achieve the effect of maintaining the feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

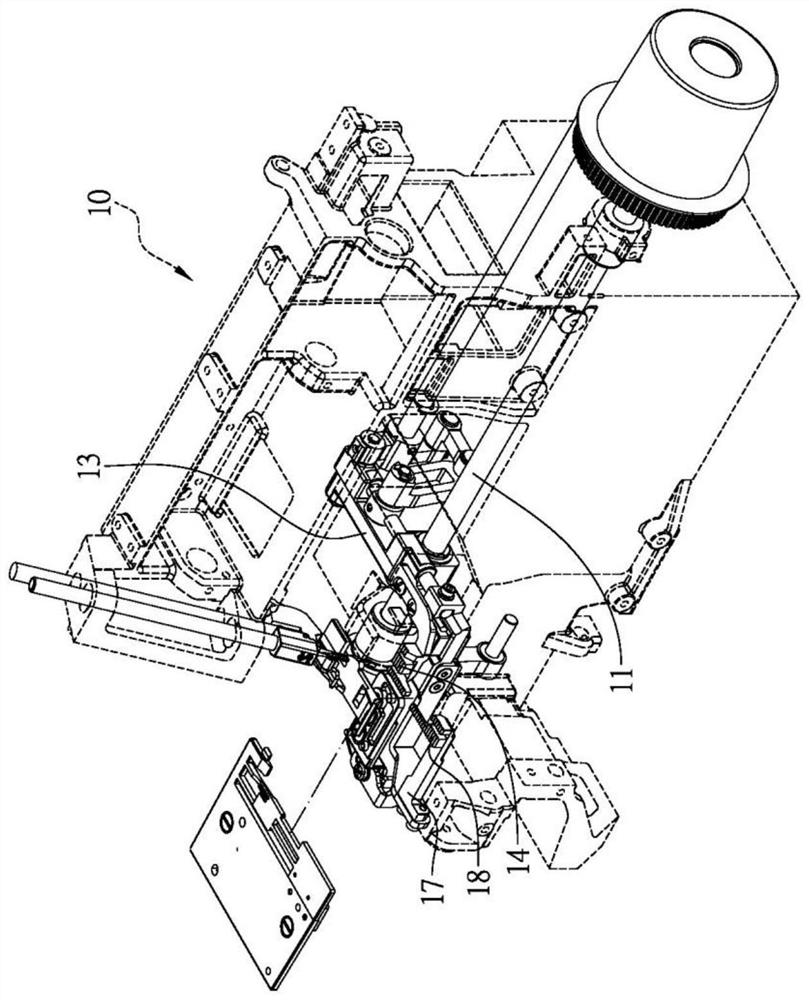

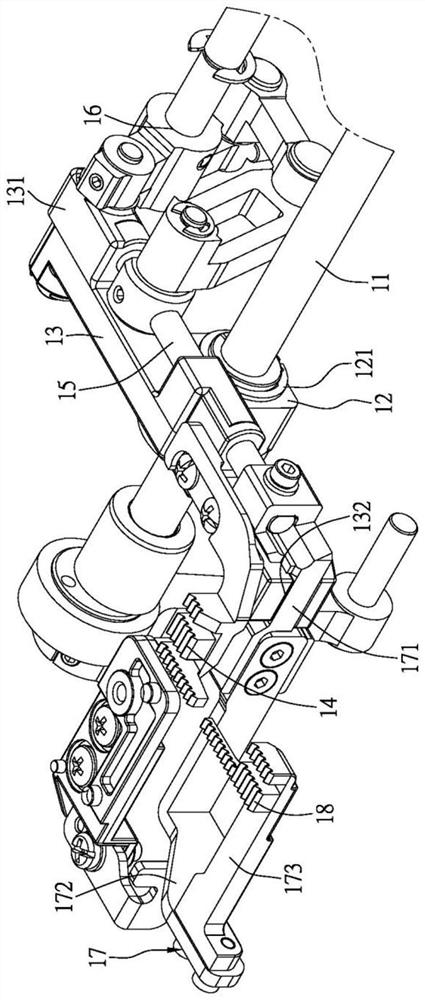

[0080] see Figure 4 and Figure 5 , the present invention is a feed dog stabilizing mechanism of a sewing machine, comprising:

[0081] A sewing machine 20 has a body 21, which has a pivotable main shaft 22 inside the main body 21, and one end of the main shaft 22 protrudes from the main body 21 for combining power, and a seat 23 is arranged on the main shaft 22, and The extension direction of the main shaft 22 is defined as a first direction Z, and perpendicular to the first direction Z can further define a second direction X and a vertical direction Y that are perpendicular to each other. The main body 21 is provided with a pair of feeding teeth platform 24, the sub-feed dog platform 24 can slide along the second direction X and lean against the seat 23, and one end of the sub-feed dog platform 24 has a clamping groove 241, a threading rod 26 is installed in the auxiliary feeding dog table 24, and one end of the auxiliary feeding dog table 24 is inserted and positioned in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com