Temperature sensor and heating appliance component

A technology for temperature sensors and heating appliances, which is applied in the field of temperature sensors and heating appliance components, can solve the problems of complex assembly, many structural parts, and affecting production efficiency, and achieve the reduction of the number of parts, the reduction of installation steps, and the high assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

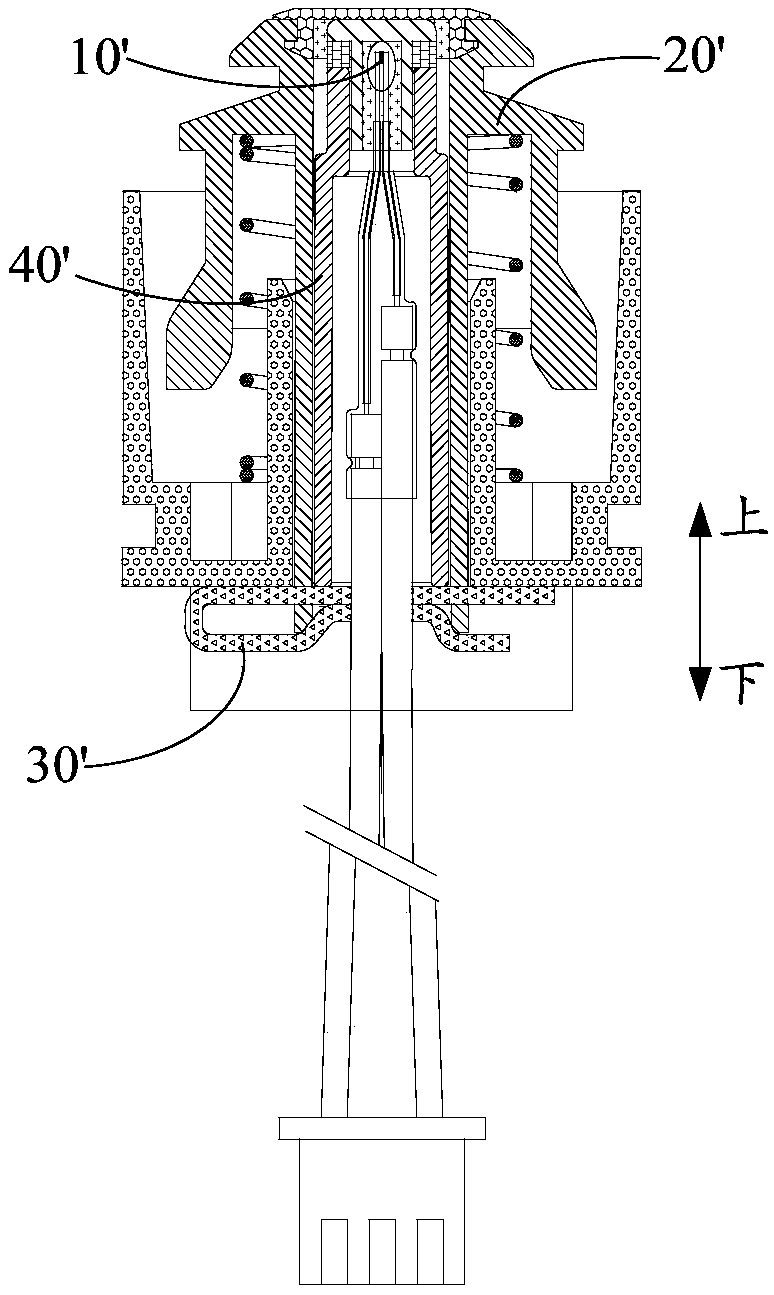

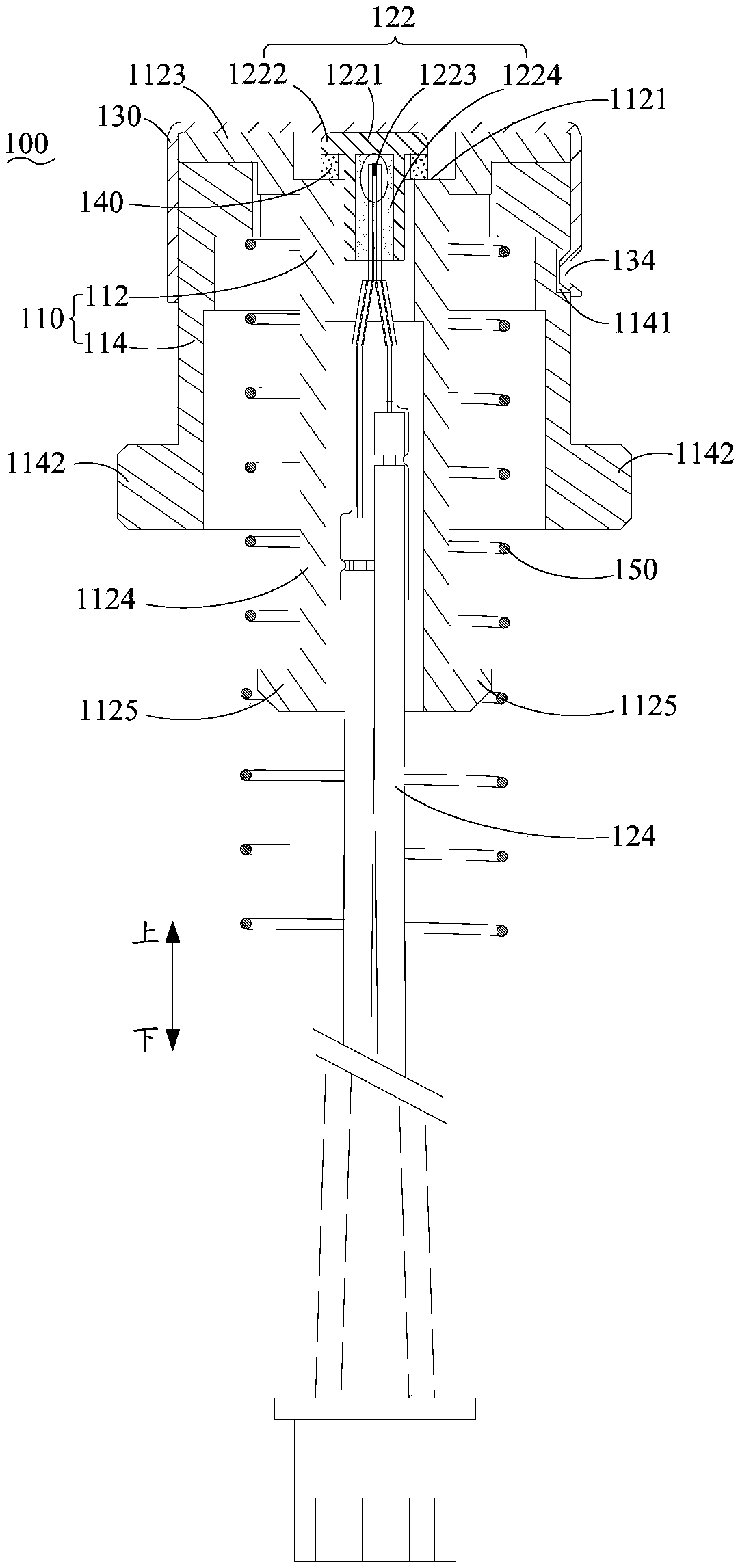

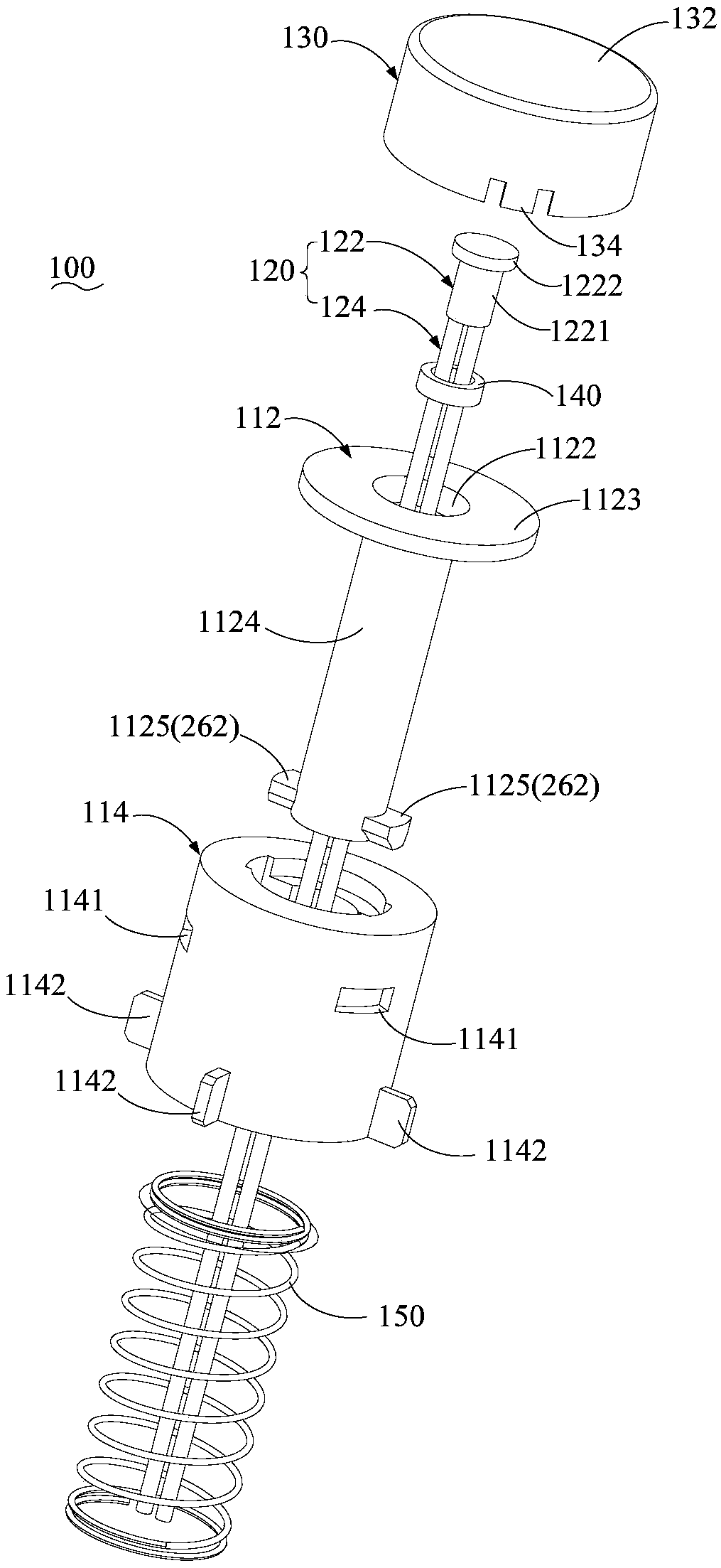

[0104] Specific embodiment one (such as figure 2 and image 3 shown)

[0105] The temperature sensor 100 includes a bracket 110 , a temperature sensing member 120 , a temperature sensing cap 130 , an elastic buffer member 140 and a spring 150 .

