Turnplow surface pressure sensor isolation box device

A surface pressure and sensor technology, applied in measuring devices, instruments, measuring force, etc., can solve the problems of huge measurement errors, easy errors, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

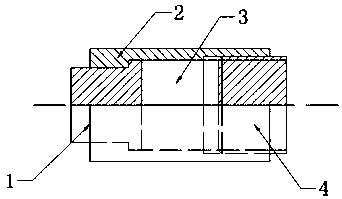

[0015] When installing the isolation box, weld the shell sleeve 2 to the plow surface of the plow, open a hole at the welding place of the plow surface that is as large as the diameter of the support bottom cover 1, and put the support bottom cover 1 into the shell sleeve 2 Inside, the left part of the shell sleeve 2 is designed with a groove, which can make the supporting bottom cover stuck in the welding place between the plow surface and the sleeve 2, and play the role of supporting and protecting the sensor.

[0016] Put the pressure sensing surface of the pressure sensor into the isolation box towards the force-bearing direction of the plowshare surface.

[0017] Tighten the gland 4 to play the role of supporting and protecting the sensor.

[0018] The gland 4 and the sleeve shell 2 are threaded. In order to make the measurement of the plow surface pressure more accurate by the sensor, the gland can be screwed to control the position of the sensor in the space inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com