Shaft workpiece boring and milling clamping auxiliary adjusting device

A technology for shaft workpieces and adjustment devices, which is applied in positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of easy occurrence of safety accidents, lifting force, time-consuming and labor-intensive, etc., so as to reduce lifting operations and labor intensity. , Adjust the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

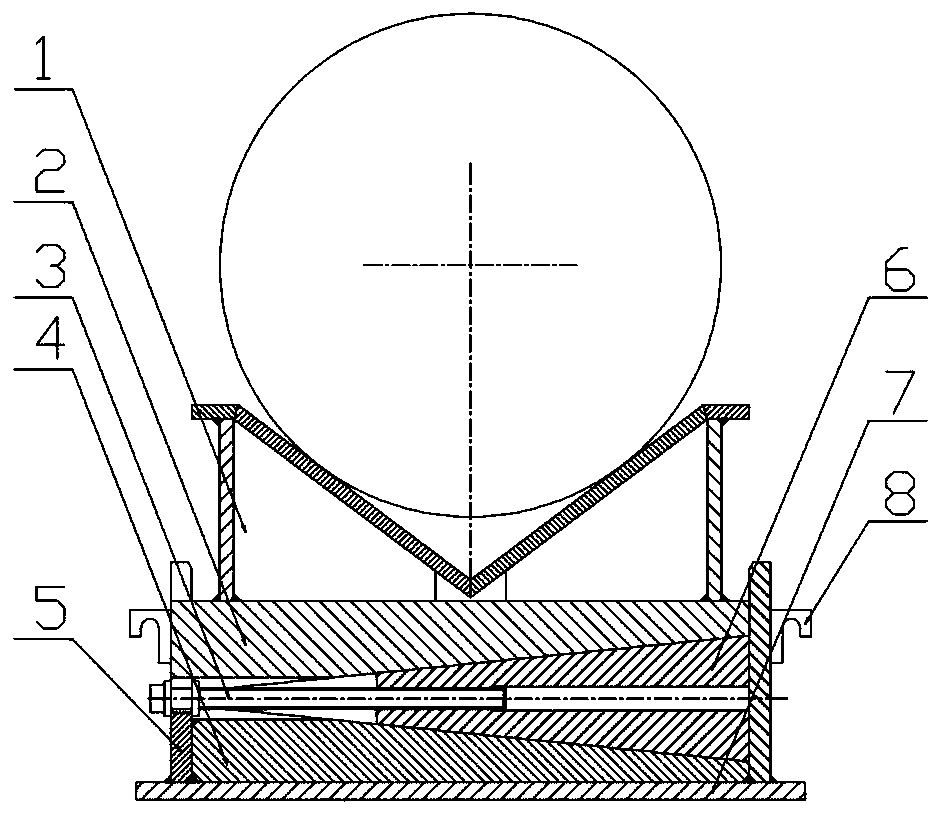

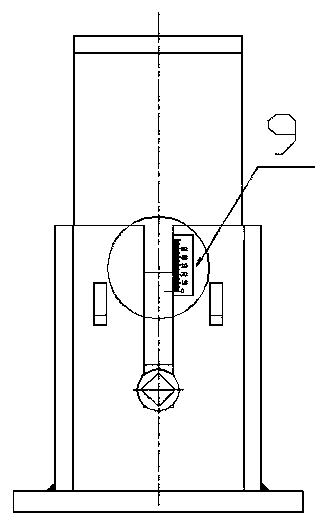

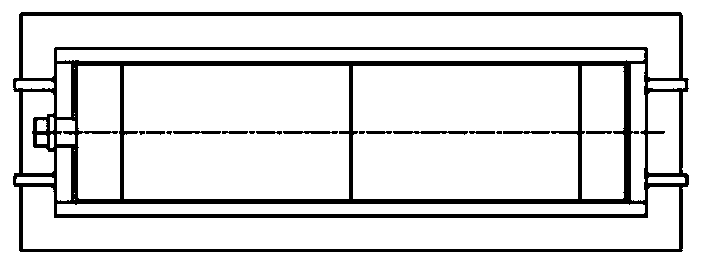

[0029] Refer to attached Figure 1-11 , an auxiliary adjusting device for boring, milling and clamping of shaft workpieces, comprising a V-shaped pad iron 1, a movable inclined iron 2, a fixed inclined iron 4, an adjusting bolt 3, a baffle plate 5 and an adjusting inclined iron 6, the movable inclined iron 2 and the fixed inclined iron The section of the inclined iron 4 is a right triangle, the section of the adjustable inclined iron 6 is an isosceles trapezoid matched with the movable inclined iron 2 and the fixed inclined iron 4, and the adjustable inclined iron 6 is arranged between the movable inclined iron 2 and the fixed inclined iron 4 Between them, the movable inclined iron 2, the adjusting inclined iron 6 and the fixed inclined iron 4 are stacked up and down together to form a cuboid, and baffles 5 are arranged around the cuboid, the V-shaped parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertex angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com