Back-light module

A technology for backlight modules and fluorescent tubes, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increasing the cost of inverters, increasing operating voltage and starting voltage, and breakdown of the glass tube wall of fluorescent tubes, and improving efficiency. , Solve the effect of easy deformation, reducing the working voltage and starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further reveal the advantages and spirit of the present invention, a detailed description will be made as follows in conjunction with the drawings.

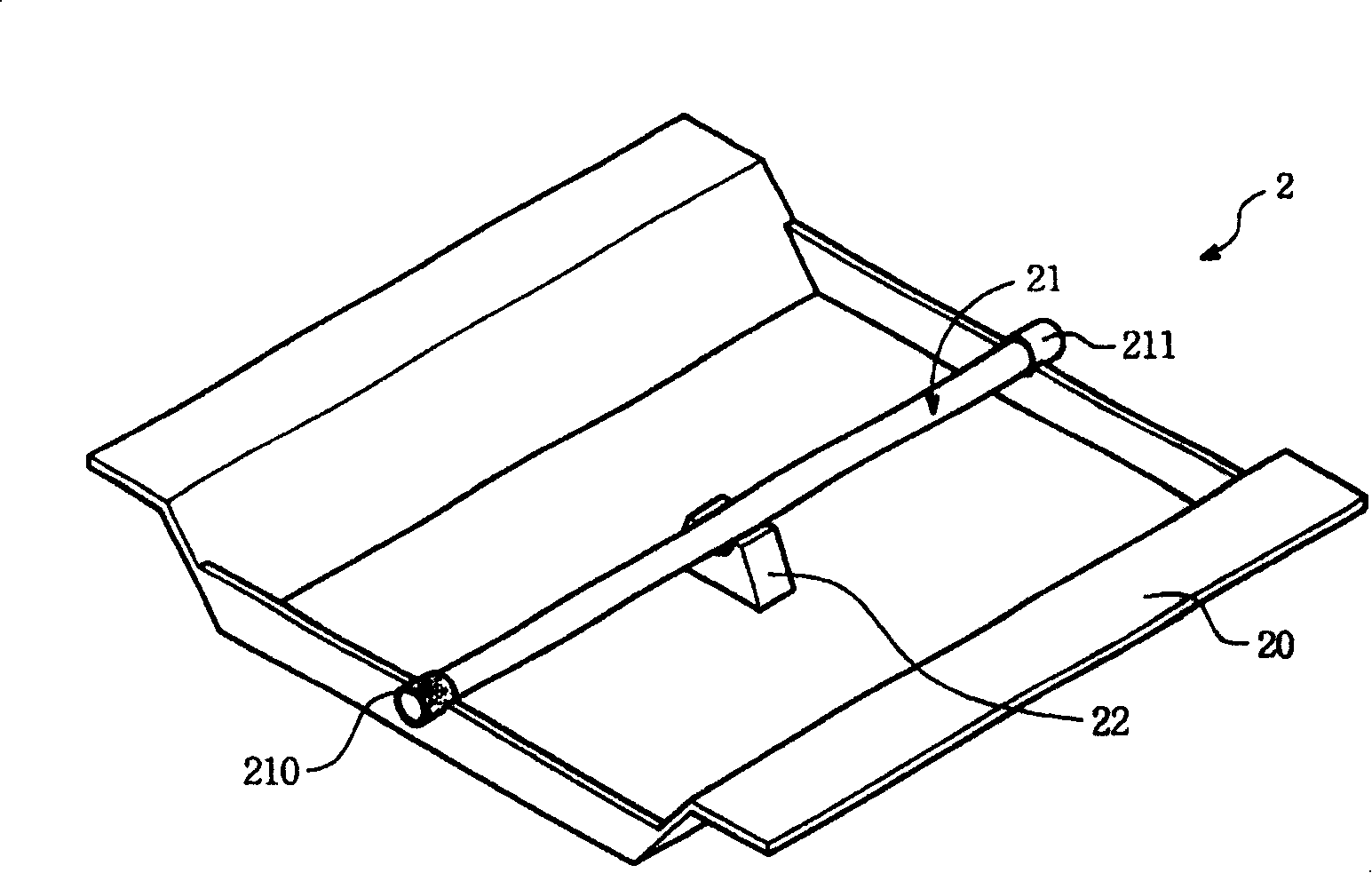

[0051] See Figure 1A , Which is a three-dimensional schematic diagram of the first embodiment of the backlight module disclosed in the present invention.

[0052] The backlight module 2 includes a bottom case 20, a fluorescent tube 21 and a lower bracket 22.

[0053] The fluorescent tube 21, in this embodiment, is an external electrode fluorescent tube, both ends are fixed on the bottom shell, and the outer surface of which is provided with a first electrode 210 and a second electrode 211, which are external electrodes. The first electrode 210 and the second electrode 211 are respectively located at two ends of the fluorescent tube 21.

