Device for safely laying fiber grating sensors and construction method

A technology of fiber grating and construction method, which is applied in the direction of converting sensor output, using optical device to transmit sensing components, measuring device, etc. During the grouting process), pressing on the sensor, affecting the response sensitivity of the fiber grating, and breaking the fiber grating sensor probe, to achieve the effect of ensuring the grouting effect, wide selection range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

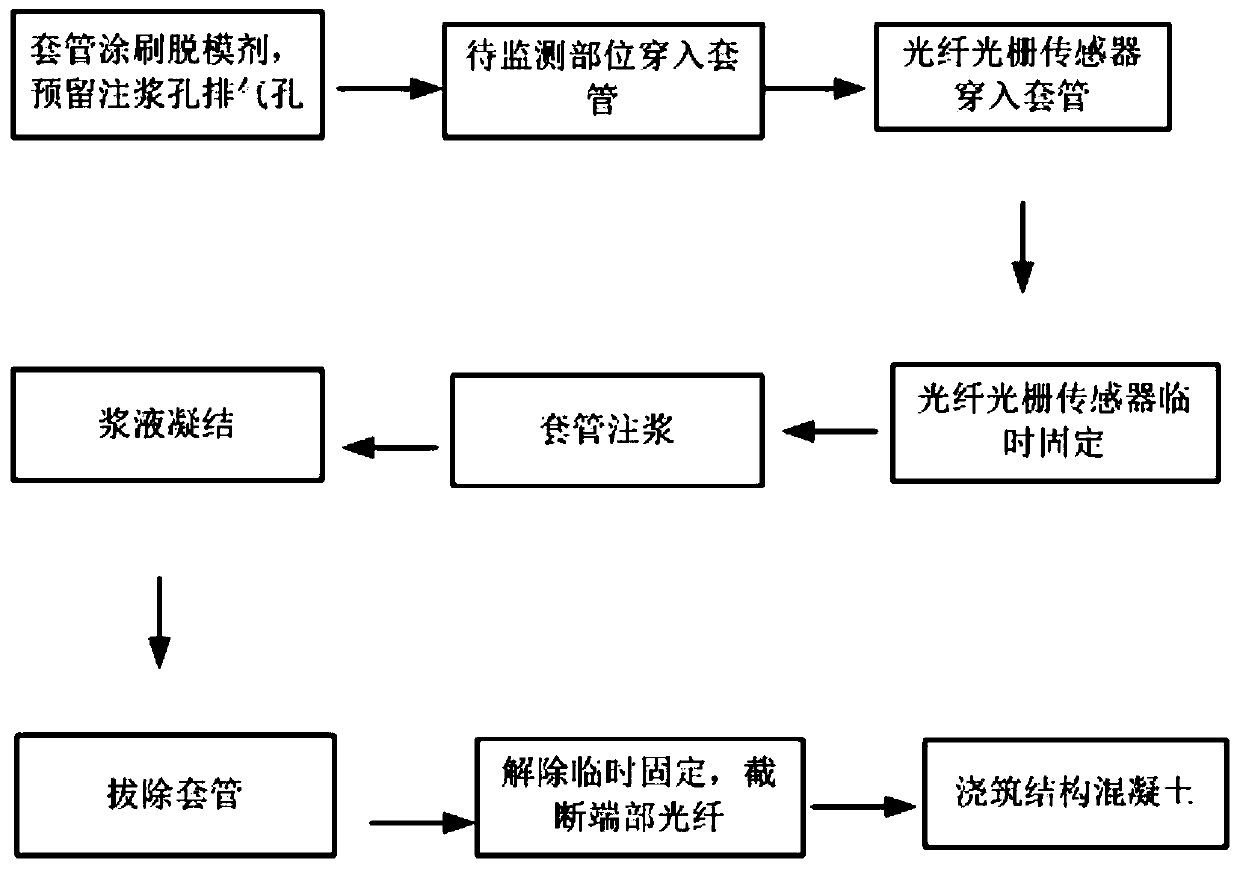

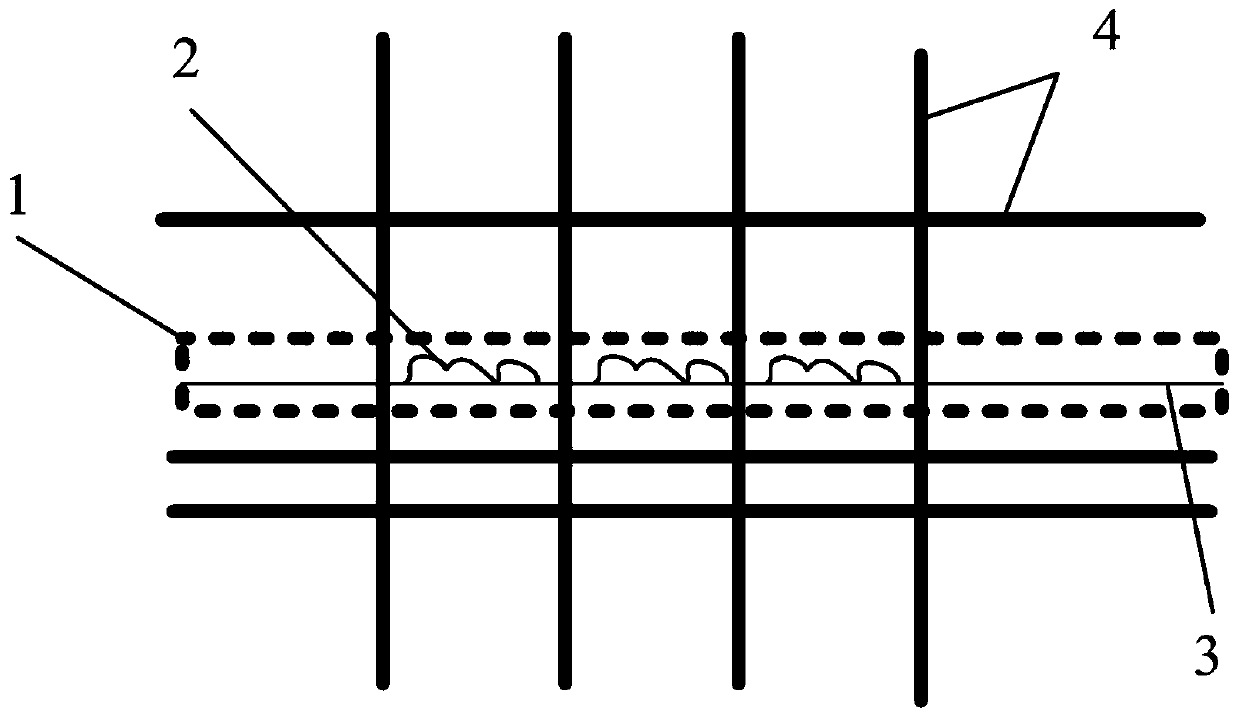

[0034] Combine below figure 1 and figure 2 , detailing the structural composition of the device for safely deploying fiber grating sensors of the present invention.

[0035] Please refer to figure 1 and figure 2 , a device for safely deploying fiber grating sensors, including a thin-walled protective sleeve 1 and a reserved hole arranged at the site to be monitored in a concrete structure, the thin-walled protective sleeve 1 is provided with a grouting hole and an air vent, and the thin-walled The inner wall of the protective casing 1 is evenly coated with a release agent, the fiber grating sensor 2 penetrates into the thin-walled protective casing 1, and its two ends are temporarily fixed, and the grouting holes are used for pouring cement mortar.

[0036] Specifically, the device and construction method for safely deploying fiber grating sensors in this embodiment adopt the construction technology of first threading beams, then grouting, and then pouring concrete. First...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap