A Laser Projection Type Non-contact Margin Measuring Instrument

A technology of laser projection and laser range finder, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of inconspicuous paper and large measurement errors, and achieve the effect of easy operation and high ranging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

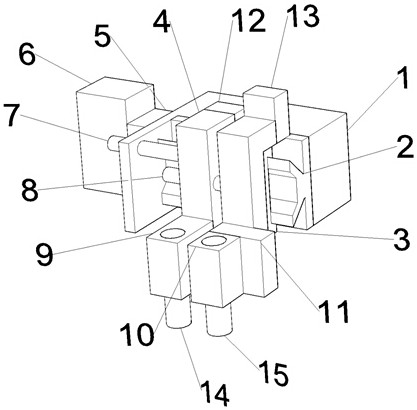

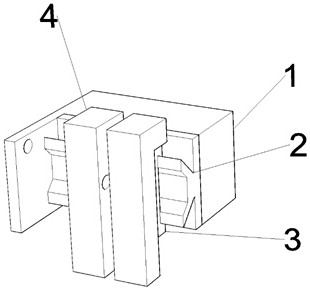

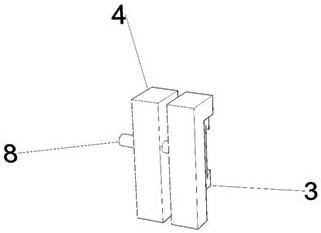

[0034] like Figure 1 to 6 As shown, a laser projection non-contact margin measuring instrument includes a base 1, a track 2, a guide rail a4, a guide rail B3, an adjustable screw A7, an adjustable screw B8, a laser head A14, a laser head B15, Range reflecting table A12, ranging reflecting table B13 and laser range finder 6.

[0035] The track 2 is connected to the base 1. The seat 1 includes a track mounting portion for transversely disposing the track 2, and is perpendicular to the lateral end of the track mounting portion for connecting the adjustable screw A7 and the laser range finder 6. Plate portion.

[0036] The guide rail slider A4 is slidable with the track 2, and the guide rail slide B3 slides to the track 2, that is, the rail slider A4, the rail slider B3 can be moved along the track 2, thereby achieving two The laser X axis is accuratel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com