Tunnel groove forming die trolley

A mold trolley and groove technology, which is used in tunnels, tunnel lining, shaft lining, etc., can solve the problems of inconvenient adjustment of the mold trolley and easy damage to the groove, so as to prevent damage, improve stability, and improve consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

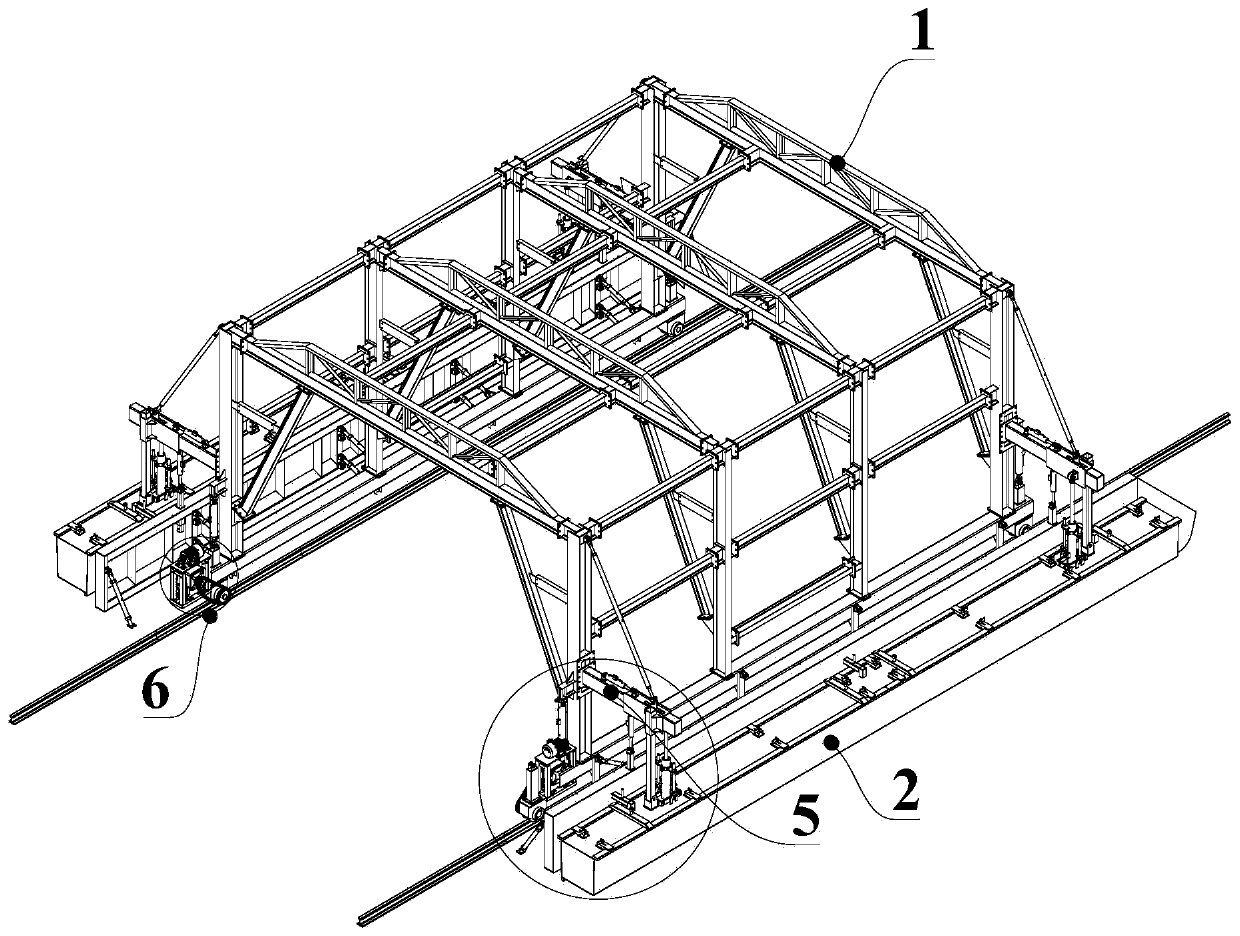

[0024] Such as figure 1 As shown, the present embodiment provides a tunnel groove forming mold trolley, which includes a body 1 spanning both sides of the tunnel. The body 1 is a frame structure with a driving passage (not shown) in the middle. The groove mold 2 and the groove baffle plate 3 between the groove mold 2 and the body 1 are respectively suspended and fixed outwardly, and the vertical height of the groove mold 2 and the groove baffle plate 3 can be independently adjusted respectively, The groove mold 2 and the groove baffle plate 3 on the same side can adjust the relative distance from the body 1 as a whole.

