Lower switching valve device for detecting air tightness of precise three-way valve

A technology of air tightness detection and three-way valve, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, workpiece clamping device, manufacturing tools, etc. It can solve the problem of easy falling off of the rotary valve and achieve air tightness The effect of testing and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

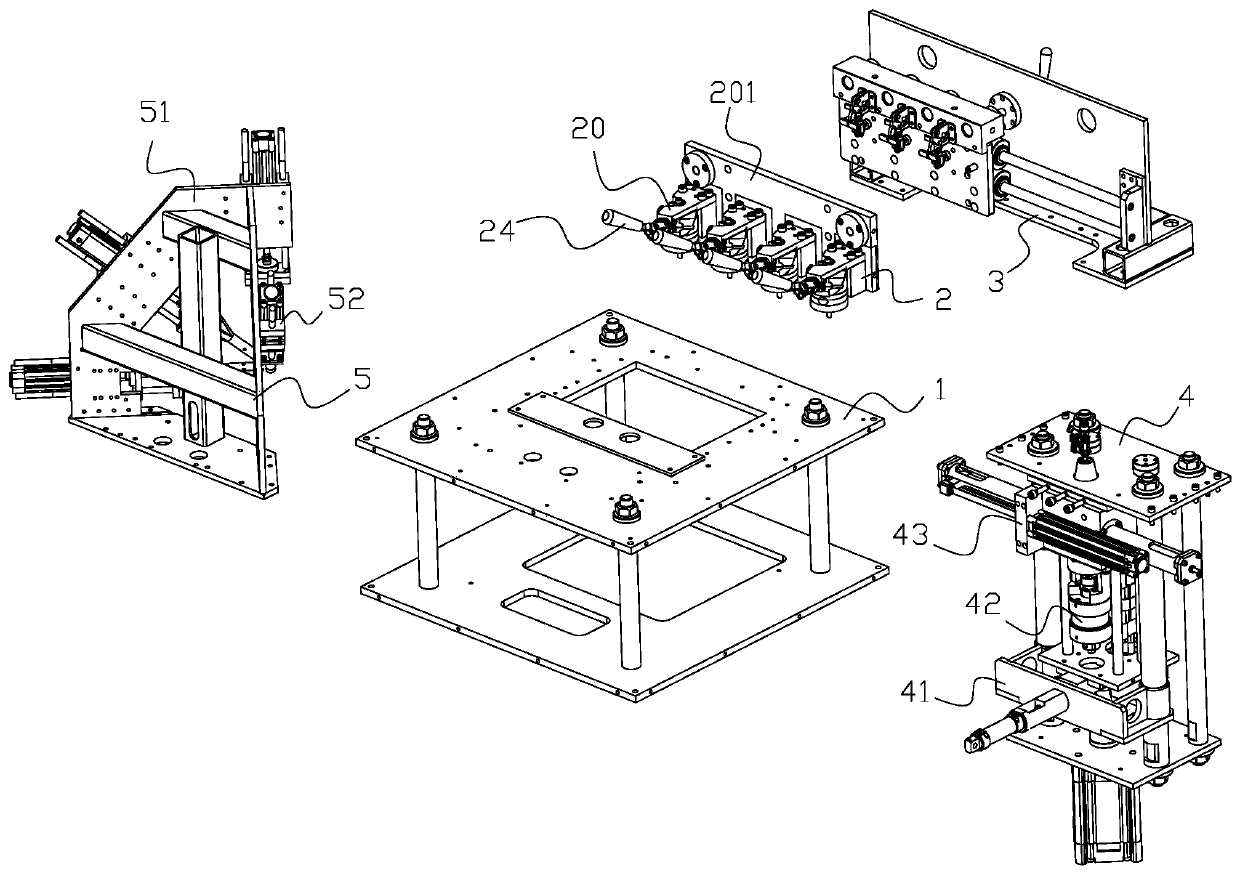

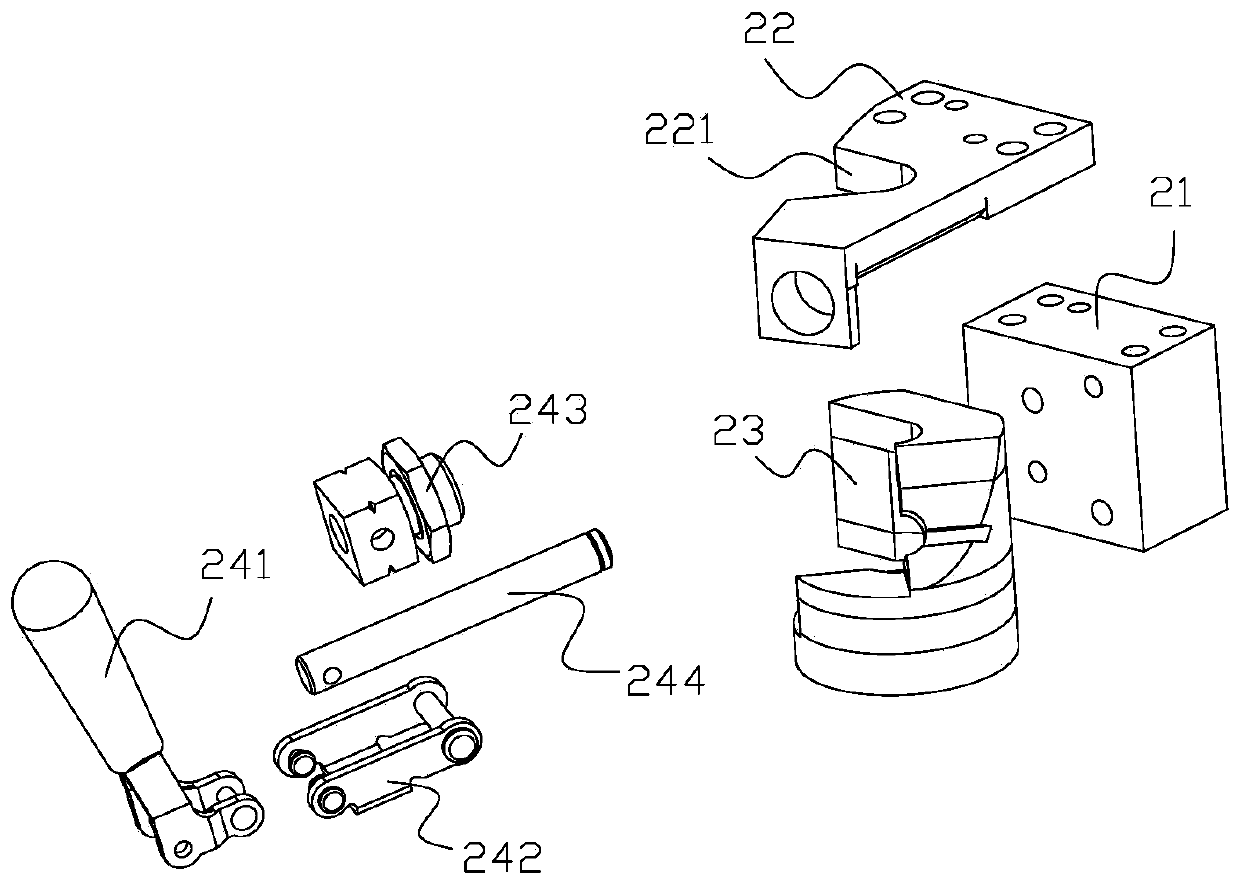

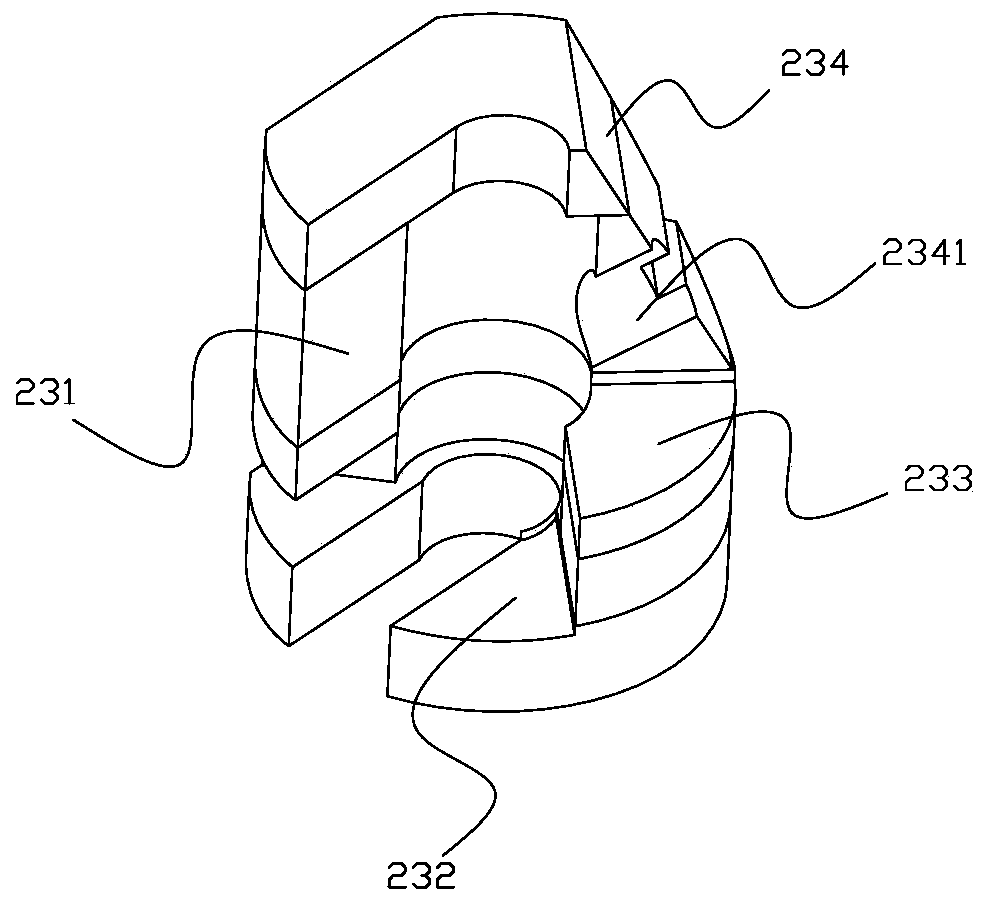

[0020] Such as figure 1 As shown, a precision three-way valve air tightness testing equipment, the equipment includes a frame 1, jig tooling 2, jig moving positioning device 3, lower switch valve device 4 and detection device 5. The jig tooling 2 is installed on the jig moving positioning device 3. The jig tooling 2 includes a jig mounting plate 201 and four jig mechanisms 20 thereon for installing three-way valves. A plurality of jig mechanisms 20 can reduce the The number of loading and unloading of the three-way valve improves the efficiency of detection. The jig moving and positioning device 3 is arranged on the frame 1 , and the jig moving and positioning device 3 is used for moving and positioning the jig tooling 2 . The lower switching valve device 4 includes a vertical movement mechanism 41 , a clamping mechanism 42 and a valve switching mechanism 43 . An up and down movement mechanism 41 is provided in the frame 1 . The clamping mechanism 42 is arranged on the up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com