Air duct structure and air conditioning system

An air duct and air inlet technology, which is applied in the field of air duct structure and air conditioning system, can solve the problems of small adjustable range of air coverage space, small air volume adjustment range, and small air outlet status, and achieves large adjustable range and air volume. The effect of large adjustment range and many air outlet states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

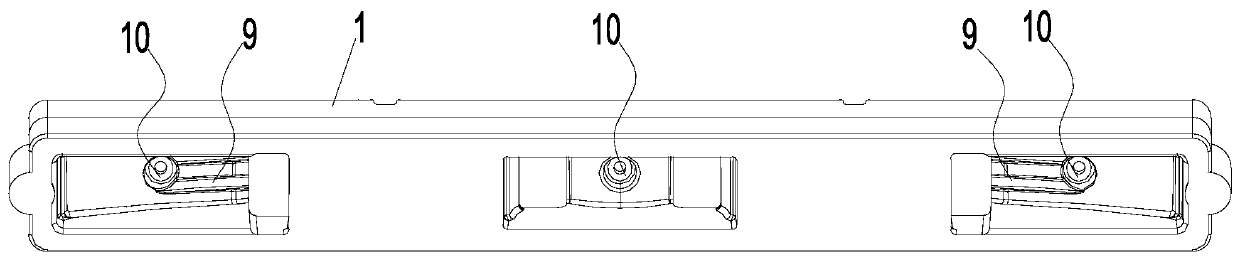

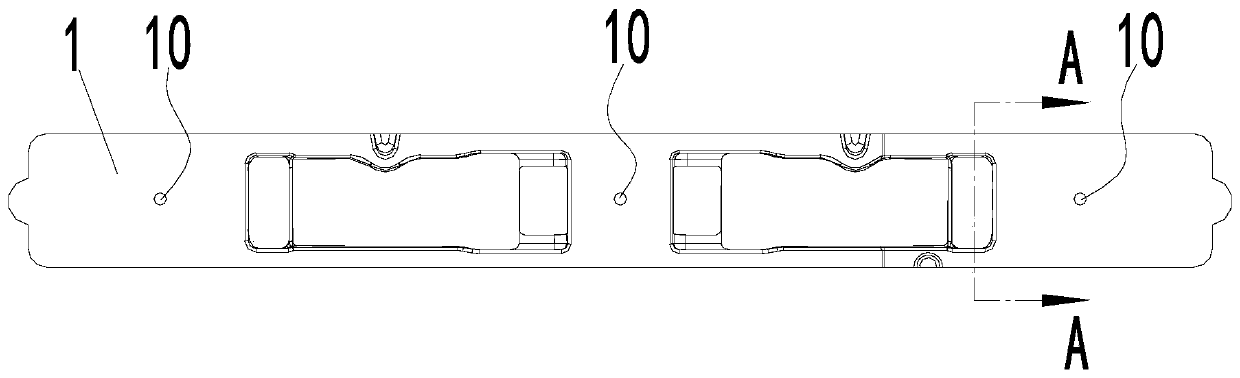

[0048] This embodiment provides an air duct structure for guiding and distributing air from an air conditioner. The air duct structure includes a housing 1 and a first block 2. One side of the housing 1 is provided with an air inlet. The other side of the casing 1 is provided with an air outlet, the air inlet corresponds to the air inlet side, and the air outlet corresponds to the air outlet side. The number of the first block 2 is at least two, and the first block 2 is arranged at the air outlet and divides the above air outlet into several sub-air outlets.

[0049] With this structure, the wind coming in from the air inlet will be blown out from different sub-air outlets, the first block 2 plays a role in guiding and diverting the wind, the number of the first block 2 is at least two, and all The first block 2 is installed in the middle of the air outlet, so that the number of sub-air outlets formed is at least three. Therefore, when the air duct structure provided by this e...

