Soil sampling device for geological exploration

A soil-taking device and geological survey technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of soil sample falling off, soil-taking failure, and low-efficiency soil-taking, so as to increase the success rate and avoid The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

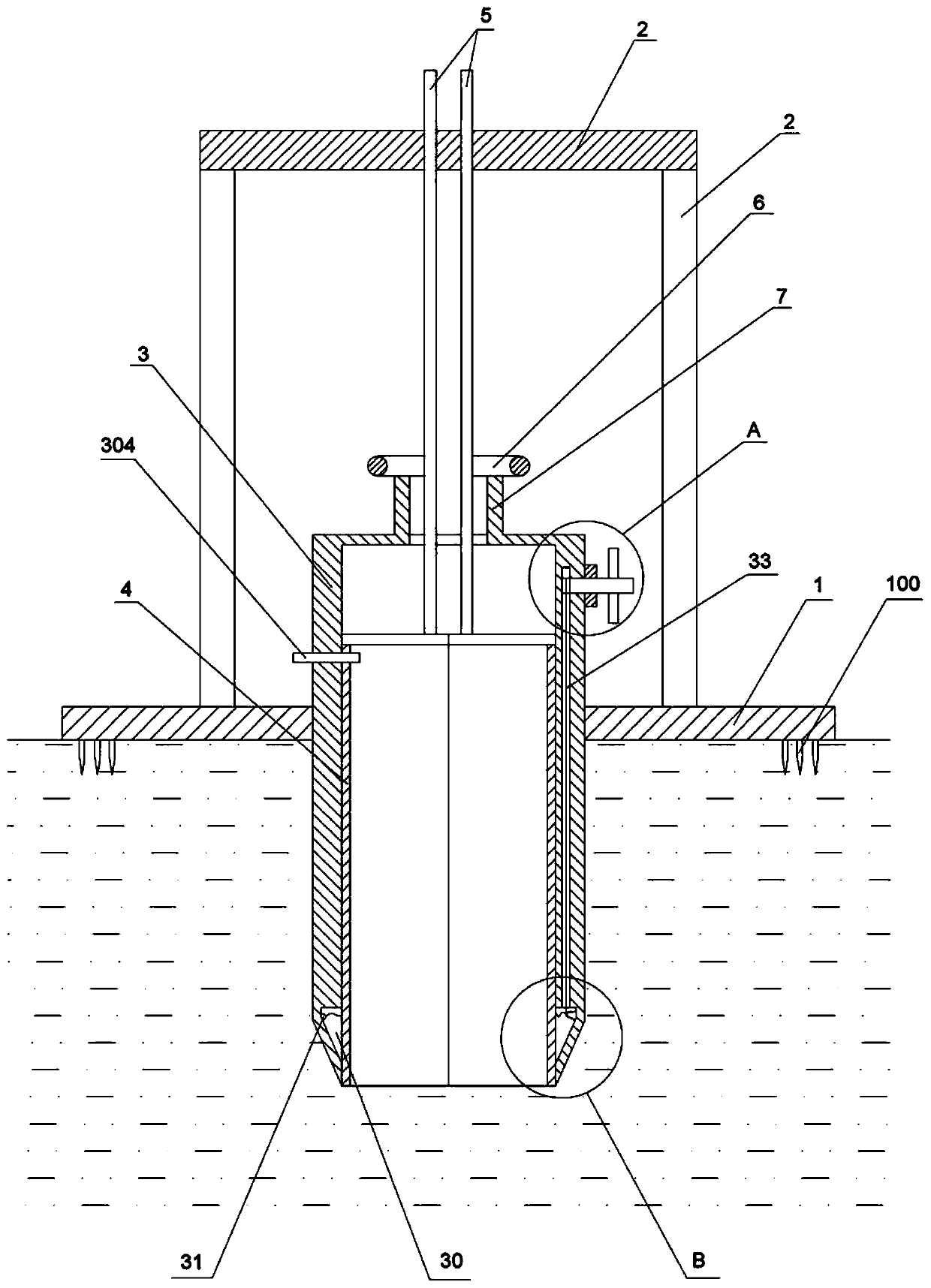

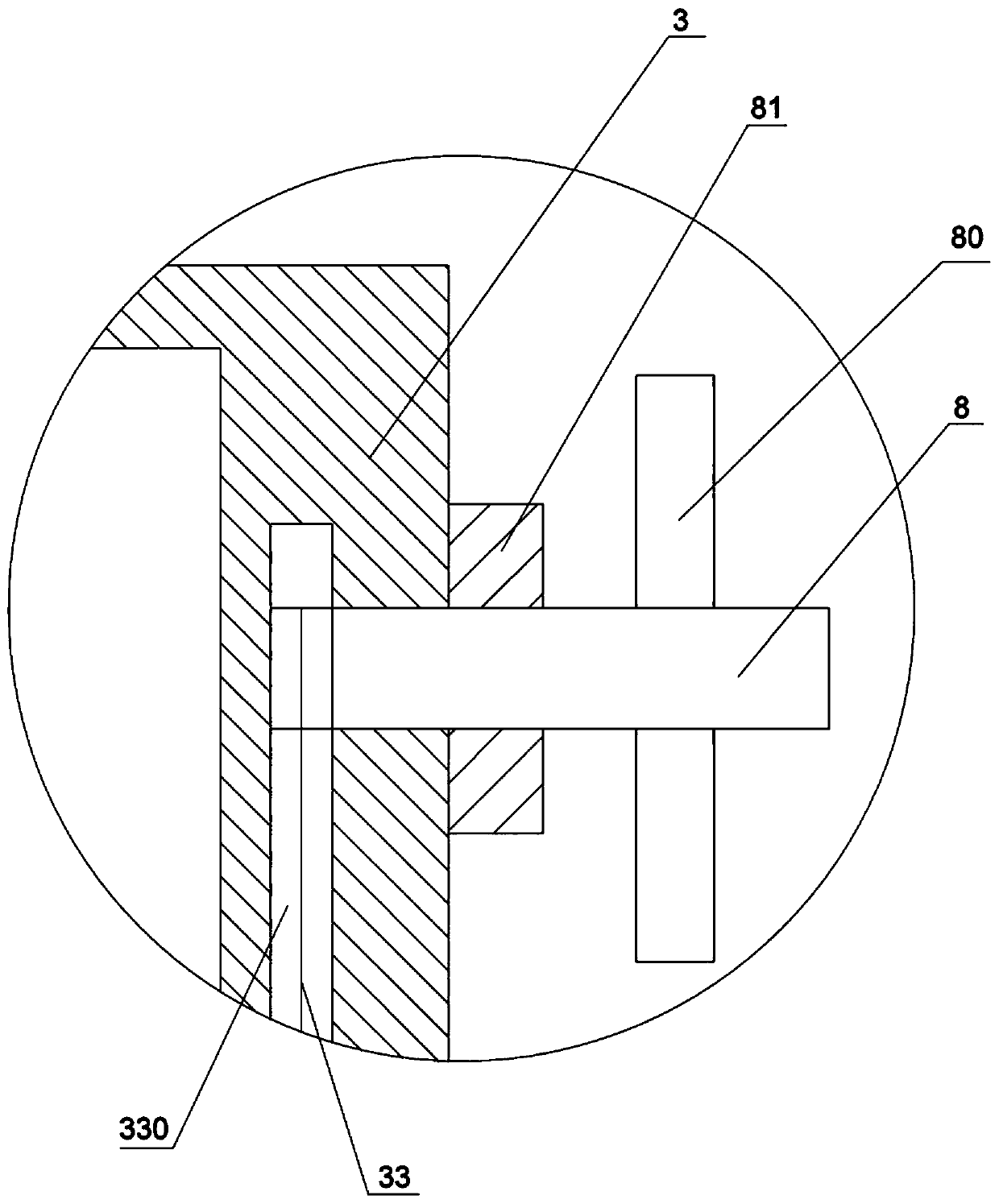

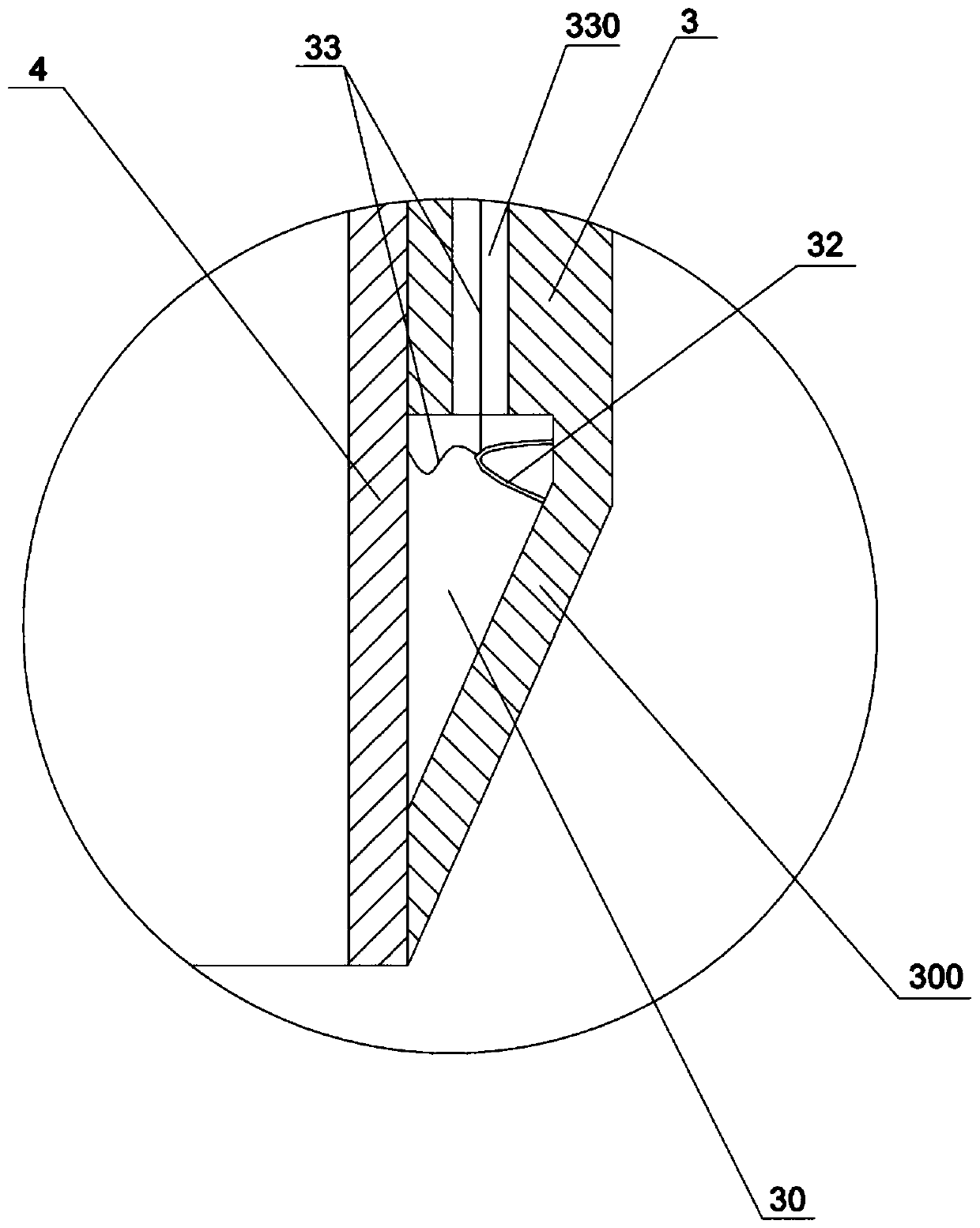

[0028] like figure 1 As shown, a soil-taking device for geological survey in this embodiment includes an inner cylinder 4 and an outer cylinder 3 that are nested in phase, and the tops of the outer cylinder 3 and the inner cylinder 4 are correspondingly provided with through holes, and a through hole is provided in the through hole. The bolt 304 is inserted into the through hole to realize the locking between the outer cylinder 3 and the inner cylinder 4 . There is also a support frame on the outside of the outer cylinder 3. The support frame includes a chassis 1 for fixing on the ground and a frame body 2 fixed on the chassis 1. A round hole is opened on the chassis 1, and the outer cylinder 3 is slidably connected in the round hole. , The bottom of the chassis 1 is also fixed with a claw 100 for inserting into the soil layer. The inner cylinder 4 is spliced by two semi-cylindrical shells, and an anti-rotation rod 5 is integrally formed on the top of the two semi-cylindric...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 lies in: combining Figure 4 Shown, the quantity of soil cutting rope 33 is four in the present embodiment. When the four soil cutting ropes 33 rotate, the cutting effect on the bottom of the soil sample in the inner tube 4 is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com