Electric self-priming lock

A self-priming lock and electric technology, applied in the field of electric locks, can solve problems such as insecurity and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

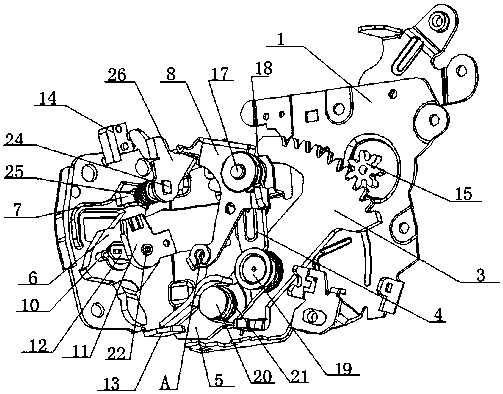

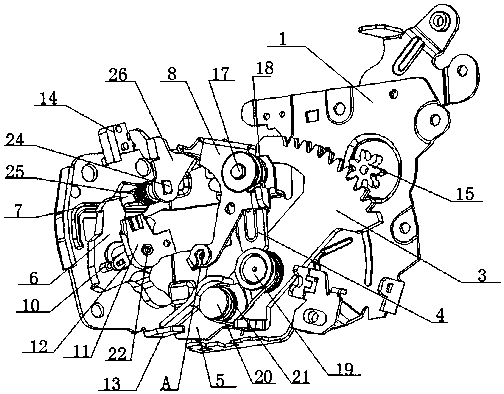

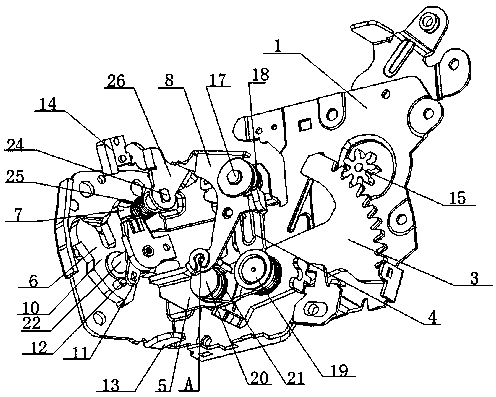

[0023] This embodiment provides an electric self-priming lock, such as Figures 1 to 4 As shown, it is mainly composed of base 1, locking motor, gear plate 3, resisting block 4, toggle lever 5, tiger mouth lock block 6, limit block 7, unlocking piece 8, unlocking motor, controller, rotary switch 11 and The contact switch 14 is composed of a locking motor fixed on the base 1, and its output shaft 15 meshes with one side of the gear plate 3, and the other side of the gear plate 3 is connected to the base through the rotating shaft F 16; one end of the resisting block 4 It is rotatably connected with the base through the rotating shaft A 17 and the first rotating member 18. The first rotating member 18 preferably uses a torsion spring, one end of which is fixedly connected with the resisting block 4, and the other end is fixedly connected with the gear plate 3, and the middle part is wound around the rotating shaft On A 17; before the electric self-priming lock is unlocked, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com