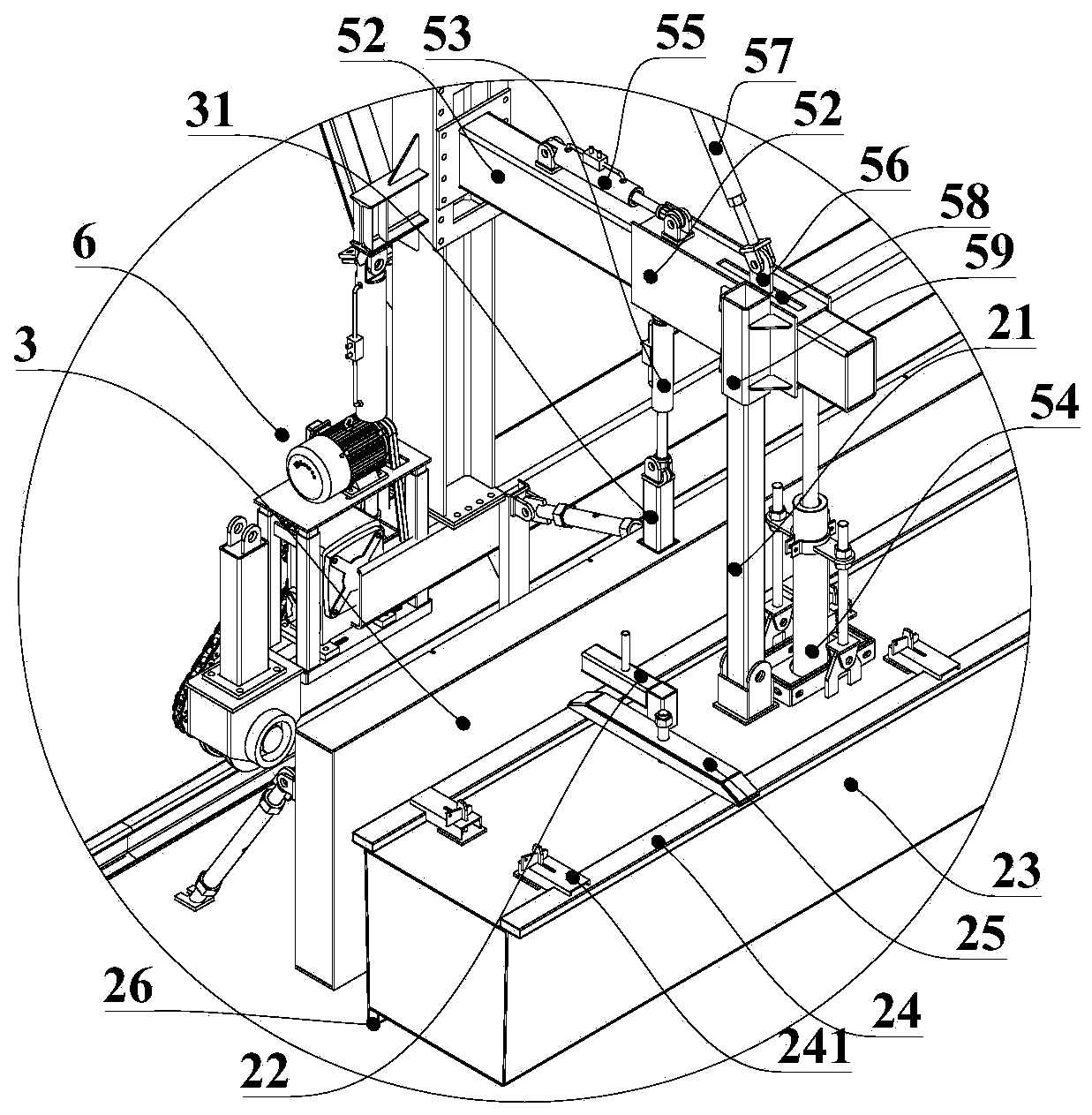

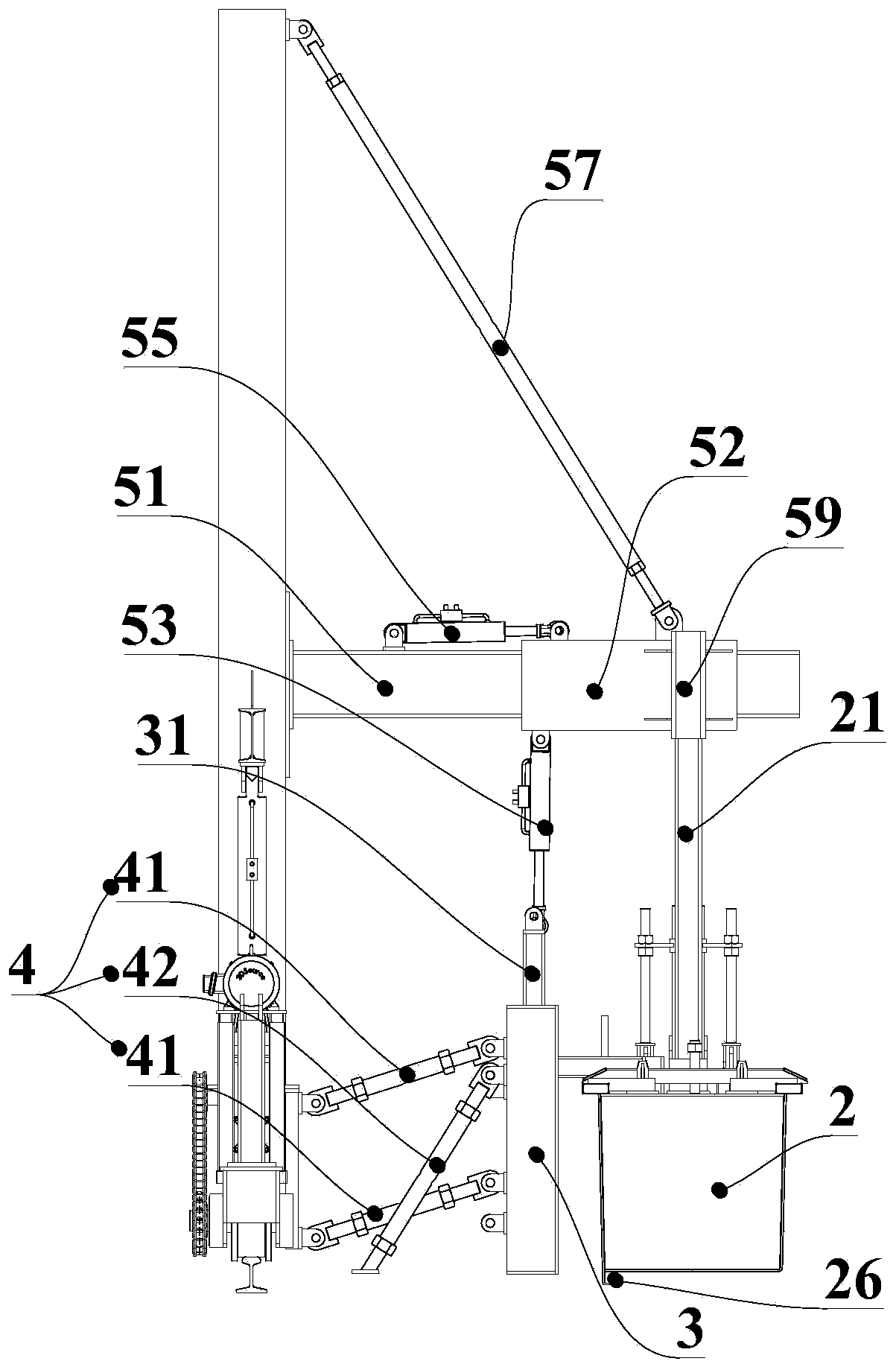

[0025] combine figure 2 and image 3 , the mold 2 includes a mold body 23 for forming the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com