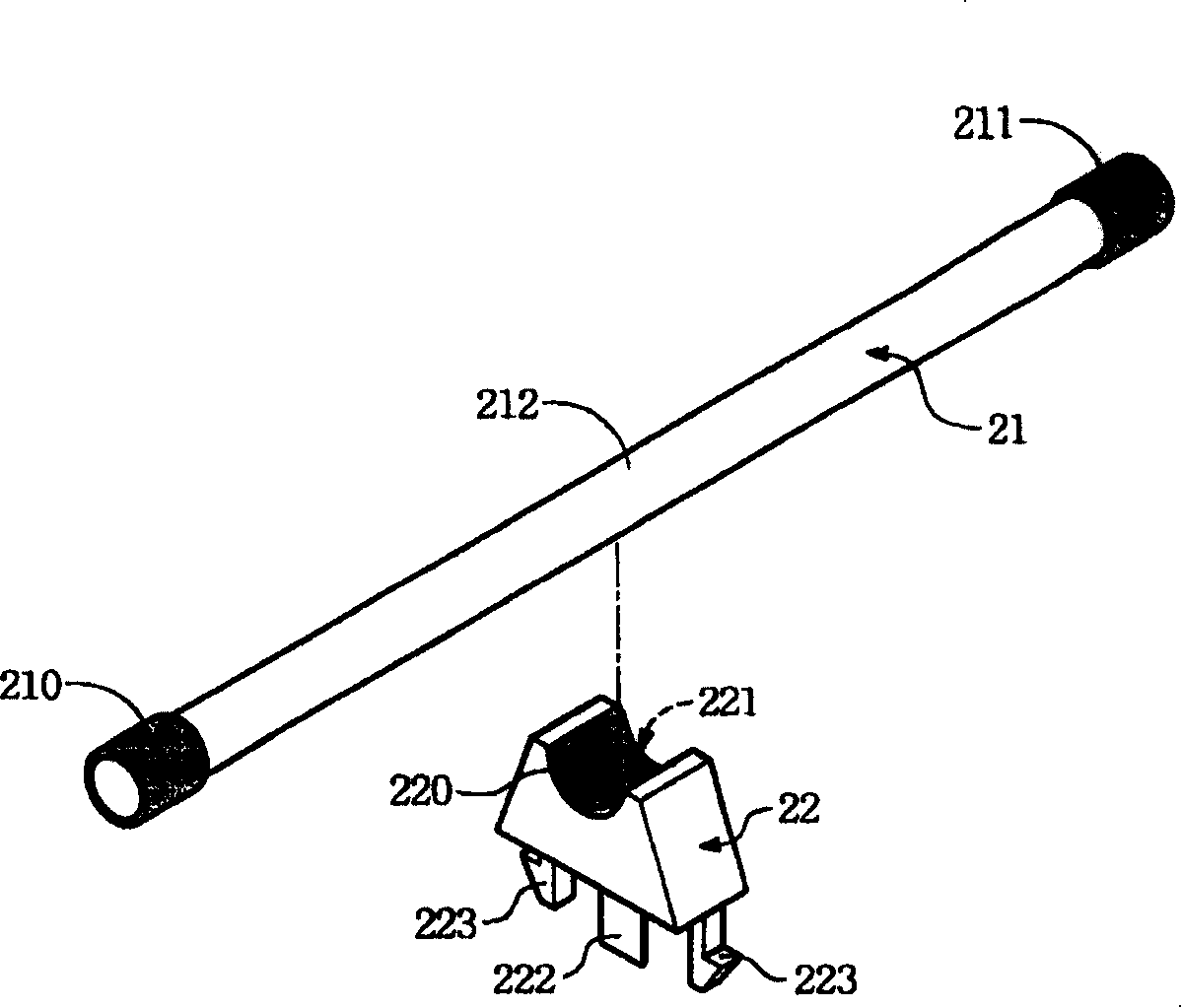

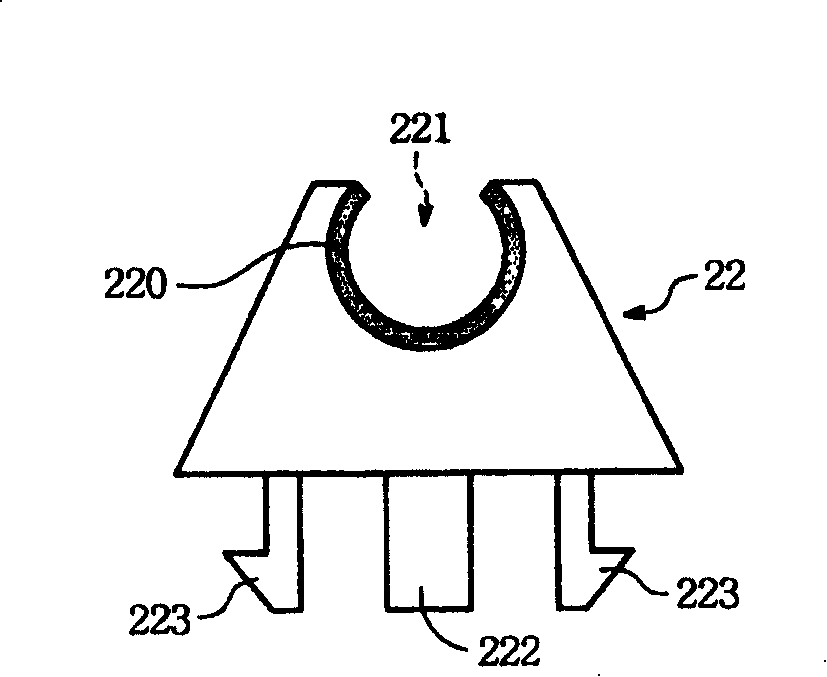

[0054] The lower bracket 22 is fixed on the bottom shell 20. In order to better understand the structure of the lower bracket 22, please refer to it together Figure 1B , Which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com