Embodiment 2

[0052] This embodiment is further improved on the basis of Embodiment 1. The air duct structure provided by this embodiment also includes a second block 6, which is located in the middle of the air inlet, so as to The air inlet is divided into two sub-air inlets with the same flow rate. It is worth noting that the above-mentioned second block 6 is a conical block, and the conical tip of the second block 6 faces the inside of the air duct structure. The second block 6 is integrally formed with the shell 1 and the first block 2, and the first block 2, the second block 6, and the shell 1 are structural members made of foam, specifically, the entire air duct The structure is cast using a mould. The second block 6 is also provided with the aforementioned screw holes 10 .

[0053] The number of the above-mentioned first block 2 is two, and the two first blocks 2 are symmetrically arranged at the above-mentioned air outlet, thereby dividing the air outlet into three sub-air outlets...

Embodiment 3

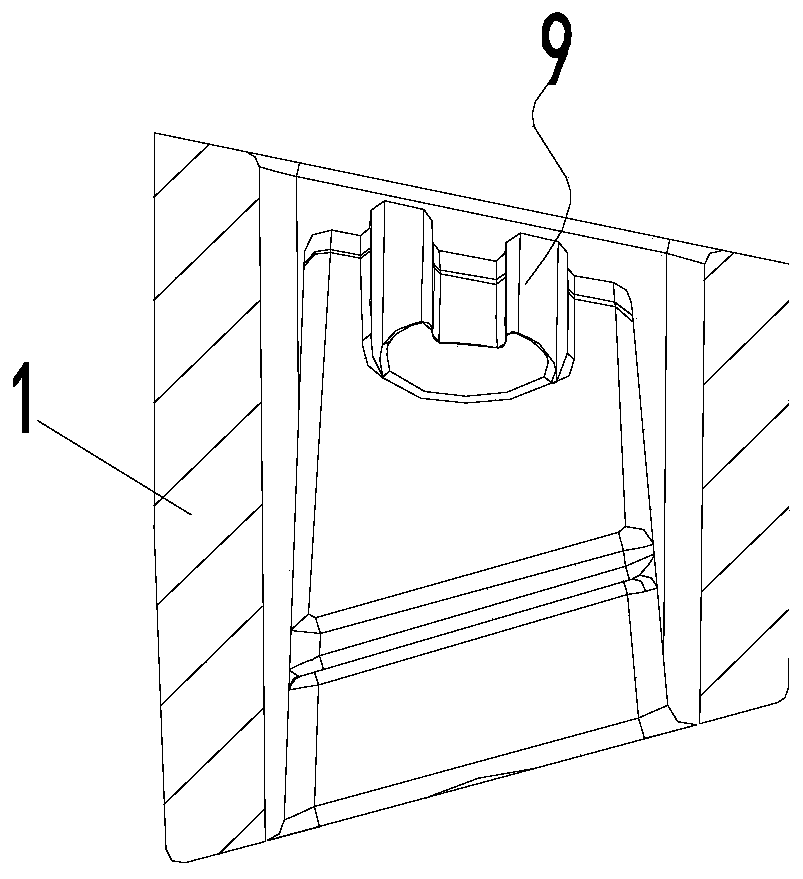

[0065] This embodiment is a more optimal implementation of the above-mentioned embodiment. In this embodiment, the side of the first block 2 close to the air inlet is defined as the windward surface 21. In the air duct structure provided by this embodiment, the first block The windward surface 21 on 2 is a curved surface inclined toward the housing 1, that is, the distance between the side of the curved surface close to the housing 1 and the air inlet is smaller than that of the side away from the housing 1.

[0066] With this structure, a smooth and even wind distribution effect can be obtained.

[0067] As the best implementation mode of this embodiment, in this embodiment, the above-mentioned curved surface (that is, the windward surface 21 on the first block 2) is a wave surface, specifically, the curved surface is composed of a first arc surface, a second arc surface and the third arc surface in sequence, the centers of the first arc surface and the third arc surface are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com