[0106] The temperature sensing member 120 includes a lead wire 124 and a temperature sensing module 122. The temperature sensing module 122 is preferably a thermistor module, and specifically includes a housing 1221, a temperature sensing member 1223 and a packaging material 1224. The housing 1221 is preferably a ceramic sleeve, and the housing 1221 is provided with a flange 1222, the temperature sensitive member 1223 is located in the housing 1221, the packaging material 1224 is located in the housing 1221 and the temperature sensitive member 1223 is encapsulated and fixed. It is electrically connected to the lead wire 124 .

[0107] The bracket 110 includes a bracket body 112 and a base 114. The center of the bracket body 112 is...

specific Embodiment 2

[0109] Specific embodiment two (such as Figure 4 to Figure 9 shown)

[0110] The heating appliance assembly is an induction cooker, including the heating appliance 200 and the temperature sensor 100 in the first embodiment.

[0111] The heating appliance 200 includes a panel 210, a coil disk support 220 and a base 230. The temperature sensor 100 is mounted on the coil disk support 220, and the coil disk support 220 is mounted on the base 230. The panel 210 is preferably a microcrystalline plate, and the panel 210 is located on the coil disk. Above the bracket 220 and the panel 210 is provided with a through hole 212 , the temperature sensor 100 passes upward through the through hole 212 and protrudes to the outside of the panel 210 , wherein the part of the temperature sensor 100 located in the through hole 212 is a clearance fit with the through hole 212 .

[0112] A sealing ring 240 is arranged between the panel 210 and the coil disk support 220. There is a glue groove on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com